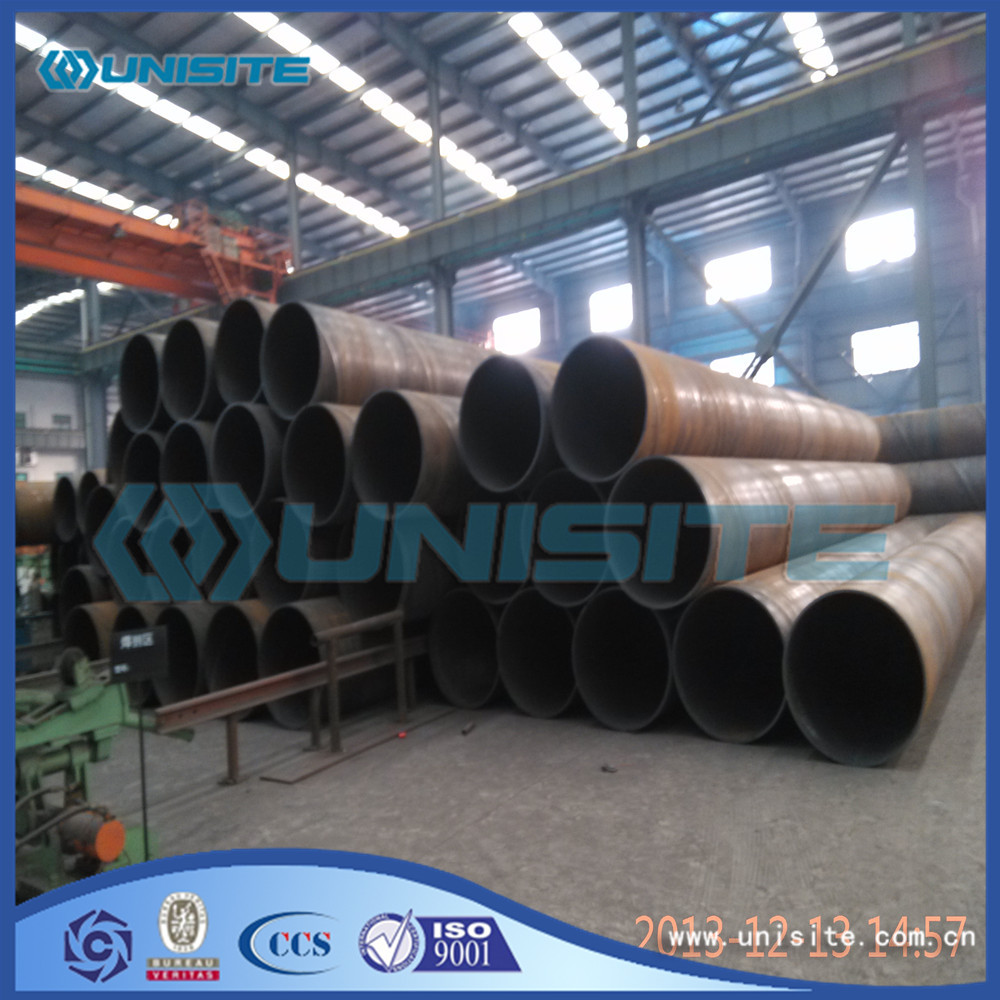

In recent years, the offshore deepwater wharf project in domestic coastal have also been large-scale construction, as a main bearing capacity of pile foundation deep-water wharf, generally used spiral seam of large diameter Steel Pipe piles [1];In addition, such as Bridges, roads, high-rise buildings are piling tube.

Manufacturing Method

Spiral steel pipe is a strip coil as raw material, often warm extrusion molding, automatic double wire double buried arc welding process of welding and the spiral seam pipe.

(1) raw material that is strip coil, welding wire, flux. Have to go through strict physical and chemical tests before they are put into the investment.

(2) strip head and tail docking, using single or double wire submerged arc welding, the steel tube rolled by automatic submerged arc welding welding.

(3) before molding, the strip passes through the leveling, trimming, planing, surface cleaning and conveying, and bending and handling.

(4) using the electric contact pressure gauge to control the pressure of the cylinder on both sides of the conveyor, to ensure the smooth delivery of the strip.

(5) the external control or internal control roll forming.

(6) using the welding gap control device to ensure that the weld gap to meet the requirements of welding, pipe diameter, the wrong side of the amount and the weld gap are strictly controlled.

(7) welding and welding with the Lincoln Electric welding machine for single or double wire submerged arc welding, so as to obtain the stable welding specification.

(8) the welding seam after welding is through the online continuous ultrasonic automatic inspection, to ensure that 100% of the spiral weld nondestructive testing coverage rate. If there are defects, automatic alarm and spraying marks, the production workers at any time to adjust the process parameters, timely elimination of defects.

(9) the air plasma cutting machine to cut a single pipe.

(10) into a single tube, each batch of steel tube head to strict inspection system first, check the weld mechanical properties, chemical composition, blending, surface quality of steel pipe and after nondestructive inspection, to ensure that the pipe manufacturing technology qualified, can be formally put into production.

(11) in the weld on the site of continuous acoustic inspection marks, after manual ultrasound and X ray review, if there are defects, after repair, once again after the non destructive testing, until the defects have been eliminated.

(12) strip butt weld and intersecting and spiral seam D connector tube, all through X ray TV or film examination.

(13) each pipe is tested by hydrostatic pressure, and the pressure is sealed by radial seal. The test pressure and time are strictly controlled by the steel pipe water pressure computer testing device. Automatic print record of test parameters.

(14) the pipe end machining, the end verticality, accurate control of slope angle and blunt edge.

Our products all over the world:

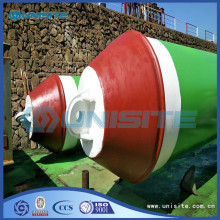

1. 2005 Palm island construction in Dubai: the large quantities of dredging pipeline including sink pipes, shore pipes with flanges and pontoons

2. 2005 Waterways dredging projects : the large quantities of pipeline, connected pontoons.

3. 2006 Waterways dredging projects: the large quantities of pipeline, connected pontoons.

4. 2007 Waterways dredging projects: the large quantities of pipeline, including sink pipes, shore pipes with flanges and pontoons.

5. 2008 Waterways dredging projects: the large quantities of pipeline, connected pontoons, floating pipelines and bends.

6. 2008 Capital dredging for a third berth at Anderson point in port Hedland in Australian: the large quantities of lsaw pipes

7. 2009 Waterways dredging projects: the large quantities of pipeline, connected pontoons and bends.

8. 2010 Environmental works:pontoon for work platform and pipes

......

and till now, above just a little projects we involved in.

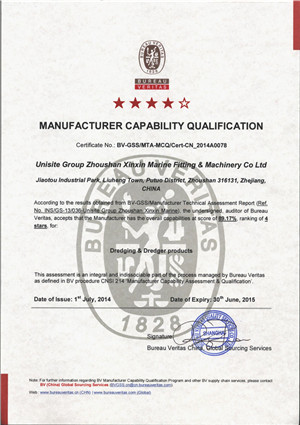

Certificates

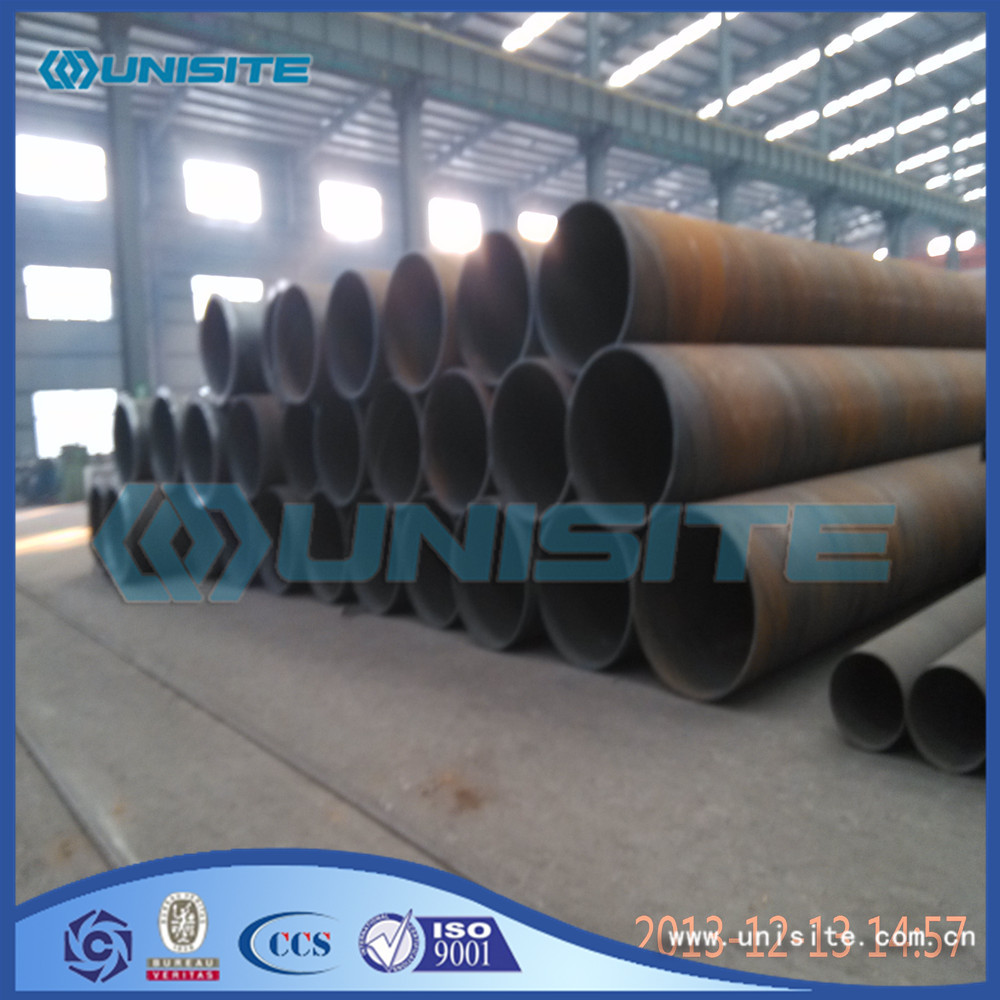

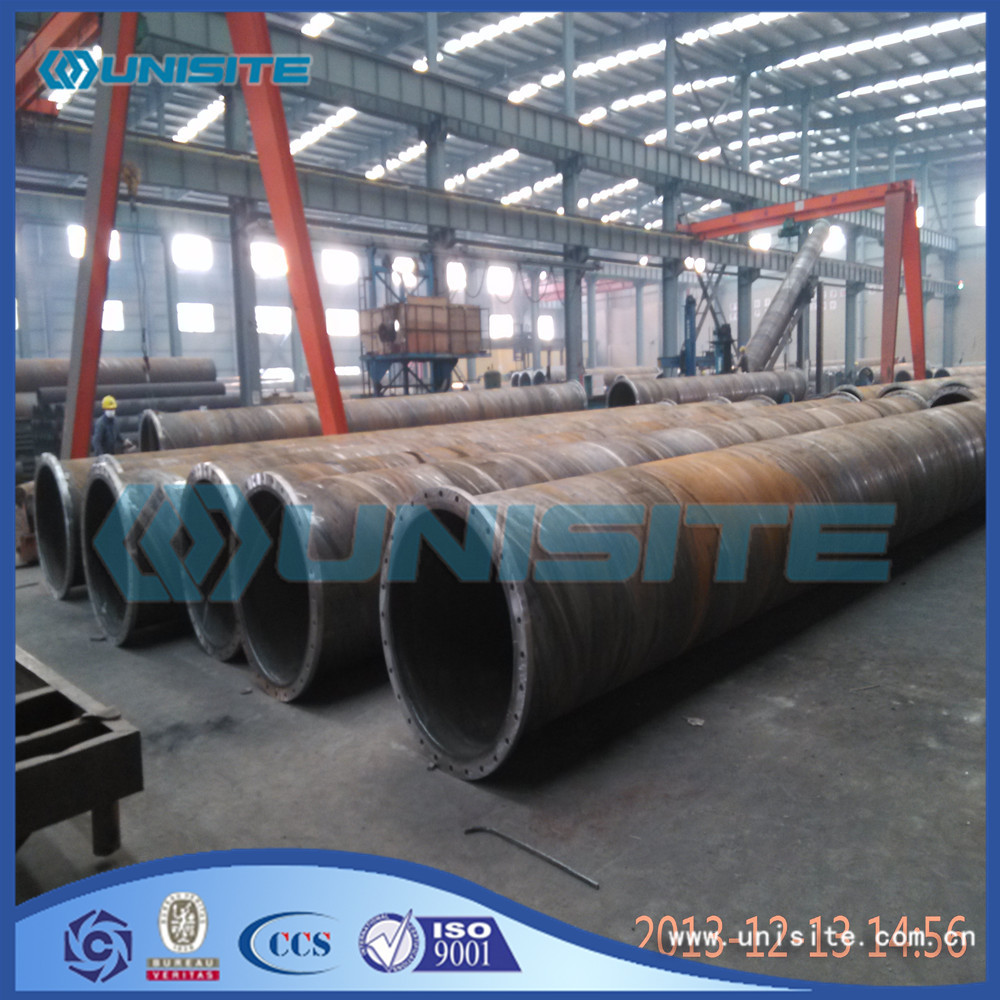

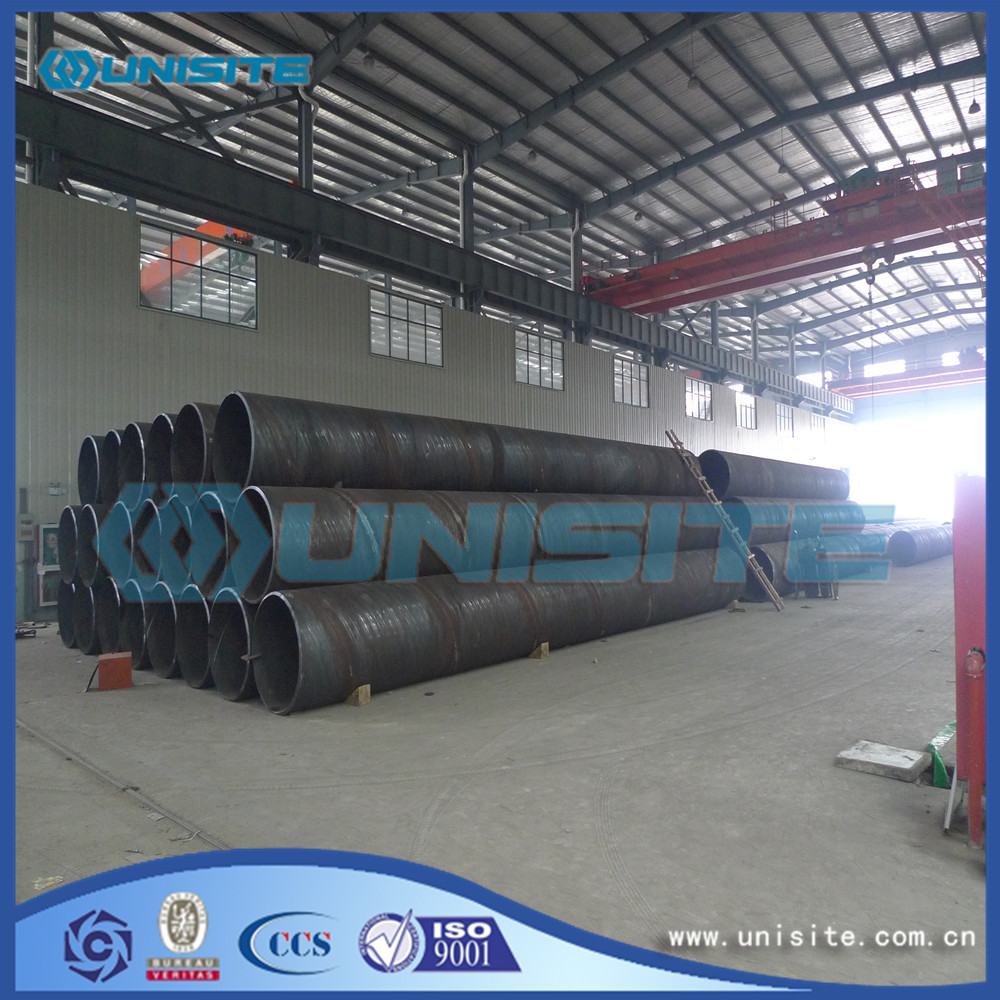

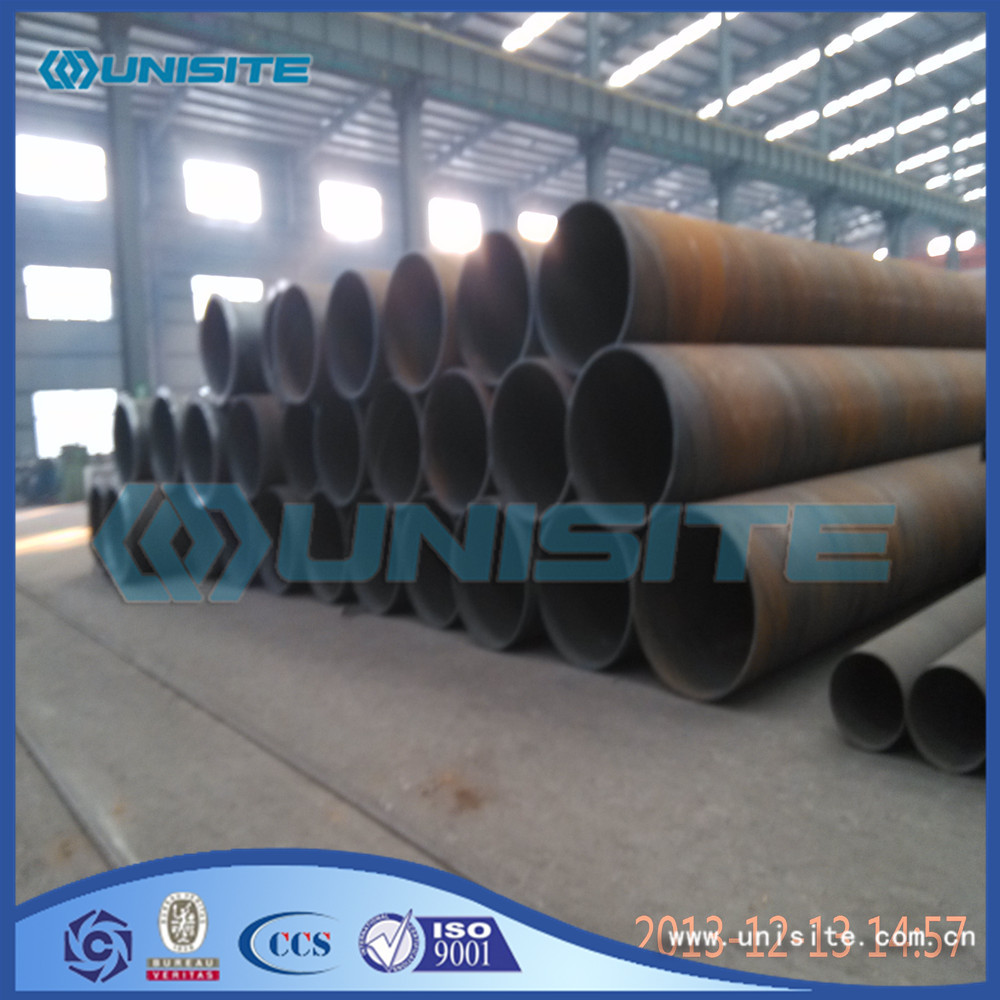

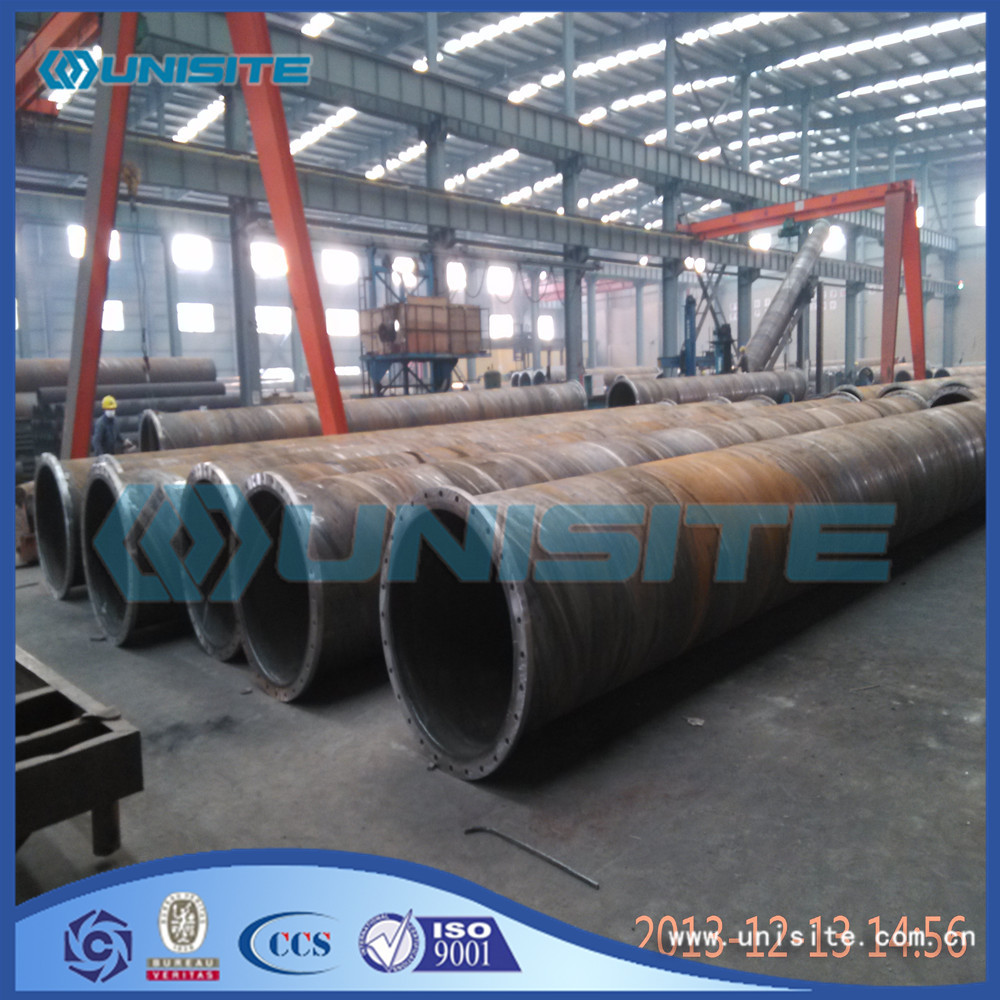

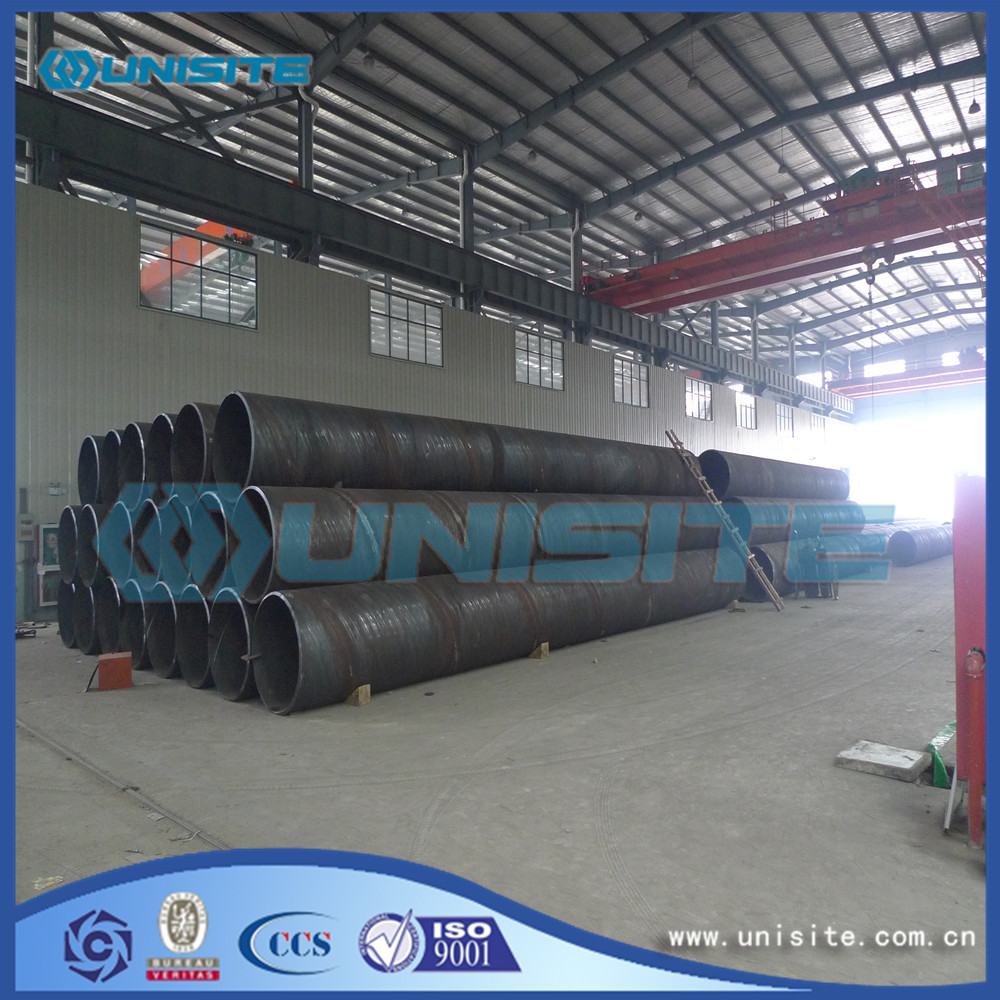

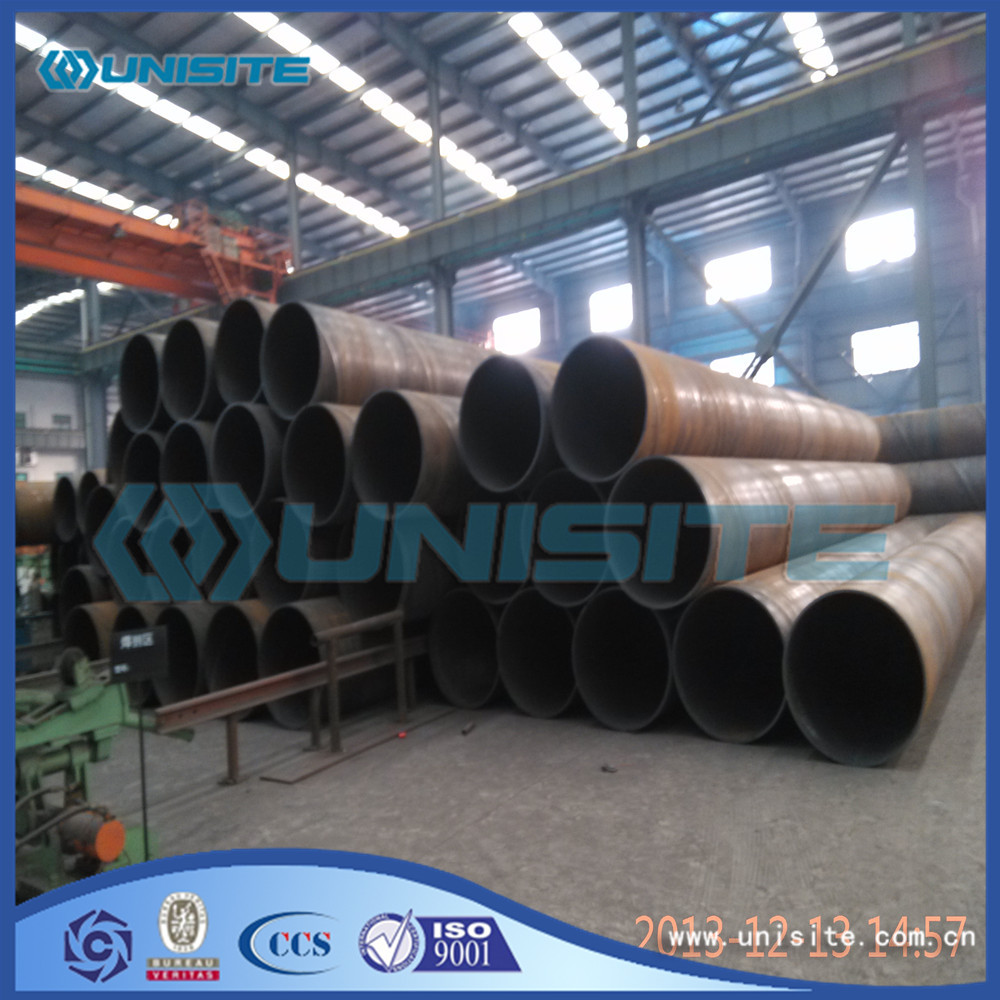

Photos of our Customized piling steel pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Piling Pipe