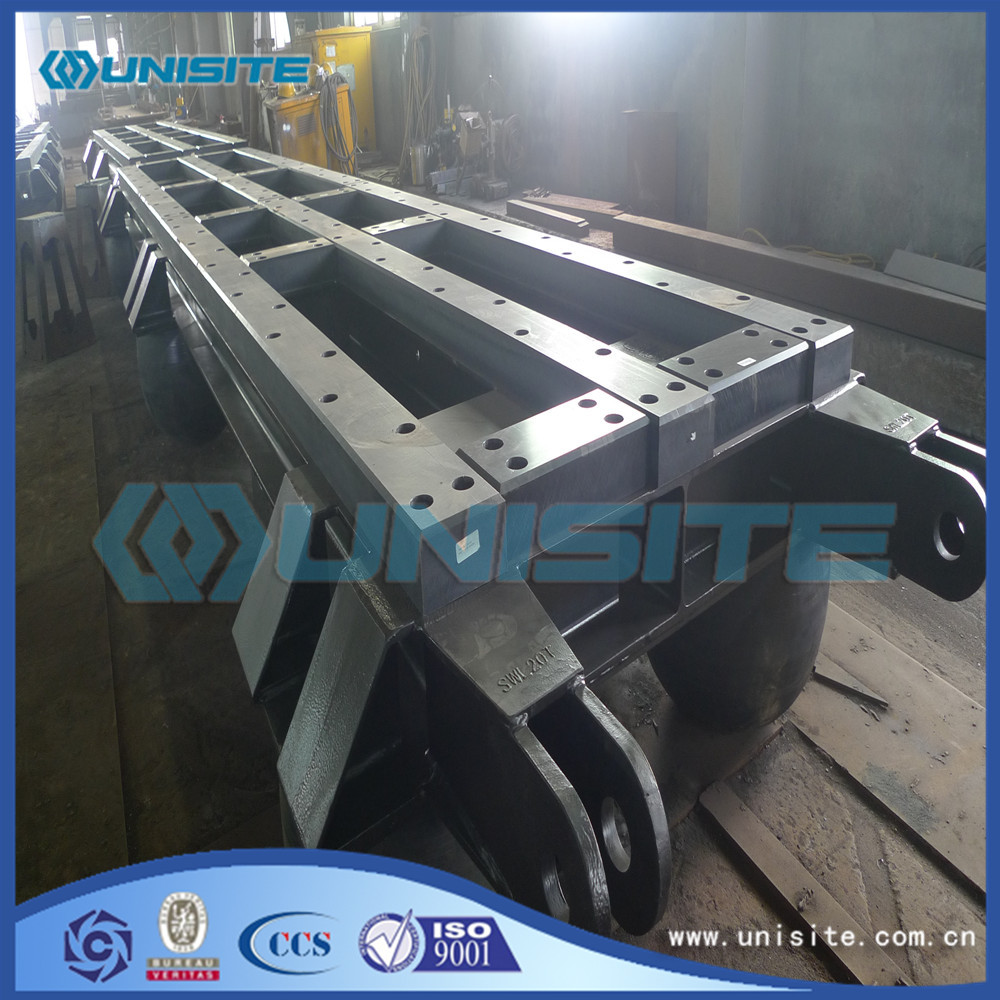

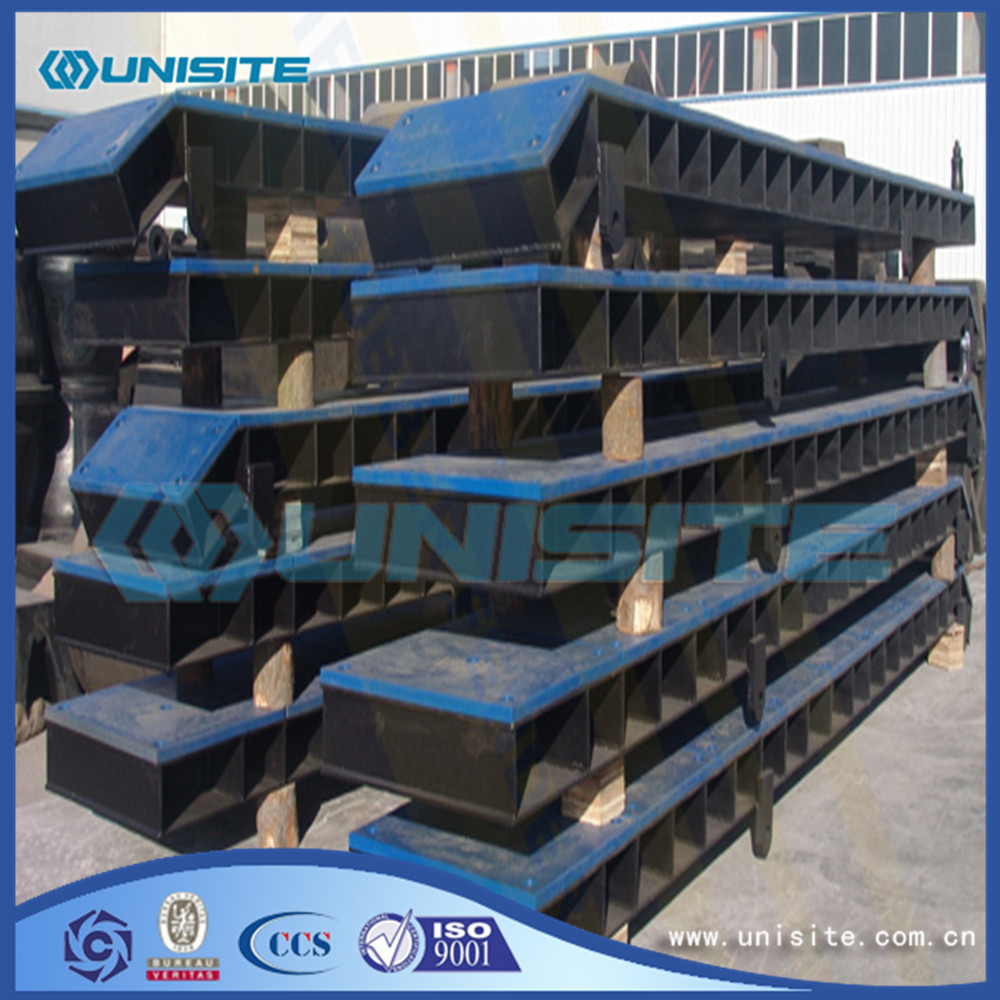

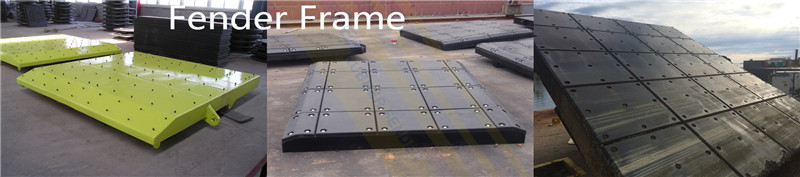

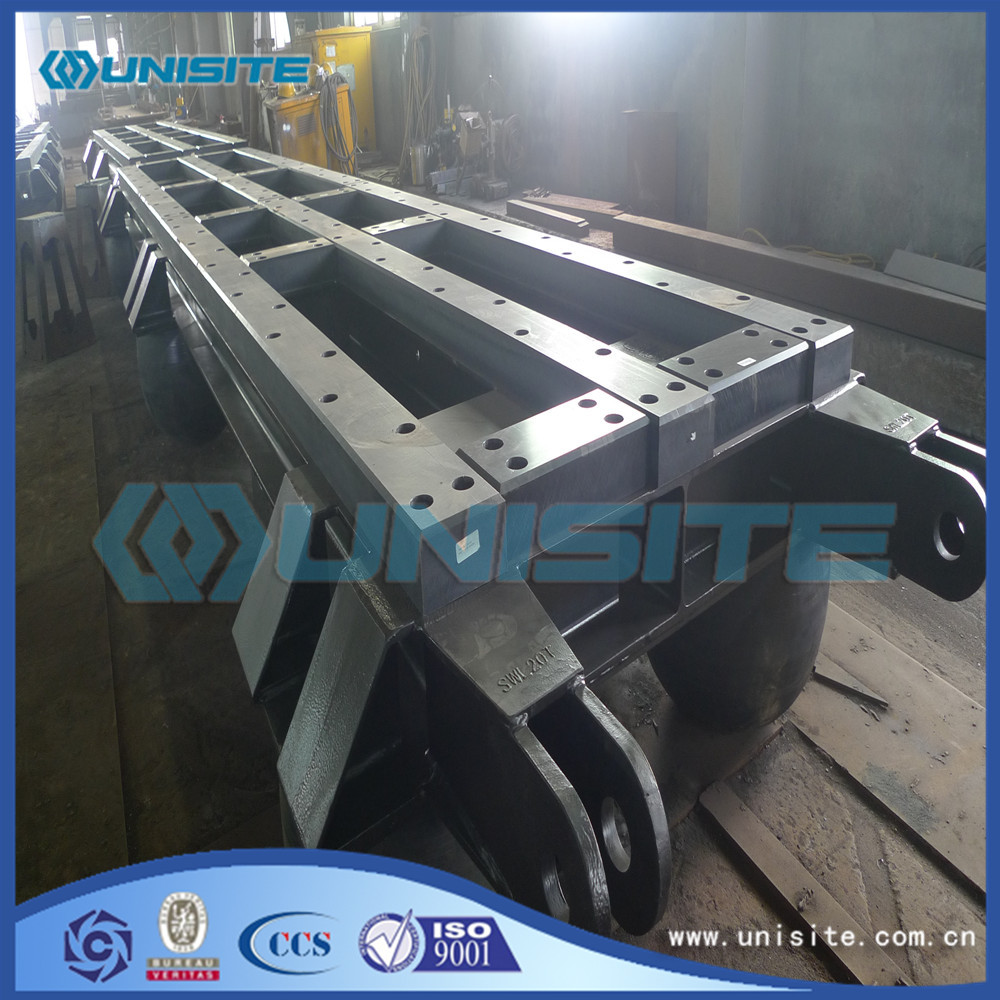

High-demanding welded and High Strength Fender Frame, assembled with UHWM-PE sliding block and fender ball, can be used for engineering ship, used to prevent collision and protect the ship or port. The construction is to be built according to the drawing with rules of good workmanship.

Materials All fabricated steelwork used in the construction will be to manufacturing standard of classification society.

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

Workmanship

The workmanship have good marine practice. Care are taken to ensure fair lines, smooth surfaces and neat welding.

Main particulars

| | MAIN PARTICULARS |

| Tolerance | High accuracy(ISO2768, ISO5817, ISO13920) |

| Material | S235JR-S355J2G3+rubber+UMHW-PE |

| Dimension(L*B*H) | As per drawing, as large as we can |

| Weight | 3Ton~8Ton |

| Coating | Sa2.5 blasted and two or three layers painted with highest quality |

| Marking | as per clients' requirements |

| Inspection | material, construction, dimension, welding seam, non defective test, paint inspection, rubber inspection, PE inspection |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Quality control department

Whether we are able to offer our client best possible and most sustainable solutions to their requirement or to complete our mission, our safety & quality are the key factors. So that quality, health, safety and environment (QHSE) on site are given priority which includes setting our QHSE standards and production guidelines, in-house safety training to our staff, checking all the production equipments periodically, preventing pollution, accidents and health hazards, auditing and verifying whether our work is being executed according our certified system ISO 9001, CCS certificate, BV certificate.

We a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

We also organize site short meetings (SSM) when new productions and activities are being under taken and when working plans, technologies, qualities and methods are altered.

Thanks to these efforts and activities, we are able to perform our best works in an efficient way.

Technology

Offering our client best possible and most sustainable solutions to their requirement. Production procedure:

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Other procedure if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Machining if necessary;

Step7: Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step8: Package, Loading and Lashing when delivery;

UniSite`s core activity: serve for dredging and marine projects .Provide service and relevant parts for dredgers, including Dredger construction, repairing and maintenance.Provide items for dredging, land reclamation, offshore, marine engineering, piling works, municipal engineering, mechanical engineering, oilfield projects and environmental remediation projects.

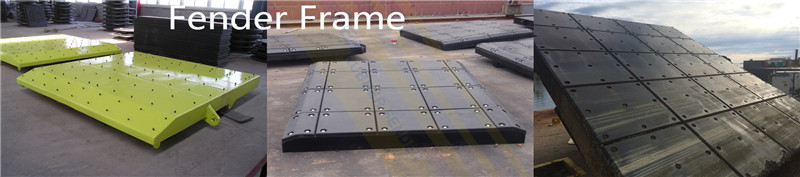

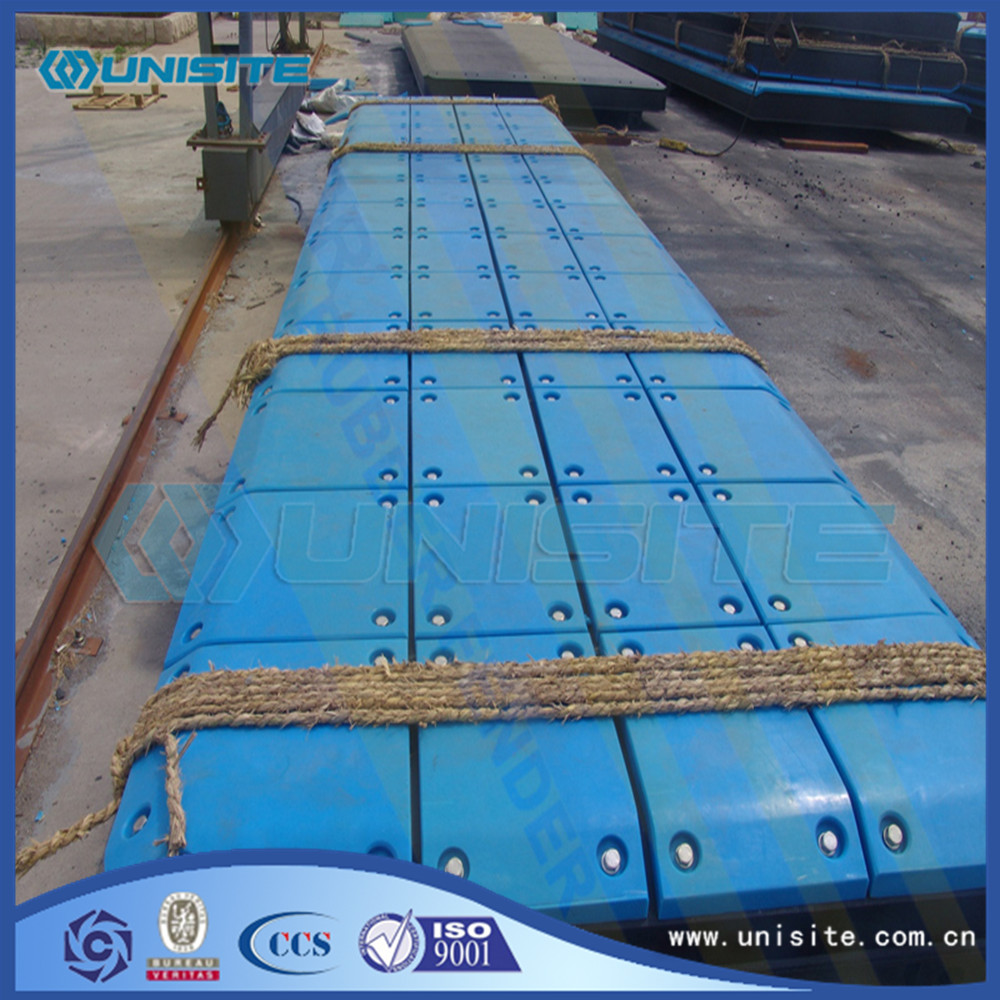

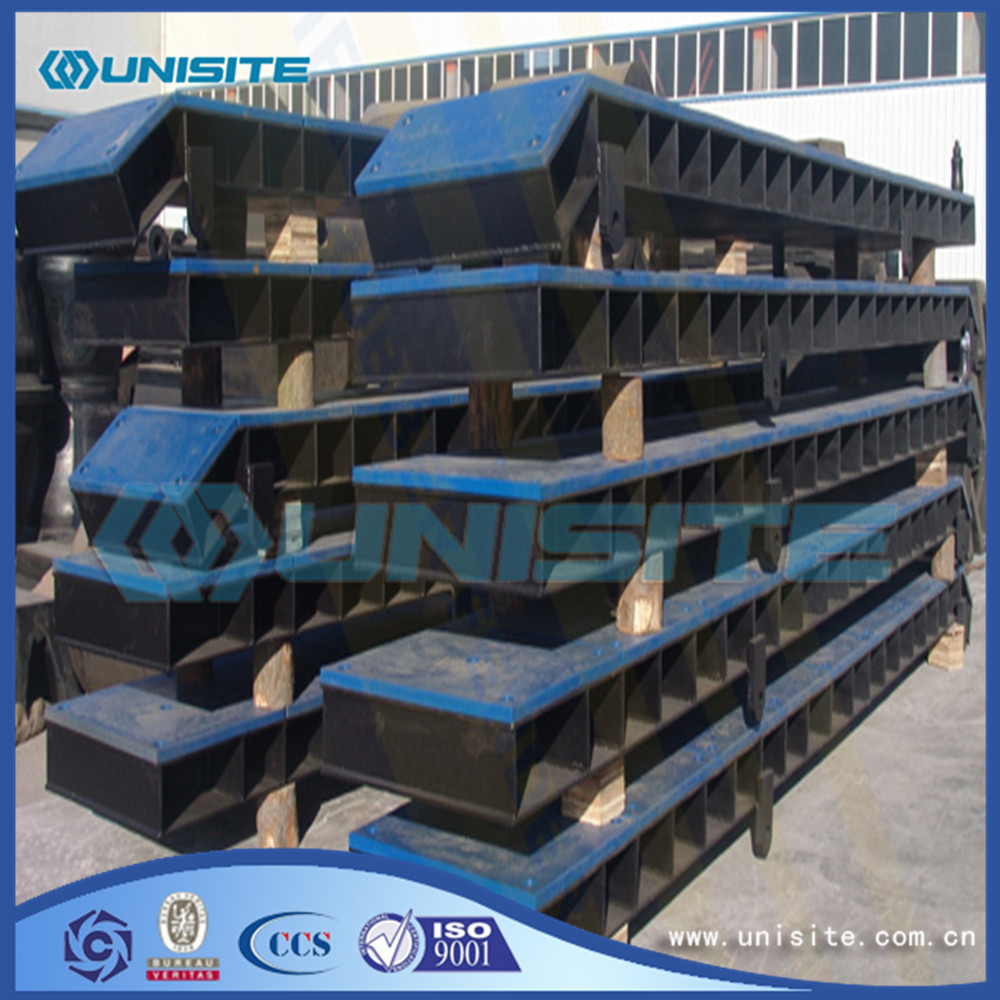

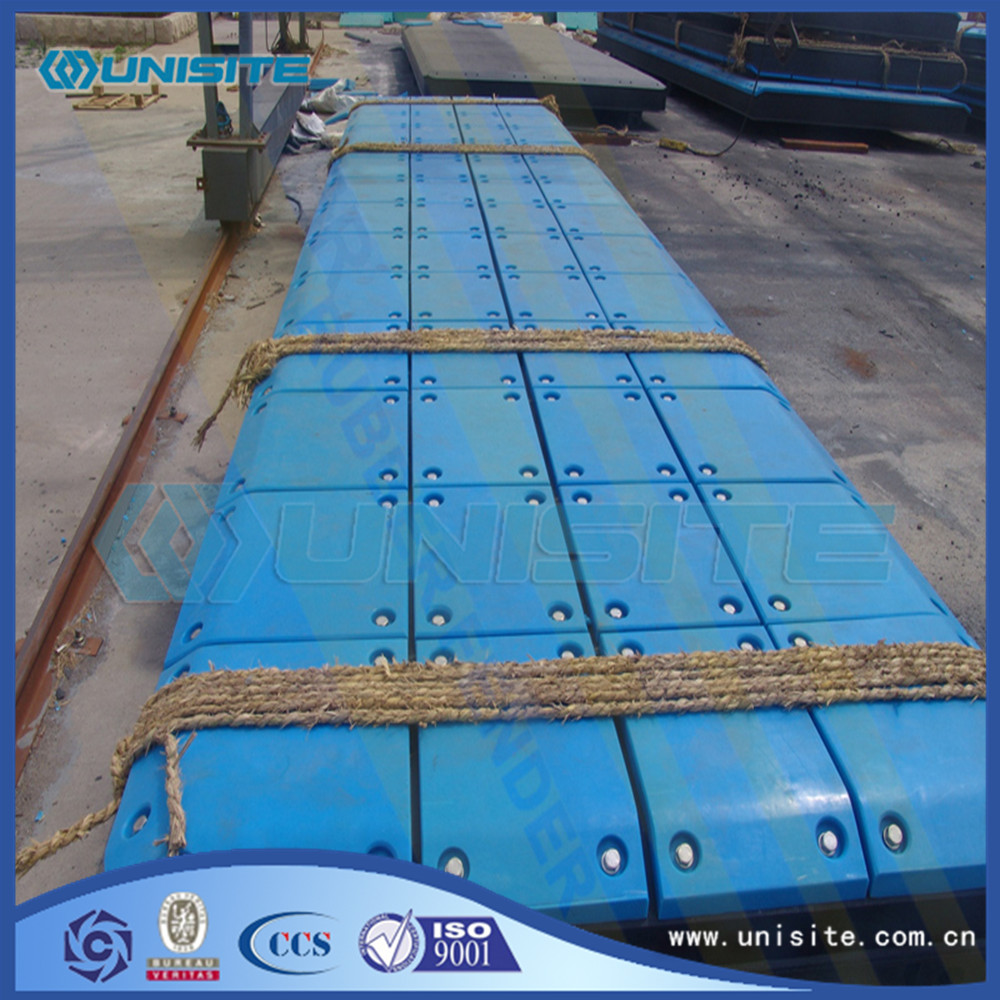

Photos of our High strength steel fender frames

Our service

Besides above the general specifications, we can also supply some specific Fender Frame and other similar steel structure as clients' requirements.

Package and shipping

bulk package and bulk vessel transportation

container package and container transportation

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Structures > Fender Frame