Dredger is a kind of high science and technology ship,and spud is the major structural part and throw away unit in the dredger.The design of spud is the key to design the dredger because of its complex force and high breakage rate. The spud is the most vulnerable structural member of the dredger, and the end of the position is inserted into the mud in the end of the working state. The other end is in the rear of the dredger, and the dredger is dredged round the spud.

A. General

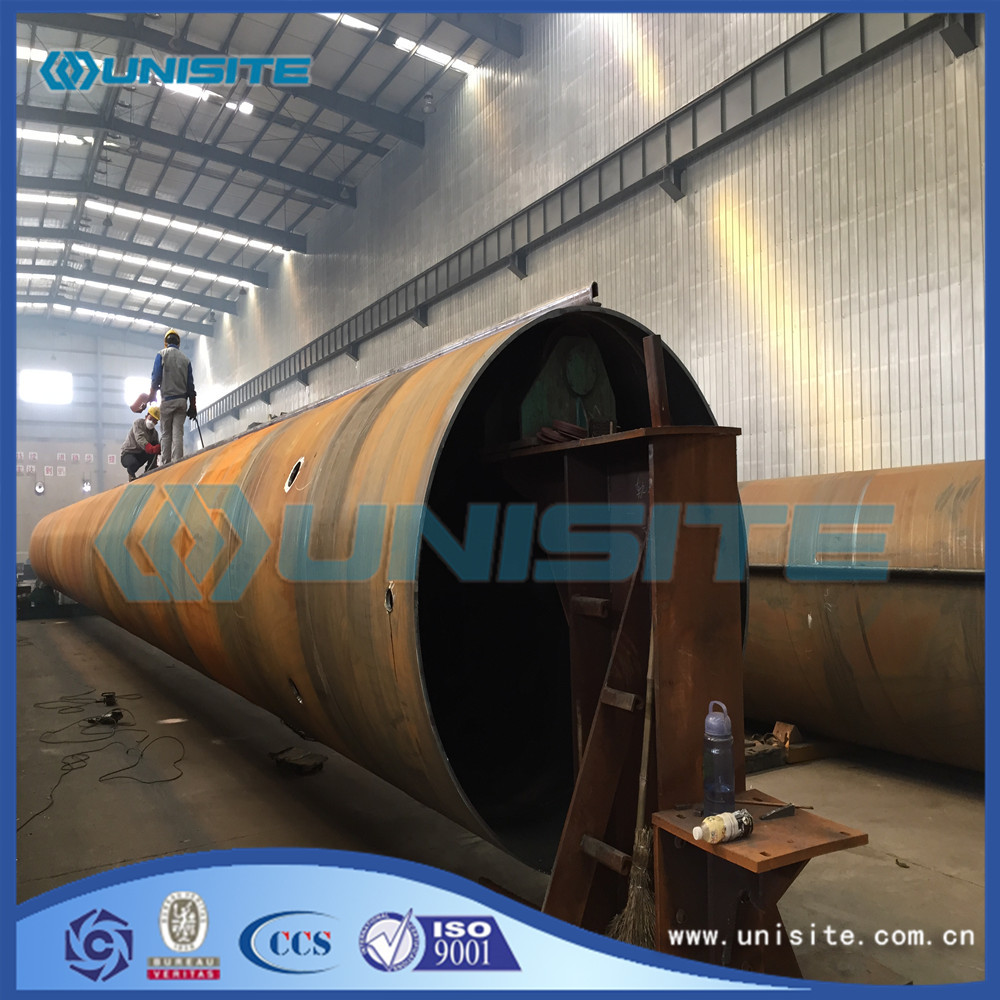

High accuracy, fully welded, painted construction can be used for Cutter Suction Dredger.

When the cutter suction dredger is working, two spuds insert the sea alternatively, one is main pile, always aligned pocket centerline and the other is vice pile used forward exchange, to meet dredger back and forth and meet dredging work.

B. Construction and procedure

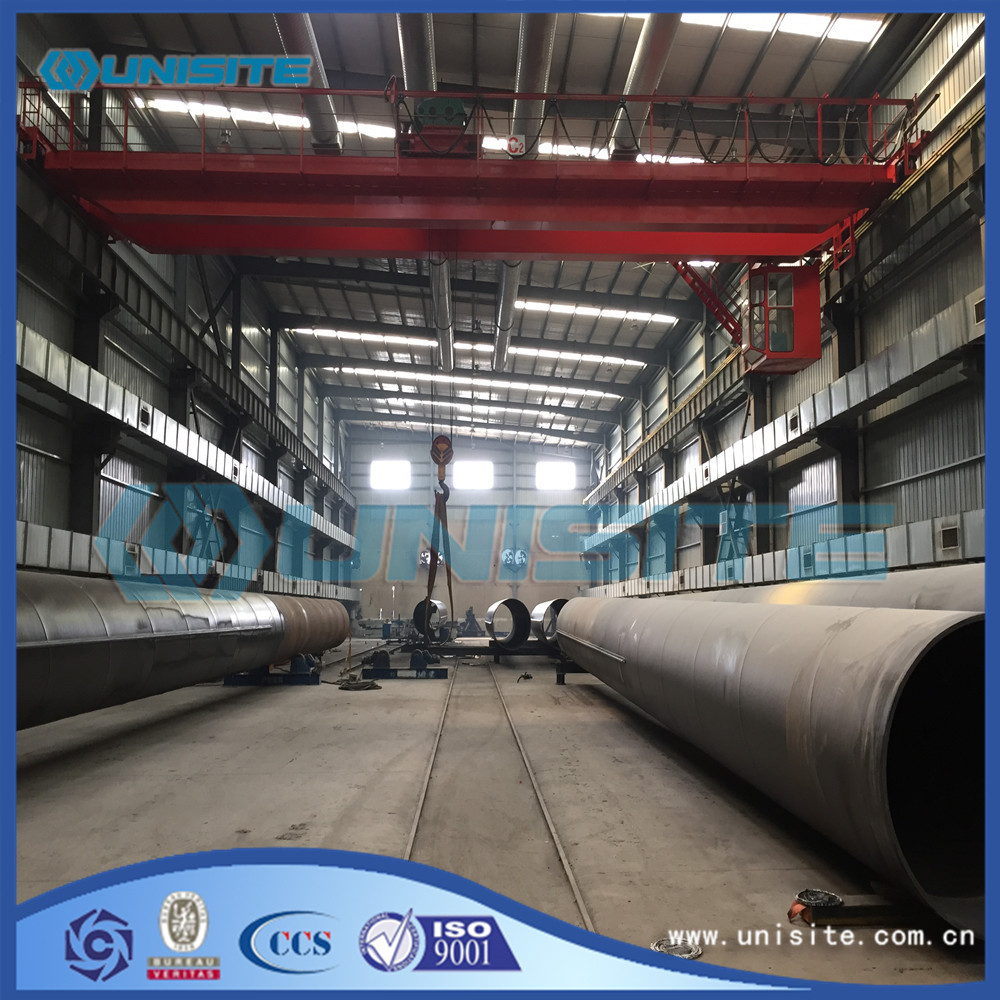

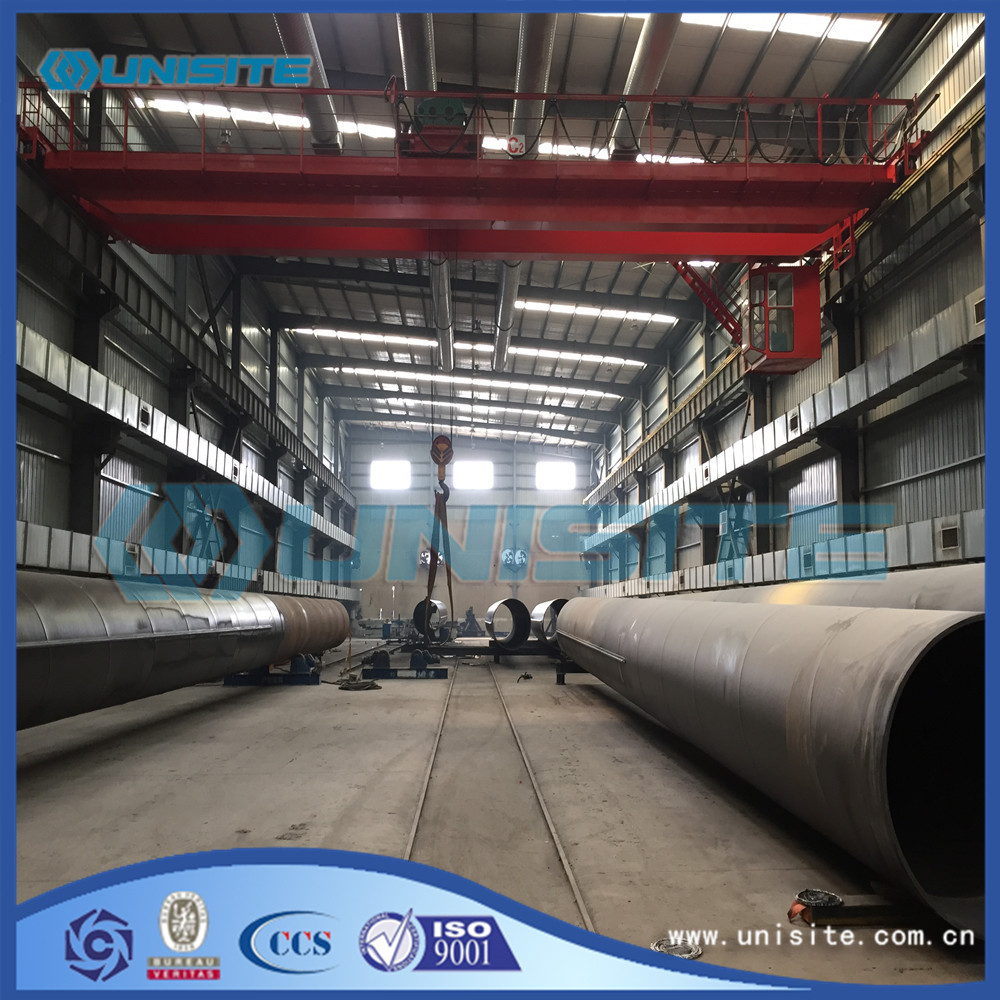

The construction is to be built according to the drawing with rules of good workmanship and to be built the longitudinal frame system.

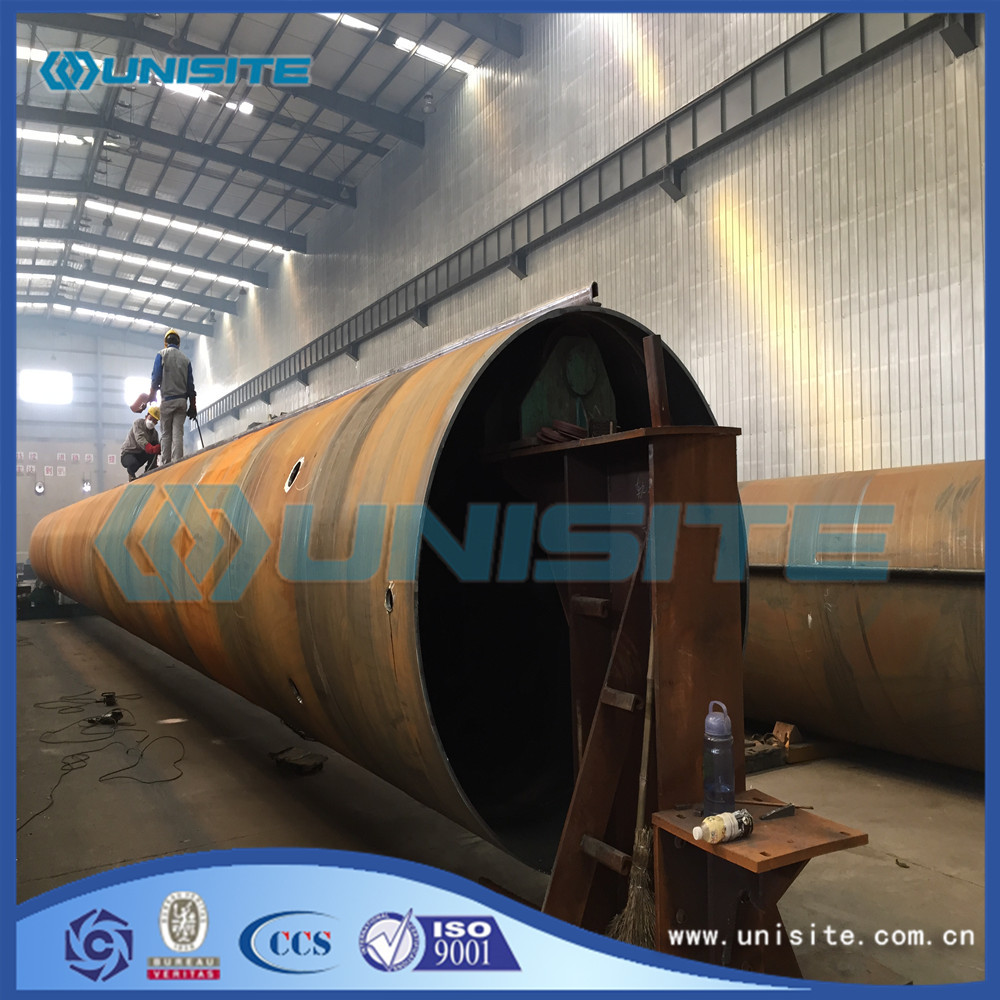

The construction is of rolled Steel Pipe sections with varying wall thickness, from40mm to 150mm, which are carefully manufactured and checked to ensure roundness, straightness, segment connection deflection within the specific tolerances.

C. Procedure

Pre-roll bending pf plate-Rolling of cylindrical hull-Welding the vertical seam to close the section-Heat treatment-Rolling to correct ovality-Assemble of the several pipe sections-Assemble with accessories(Sheave, expansion part etc.)

D. Materials

All fabricated steelwork used in the construction of the spud will be to manufacturing standard of classification society BV, GL, LR, DNV

All steel used to be blasted and shop primed both sides. Using DH36 and D690

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

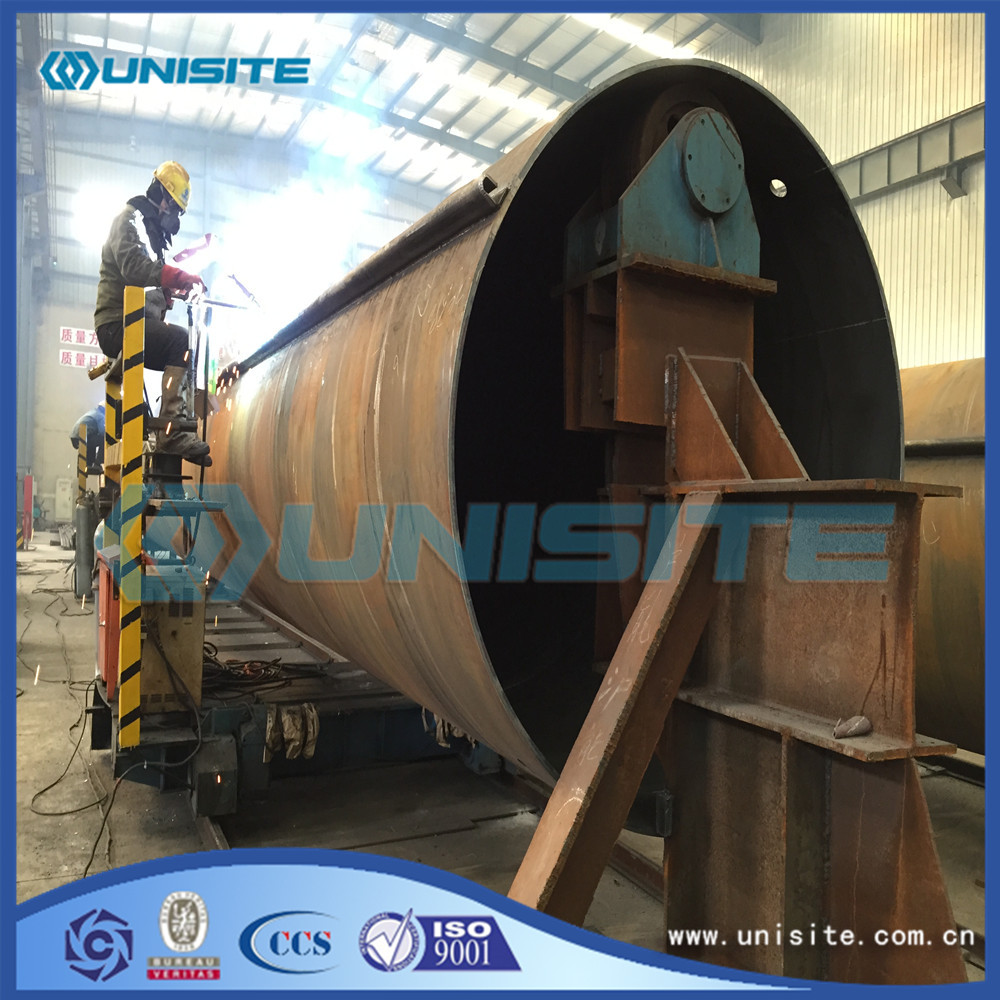

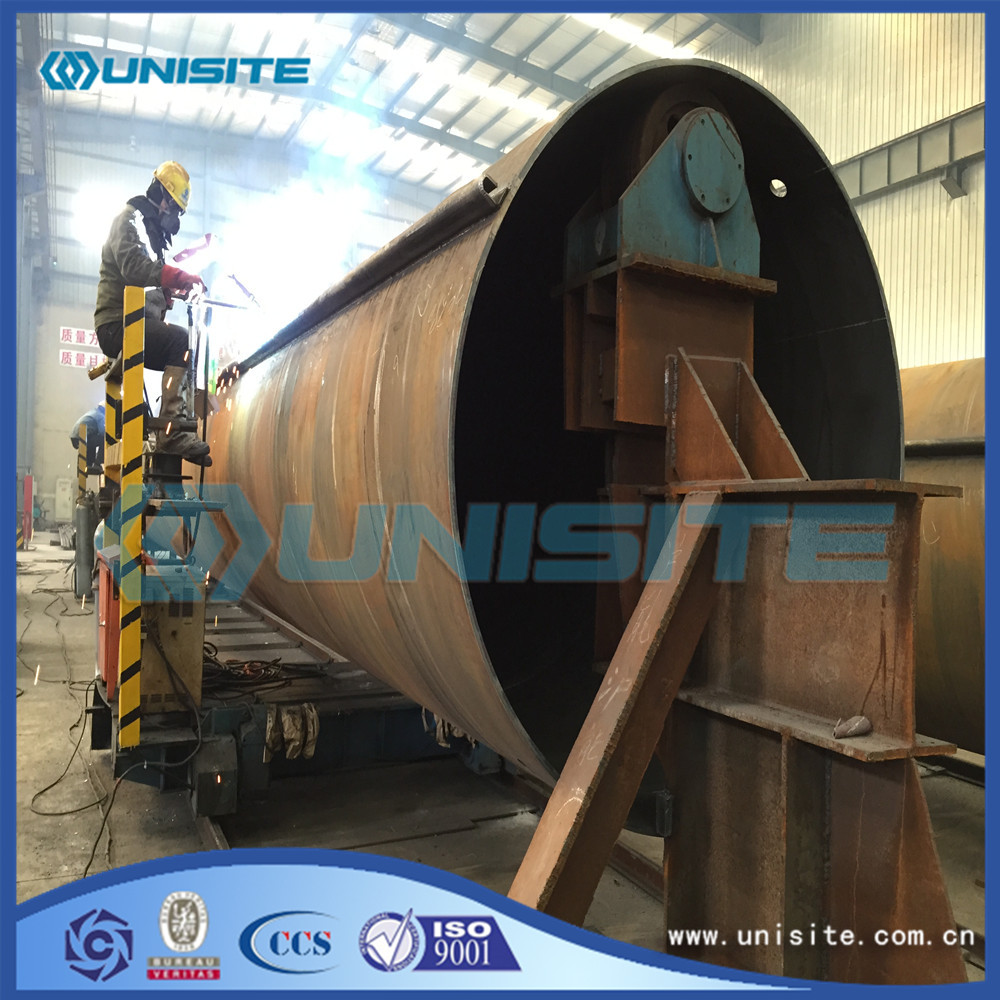

E. Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

Welding seam preparation, welding method, welding material and consequent preheating temperature acc. to UniSite standards and approved by clients.

UniSite will control preheating, cooling down rate

Weld surface on the outside spud surface are to be grinded flush.

All welding to be examined UT and some to be examined X-ray.

F. Workmanship

The workmanship have good marine practice. Care are taken to ensure fair lines, smooth surfaces and neat welding.

G. Main particulars

| | MAIN PARTICULARS |

| Tolerance | High accuracy(ISO2768, ISO5817, ISO13920) |

| Material | DH36, D690 with Z-quality or other materials |

| Dimension(L*B*H) | As per drawing, as large as we can |

| OD | 900mm-2800mm |

| Weight | 60Ton~400Ton |

| Coating | Sa2.5 blasted and two or three layers painted with highest quality |

| Marking | as per clients' requirements |

| Inspection | material, construction, dimension, welding seam, non defective test, paint inspection |

| Experience | We made OD2600*63m with total 360Ton spuds for world top dredging company. |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

H. Certificates

- Material certificates by a classification society EN10204 3.2

- WPS

- Inspection protocol

- NDT reports

- Official certificates for accessories and other equipment

- Fixed certificate: ISO9001, BV certificate, CCS certificate

Photos of Marine Steel Spud Pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Structural Pipes > Marine Spud