The patented Crossover dredge Ball Joint includes two replaceable wear liners which provide a streamlined and unrestricted flow area in any tilted position. The optimal flow conditions result in reduced flow resistance and major cost-savings in fuel and wear, which typically result in a very short return on investment.

Classic Ball Joint

The Classic dredge ball joint has proven its worth for over 30 years. It is known for its sturdiness, ease of connecting and simplicity. The design includes one replaceable wear liner in the case. The inside of the ball is protected by the dredge pipe, which runs through the ball.

The specifications of our Pipe Joint

A.General

High accuracy, fully welded, painted construction can be easily integrated into the side Suction Pipe of all hopper dredgers. The joints enable the cardanic joint to pivot in both the horizontal and the vertical plane.

The pivots are executed as steel shafts with bushes and have sufficient strength to bear the full load of the side suction pipe. A rubber fender is mounted on the cardanic ring to prevent damage to the hull.

To facilitate the pivoting movement of the joints, a Rubber Hose with wear lining is fitted between the connecting pipe pieces. The hose is fitted with steel rings to provide strength against the vacuum of the Dredge Pump.

B. Construction and procedure

The construction is to be built according to the drawing with rules of good workmanship.

The construction consist joint, rubber hose, cardan ring, which are carefully manufactured and checked to ensure total dimension.

C. Materials

All steel used to be blasted and shop primed both sides. Using Q345D, DH36

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

D. Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

Welding seam preparation, welding method, welding material and consequent preheating temperature acc. to UniSite standards and approved by clients.

E. Workmanship

The workmanship have good marine practice. Care are taken to ensure fair lines, smooth surfaces and neat welding.

UniSite`s core activity: serve for dredging and marine projects

Provide service and relevant parts for dredgers, including Dredger construction, repairing and maintenance.

Provide items for dredging, land reclamation, offshore, marine engineering, piling works,municipal engineering, mechanical,engineering, oilfield projects and environmental remediation projects.

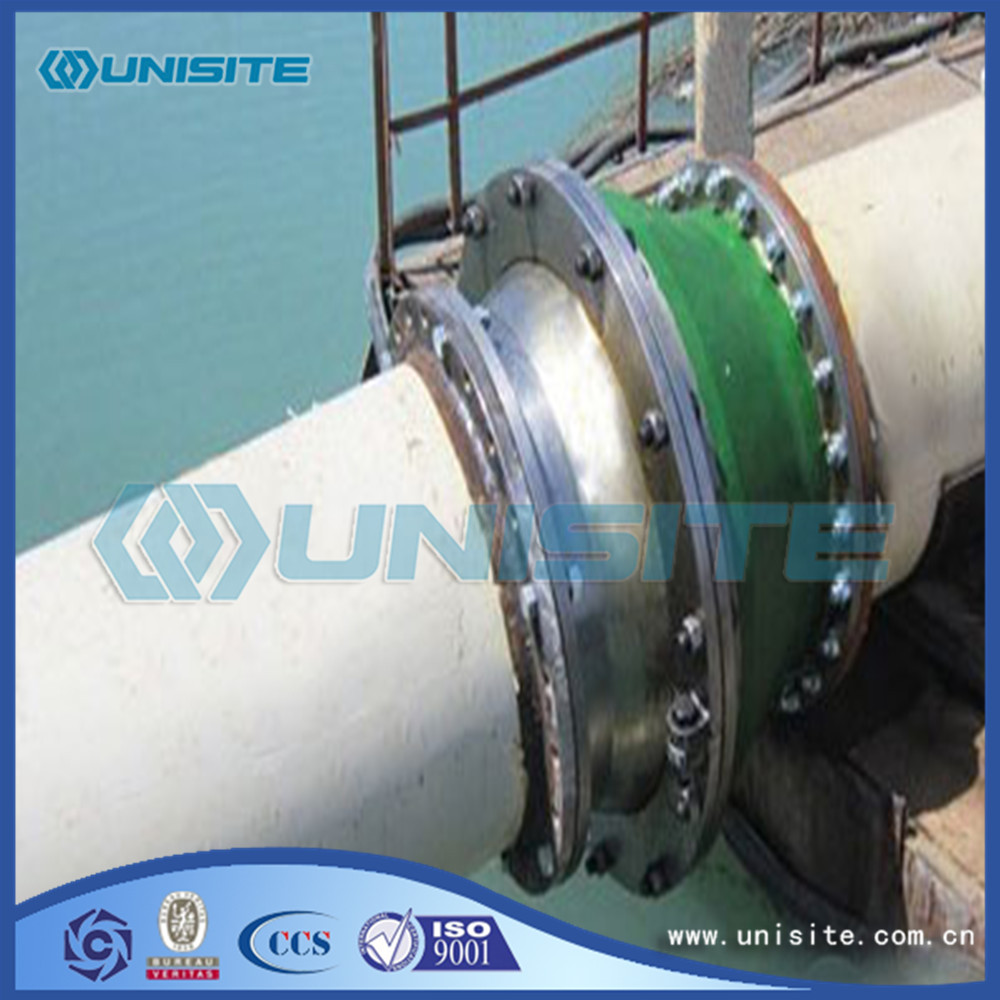

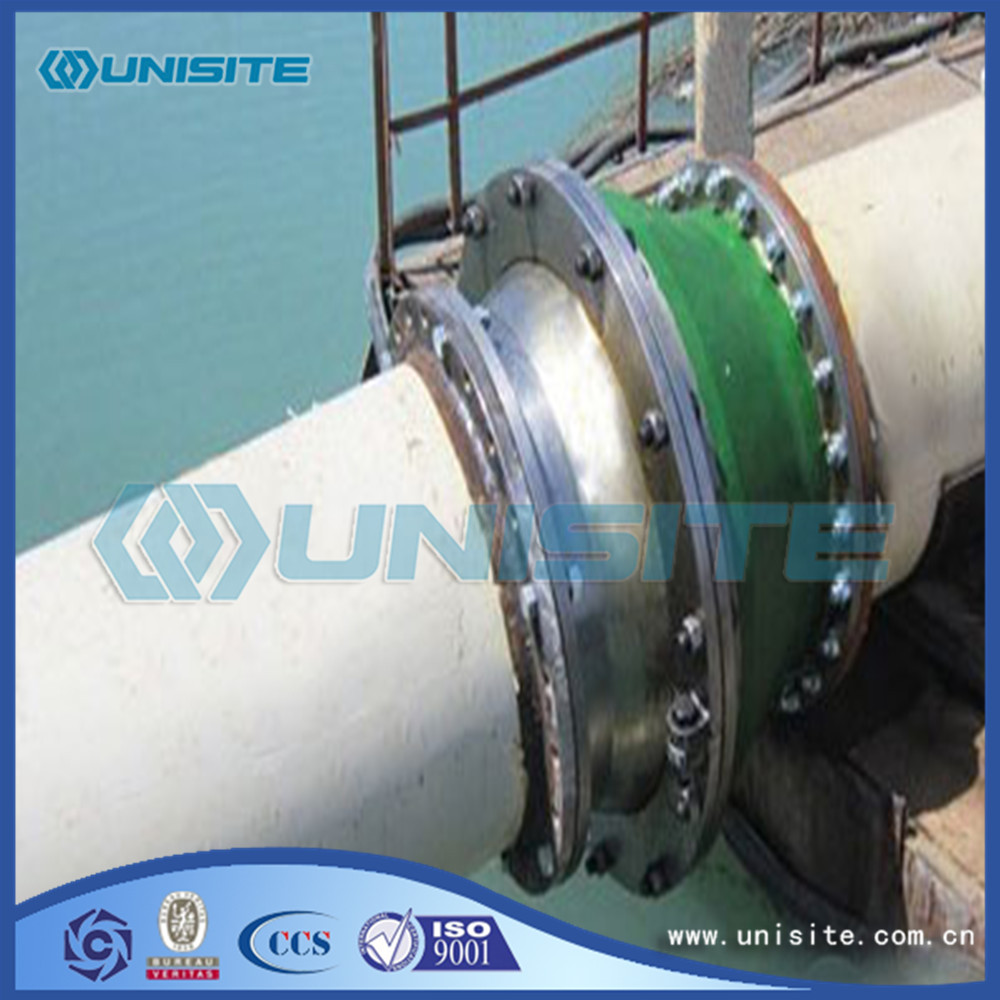

Photos of our Front Lower Ball Joint

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Structures > Ball Joint