The fixed part of the trunnion Gantry is a closed steel construction, welded on deck. The portal frames support a guide frame, which remains vertical during movements of the gantry and guides the sliding piece with the trunnion elbow. A service frame carries measuring cables to the sliding piece and Suction Pipe.

Formal classification

Gantry crane can be according to the structure of the door frame, according to the main beam form, according to the main beam structure, according to the use of the form of classification.

Door frame structure

Door type crane and cantilever gantry crane

Portal crane

1. the whole gantry crane: the main beam without suspension, the car in the main span of the;

2. half gantry crane: the legs are high or low, can be used in accordance with the requirements of the use of the site.

Cantilever gantry crane

1. double cantilever gantry crane: the most common form of structure, the structure of the force and the effective use of the site area are reasonable.

2. single cantilever gantry crane: the structure of the form is often due to the restrictions of the site was chosen.

Production and equipment

UniSite knows the importance of advanced technology, equipment, quality and continuously invests in advanced equipment.

Equipment list:

pipeline production equipment

machining equipment

welding equipment

bending press equipment

rolling equipment

shears equipment

CNC plasma cutting equipment

advanced paint room and equipment

auxiliary equipment

Technology

Offering our client best possible and most sustainable solutions to their requirement. Production procedure:

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Other procedure if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Machining if necessary;

Step7: Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step8: Package, Loading and Lashing when delivery;

Quality management

UniSite have a perfect managing system and quality control system which from initial work.

ISO9001-2008/CCS; BV manufacturer capability qualification.

Taken part in the CHINA DREDGING ASSOCIATION

Quality, health, safety and environment (QHSE)

Production guidelines

In-house safety training to our staff

Checking all the production equipment periodically

Preventing pollution, accidents and health hazards, auditing

The group has a perfect managing system and our staff who are professional in technology are committed, passionate, efficient.

Thanks to the knowledge, the experience and the skills of our work team, we are able to offer our client best possible and most sustainable solutions to their requirement.

We are one of the leading steel parts and service providers for dredging and marine engineering in China.

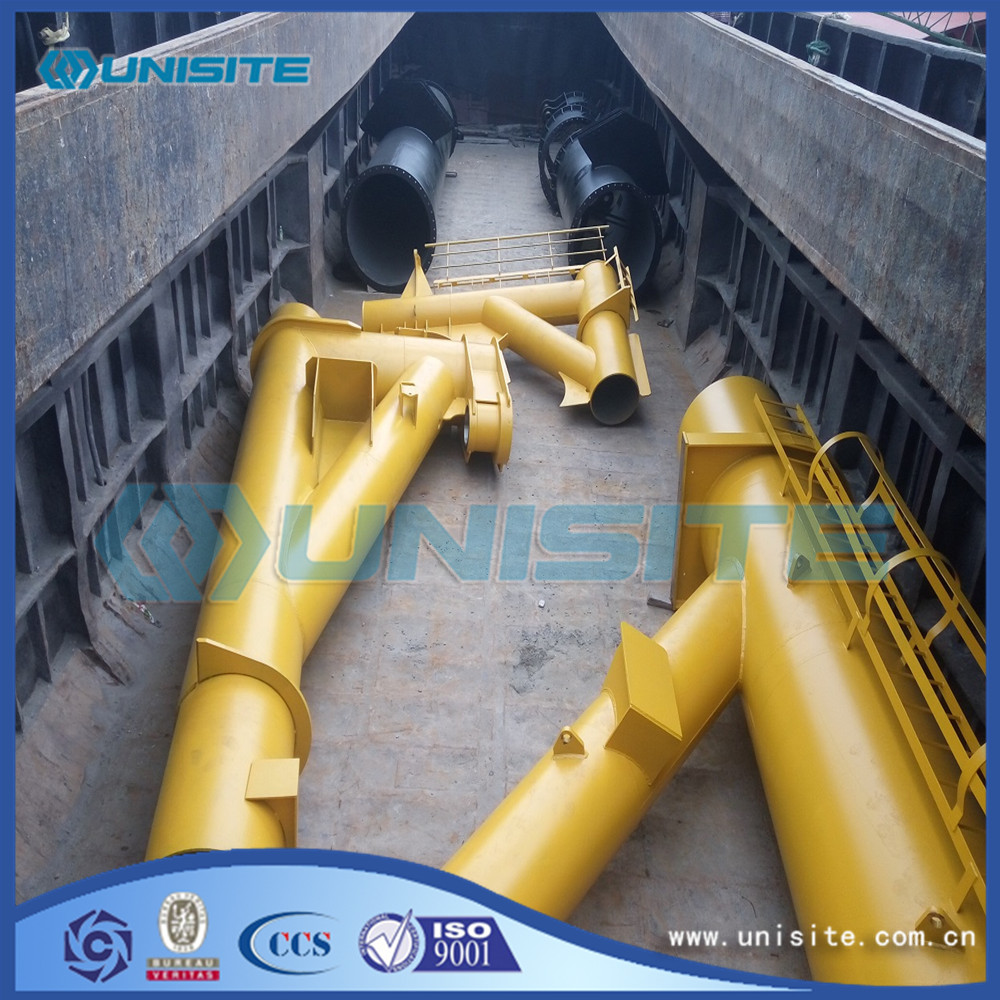

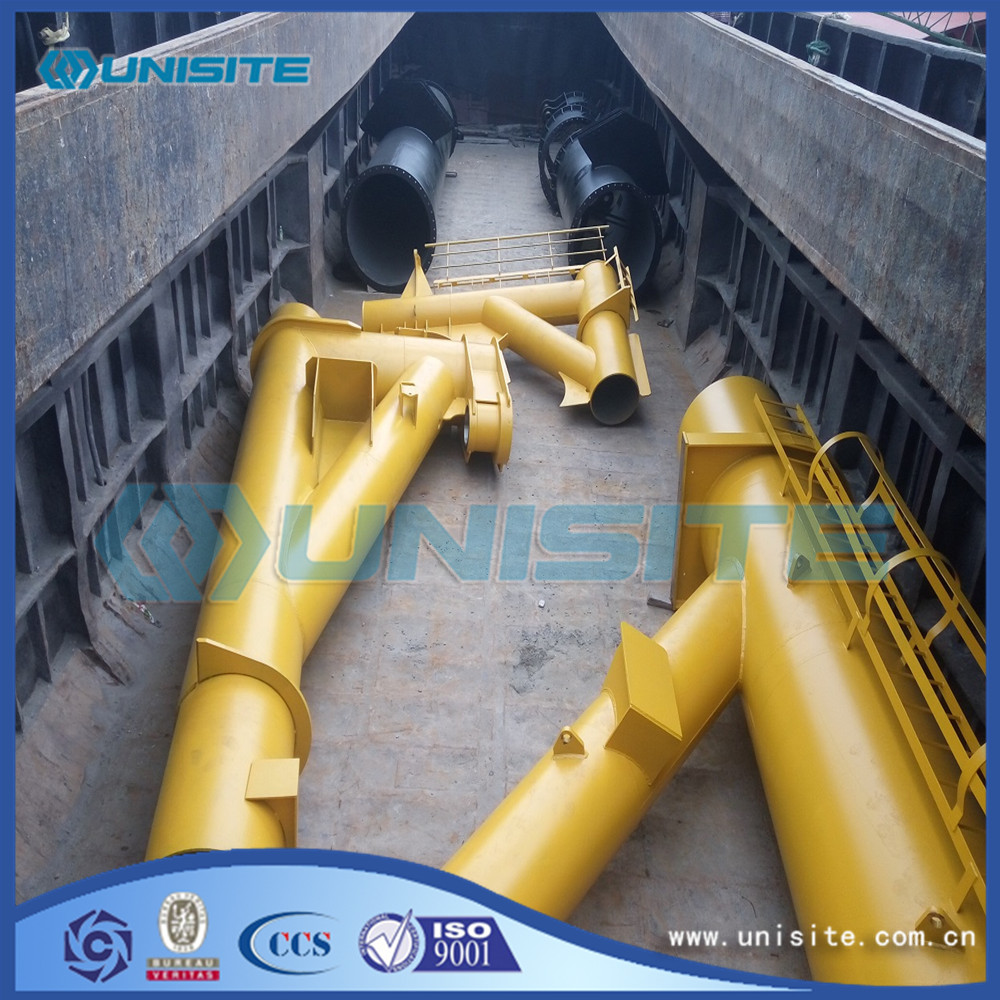

Photos of our Large steel gantry cranes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Structures > Gantry