An Impeller is a rotating component of a centrifugal pump, usually made of iron, steel, bronze, brass, aluminium or plastic, which transfers energy from the motor that drives the pump to the fluid being pumped by accelerating the fluid outwards from the center of rotation.

Centrifugal pump impeller mainly in the following 4 forms,( 57089952,a) closed; (b) the first half open; (c) half open; (d) open

1 - 2 - rear impeller;; 3 - 4 - wheel; the front cover; 5 impeller sealing ring; 6 stiffeners

Closed impeller

And before and after the cover is composed of blades. The efficiency of the closed impeller is higher, the manufacture is more difficult, and the centrifugal pump is the most widely used. Suitable for delivery of water, solution, such as the viscosity of the smaller particles of clean liquid.

Semi open impeller

Generally have two kinds of structure: first half open, is composed of a rear cover plate and blades, the structure, the efficiency of the impeller lower, in order to improve the efficiency to be matched with a seal ring which can adjust clearance; another half open, is composed of a front cover plate and blades. The application and closed the same impeller sealing ring, efficiency and closed impeller is basically the same as the blades, and in addition to transport liquid, also has back blade or vice impeller seal. The semi open impeller is suitable for conveying liquid containing solid particles, fibers, etc.. Semi open impeller manufacturing is difficult, low cost, and adaptability, in the oil refining and chemical industry with a gradual increase in the application of centrifugal pump, and for the transport of water and water approximation of the liquid.

Open impeller

Only blades and blades to strengthen the reinforcement, no front and back cover of the impeller (open impeller blade number less 2-5). Impeller efficiency is low, the application is less, mainly used for conveying high viscosity liquid, as well as slurry liquid.

Blade of centrifugal pump impeller is generally backward curved blade. There are two kinds of cylindrical and twisted, the application of twisted blades can reduce the load of the blade, and can improve the suction performance of centrifugal pump, improve the anti cavitation ability, but the manufacture is difficult, the cost is higher.

Centrifugal pump for oil refining and chemical industry requires impeller for casting or whole welding seam welding of the integral impeller. Special centrifugal pumps for chemical use in the manufacture of metal materials (such as iron and its alloys), which are used in the manufacture of poor performance, such as iron and its alloys. The geometric accuracy and surface finish of the welded impeller are superior to the casting impeller, which is beneficial to the improvement of the efficiency of the centrifugal pump.

Advantages of UniSite

1. No customer quality complaints for 10years

We have a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

You can see the quality of all our previous orders were guaranteed based on our good procedure and service.

2. Born from military factory, with rigorous team having rich experience of military marine products

We UniSite started as a small contractor of ship building works in military factory in Ningbo 10 years ago. After several years of accumulation, the team had owned a certain number of experienced managers, engineers, technicians and workers who have rich experience in military shipping building and have good marine practice.

3. Involved in many big projects all over the world

We have involved in many projects all over the world that we have ability to participate in big projects.

4. BV/CCS approval for manufacturer capability qualification

We passed the BV/CCS approval for manufacturer capability qualification for dredging & Dredger products.

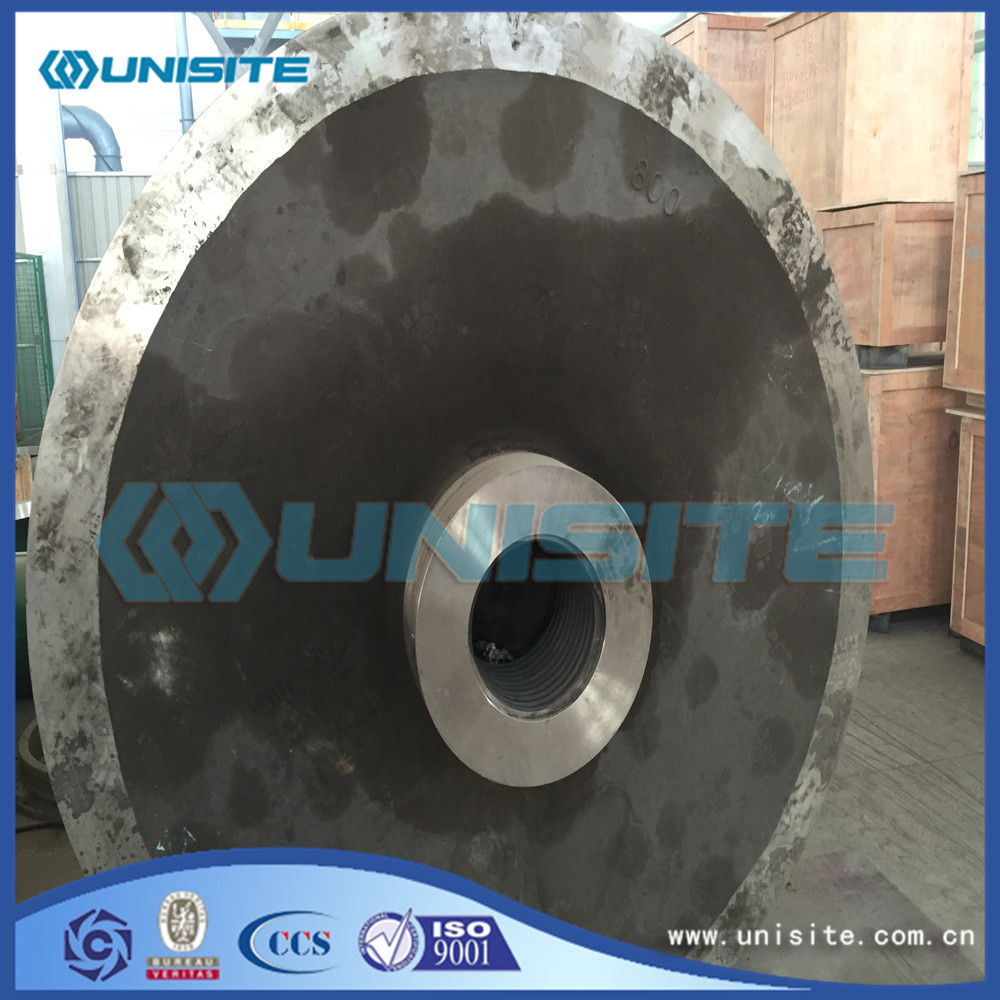

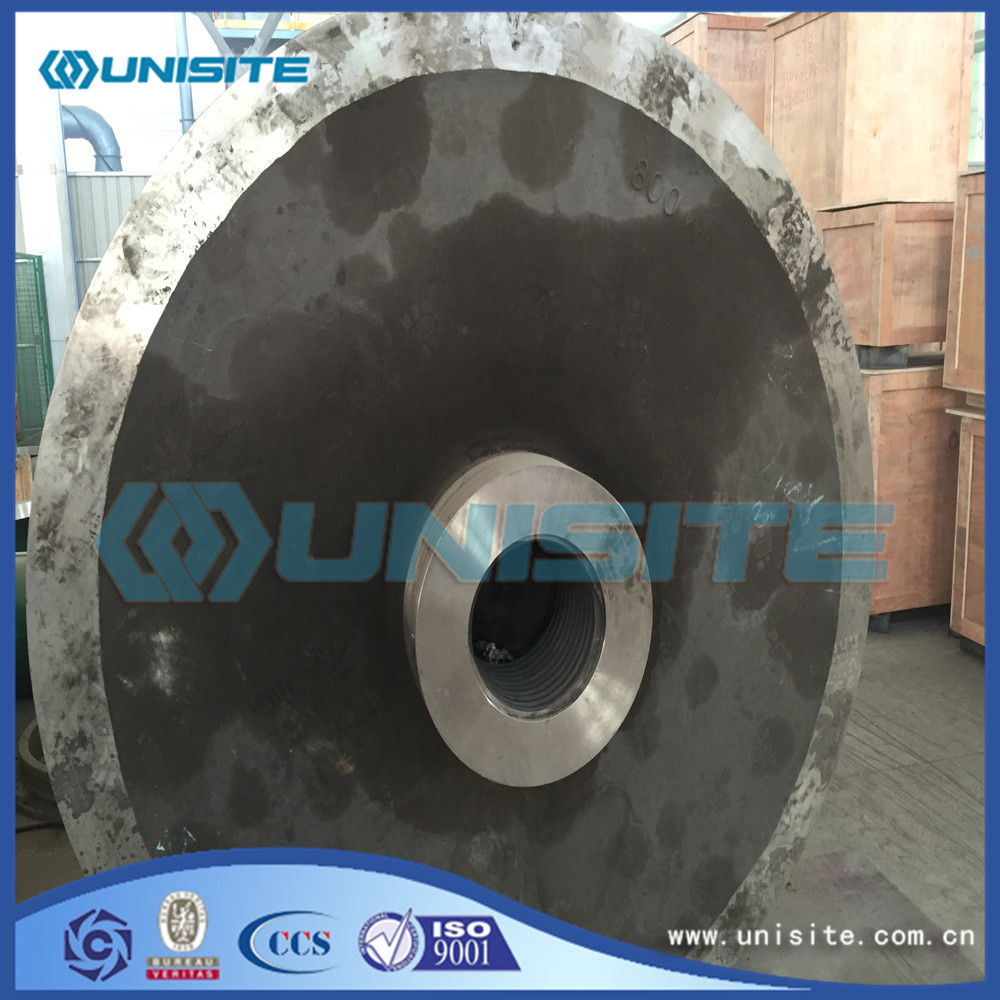

Photos of our Custom casting steel impeller price

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Pump And Spare Parts > Impeller