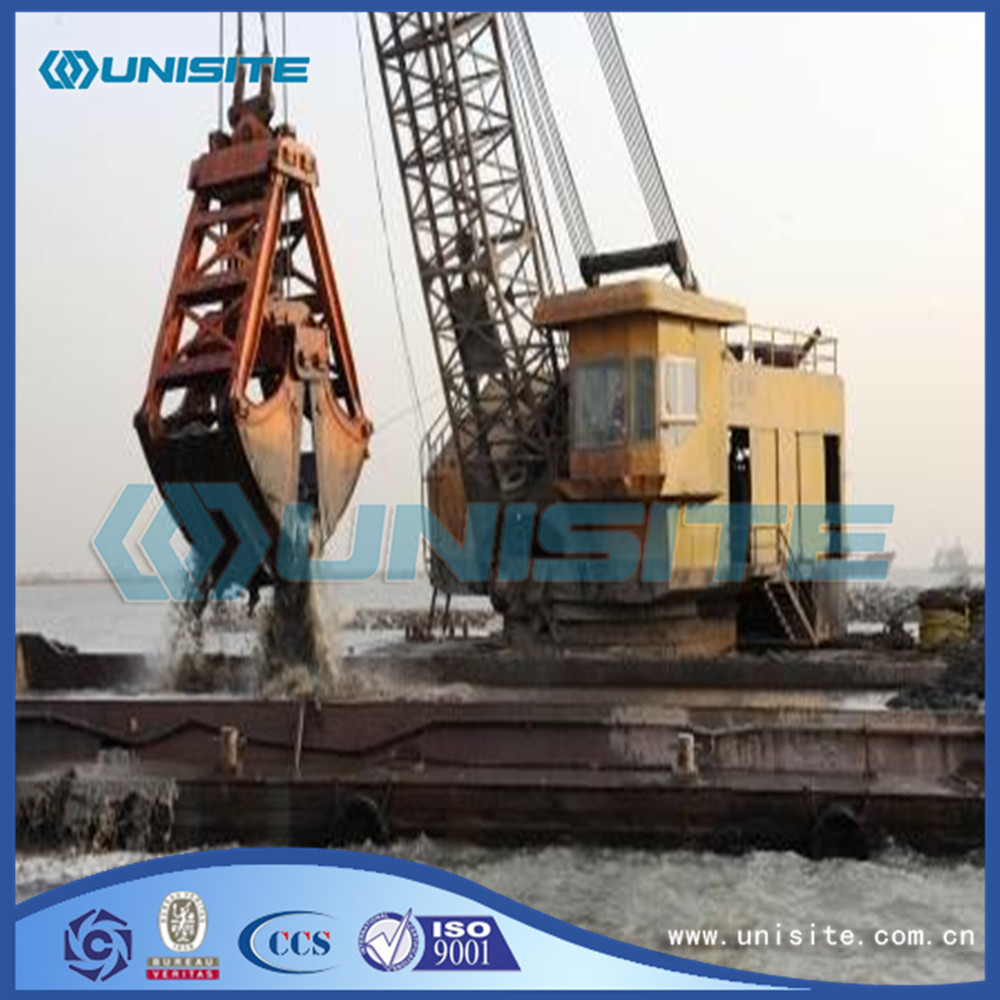

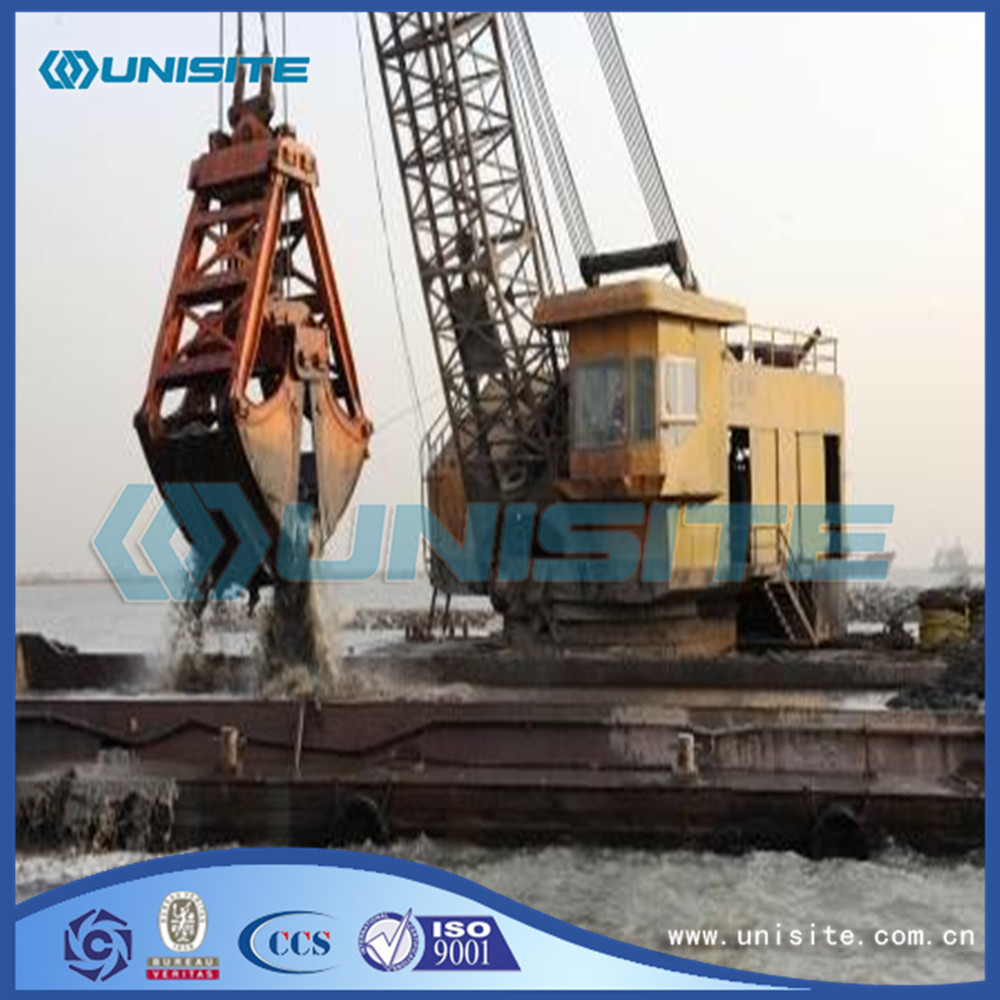

Grab Dredger divide into self-propelled and non self propelled . Self propelled generally hopper belt, mud tank filled from airlines to mud area dumping; non self propelled by mud Barge clay loading and unloading mud: use of wire rope Grab Dredger, relying on the action of gravity, into the water to a certain depth, by the insertion of a mud layer and a closed grab to mining and grab sediment, then through the manipulation of ship crane mechanical lifting grab out of the water, swing to a predetermined position the sediment discharge into the hopper or mud barge, and so forth. Grab dredger for waterway and harbor pool, and water infrastructure dredging work. Suitable for mining silt, gravel and clay, but it is not suitable for mining sand and silt.

Principle of grab dredgers

Dredging using wire rope grab, rely on the action of gravity, into the water to a certain depth, by the insertion of a mud layer and a closed grab to mining and grab sediment, then through the manipulation of ship crane mechanical lifting grab out of the water, swing to a predetermined position the sediment discharge into the hopper or mud barge, and so forth.

classification of grab dredgers

Grab dredger is self-propelled and non self propelled two. In general, the tank is filled with mud, and the mud tank is filled with dump mud from the air to the dump area.

Key points of construction technology control

Transverse excavation method construction

Grab dredger for horizontal excavation. Operation timed assigns 5 mooring, main anchor cable length should be 200 to 300 meters, the anchor tail length should be 200 to 300 meters, high velocity of poor quality long timely. The edge should be thrown in mooring line outside the 100 meters. Near point positioning, anchored procedures and chain bucket ship basically the same.

The concurrent and countercurrent construction

Grab dredger should adopt concurrent construction. When the flow rate is not large or there is a reciprocating flow, it can be used as a counter current.

Working method of the grab dredger

For clamshell dredgers the method of anchoring and the positioning system plays an important role for the effectiveness of the dredger. The volume to be dredged at a position decreases with the angle from the centerline. So dredging areas from -90° to +90 ° from the centerline is not always effective.

The dredging process is discontinuously and cyclic.

• Lowering of the grab to the bottom

• Closing of the grab by pulling the hoisting wire

• Hoisting starts when the bucket is complete closed

• Swinging to the barge or hopper

• Lowering the filled bucket into the barge or hopper

• Opening the bucket by releasing the closing wire.

Releasing the aft wires and pulling the fore wires does the movement of the pontoon. When the dredgers have spud poles, this movement is done by a spud operation, which is more accurate than executed by wires.

Certificates - Material certificates by a classification society - Inspection protocol - Inspection reports tank testing - NDT reports - Official certificates for accessories and other equipment - Fixed certificate: ISO9001, BV certificate, CCS certificate

Photos of our Steel marine grab dredgers

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Dredger > Grab Dredger