General carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum, plastic, argon Ge Lek, pvc and other materials produced.Casting Branch Pipe is a three hole, namely an inlet and two outlet; or two inlets, a kind of chemical pipe outlet, there are T-shaped and Y-shaped, with equal diameter nozzle, orifice diameter pipe also, for three identical or different line Survey Office. The main role tee is to change the direction of flow.

Divided by technology

1. hydroforming

Tee hydroforming is compensated by the axial expansion of the metal material of a Branch Pipe forming process. The process is the use of special hydraulic machine, the injection of the liquid and the inner diameter equal to the three-way tube, side cylinder synchronous movement of the extruded tube by two horizontal hydraulic presses, tube after extrusion by the smaller size, the inner tube the volume of liquid with the smaller tube and pressure rise, when it reaches the three-way manifold pressure required for the expansion, the metal material in the dual role of the cylinder and the inner tube side fluid pressure and flow along the mold cavity bulge manifold.

Tee hydroforming process can be a shape, high production efficiency; competent and shoulder tee wall thickness were increased.

Due to the larger seamless tee hydroforming process equipment required tonnage currently mainly for the manufacture of standard wall thickness less than DN400 tee. Its application for the molding material is relatively low work hardening tendency of low-carbon steel, low alloy steel, stainless steel, including some non-ferrous materials, such as copper, aluminum, and titanium.

2. thermoforming

Thermoforming tee tee is greater than the diameter of the tube, flattening about to tee diameter size,

Our products all over the world:

1. 2005 Palm island construction in Dubai: the large quantities of dredging pipeline including sink pipes, shore pipes with flanges and pontoons

2. 2005 Waterways dredging projects : the large quantities of pipeline, connected pontoons.

3. 2006 Waterways dredging projects: the large quantities of pipeline, connected pontoons.

4. 2007 Waterways dredging projects: the large quantities of pipeline, including sink pipes, shore pipes with flanges and pontoons.

5. 2008 Waterways dredging projects: the large quantities of pipeline, connected pontoons, floating pipelines and bends.

6. 2008 Capital dredging for a third berth at Anderson point in port Hedland in Australian: the large quantities of lsaw pipes

7. 2009 Waterways dredging projects: the large quantities of pipeline, connected pontoons and bends.

8. 2010 Environmental works:pontoon for work platform and pipes

......

and till now, above just a little projects we involved in.

Assure for large production capacity with many advanced equipment

Integrate all resources, UniSite have large advanced equipment and is able to do most large products of marine products including pontoons

Bending machining, rolling machine with 150mm, SAW equipment, manual welding equipment, Laser Thermometer, Electrode dryer, cutting machine, milling machine, electrical element, big Welding roller stand, Box -type electric furnace, special inspection tools, Lifting Gantry 200T, 100T, floating crane 1200T-

With professionalism, vitality, innovation, respect, team spirit, UniSite culture (corporate values, corporate philosophy and behavior shaping) is continuously developing, along with our company from its foundation.

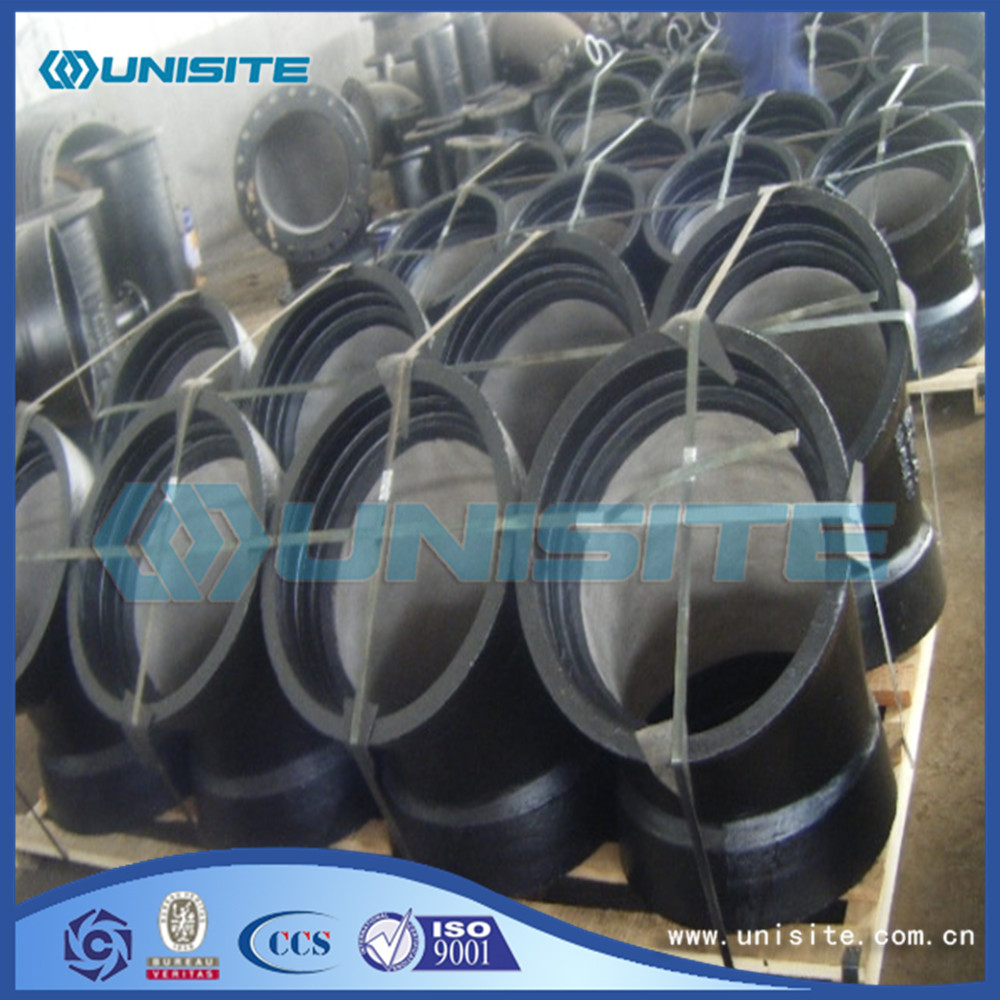

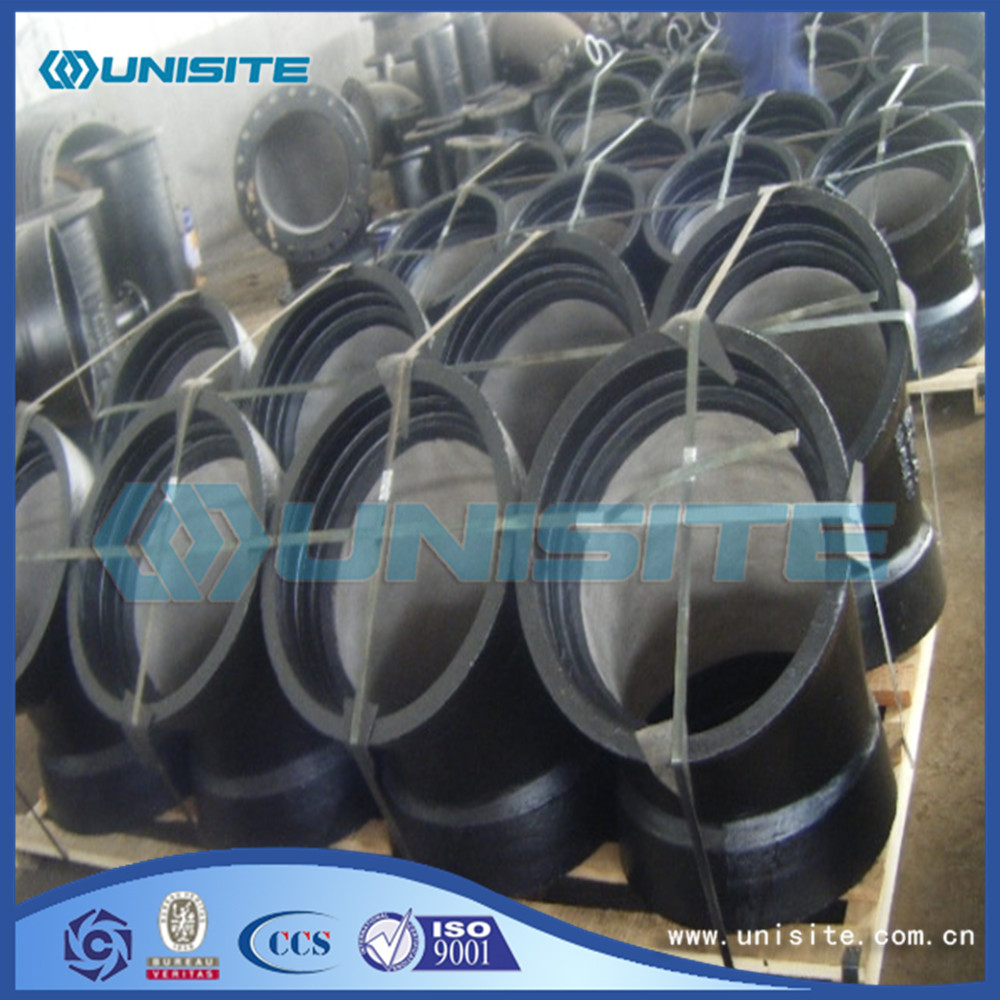

Photos of our Custom casting branch pipe

Our service

Besides above the general specifications, we can also supply some specific anchor and other similar Casting Bend as clients' requirements.

Package and shipping

bulk package and bulk vessel transportation

container package and container transportation

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Structures > Casting Branch Pipe