Bimetallic liner is the most widely used, dosage is one of the biggest Slurry Pump hydraulic fitting. Bimetallic liner is a combination of hot forging high wear coat and the advantages of high chrome wear-resisting corrosion inner sleeve coat is made of quality carbon steel hot-pressing time forming, sets of high chromium cast iron in centrifugal casting, the tensile strength of the coat has a higher than 900000 psi, inner sleeve after heat treatment, hardness greater than HRC62 can bear the mud pressure of 7000 psi, its surface smooth as a mirror, the inner hole size tolerance strictly, the normal service life of up to 800 hours.

Mud pump liner matters that should be paid attention to when using

Mud pump cylinder liner should be paid attention to when buying things

At the time of purchase slurry pump cylinder liner, first check the standard cylinder liner of standard size and figure number, with the cylinder must be same as the size of the standard cylinder liner grouping code, only in this way can ensure a standard fit clearance.

Mud pump cylinder liner installation matters that should be paid attention to when using

First: it is strictly prohibited to throw, throw, hit the mud pump cylinder liner, if you want to put down jacket, need to slowly.

Second: the need to ensure that mud pump piston when installation of metal parts and mud pump cylinder liner inner eccentric wear phenomenon does not occur as far as possible, if has the eccentric wear phenomenon, should be corrected as soon as possible.

Third: it is strictly prohibited such as heavy hammer struck the liner directly, must be paid when knocking on wood materials, such as slight tapping with a cushion.

Fourth: equipment under 0℃ in winter when stopped for a long time, should put off inhaling indoor mud, prevent mud crack freezing up mud pump cylinder liner.

Production equipment

UniSite continuously develops the whole production equipments including pipeline production equipments, machining equipments, material inspection equipments, welding equipments, bending press equipments, rolling equipments, cutting equipments which can be played maximum role in each project and service.

Photos of our workman

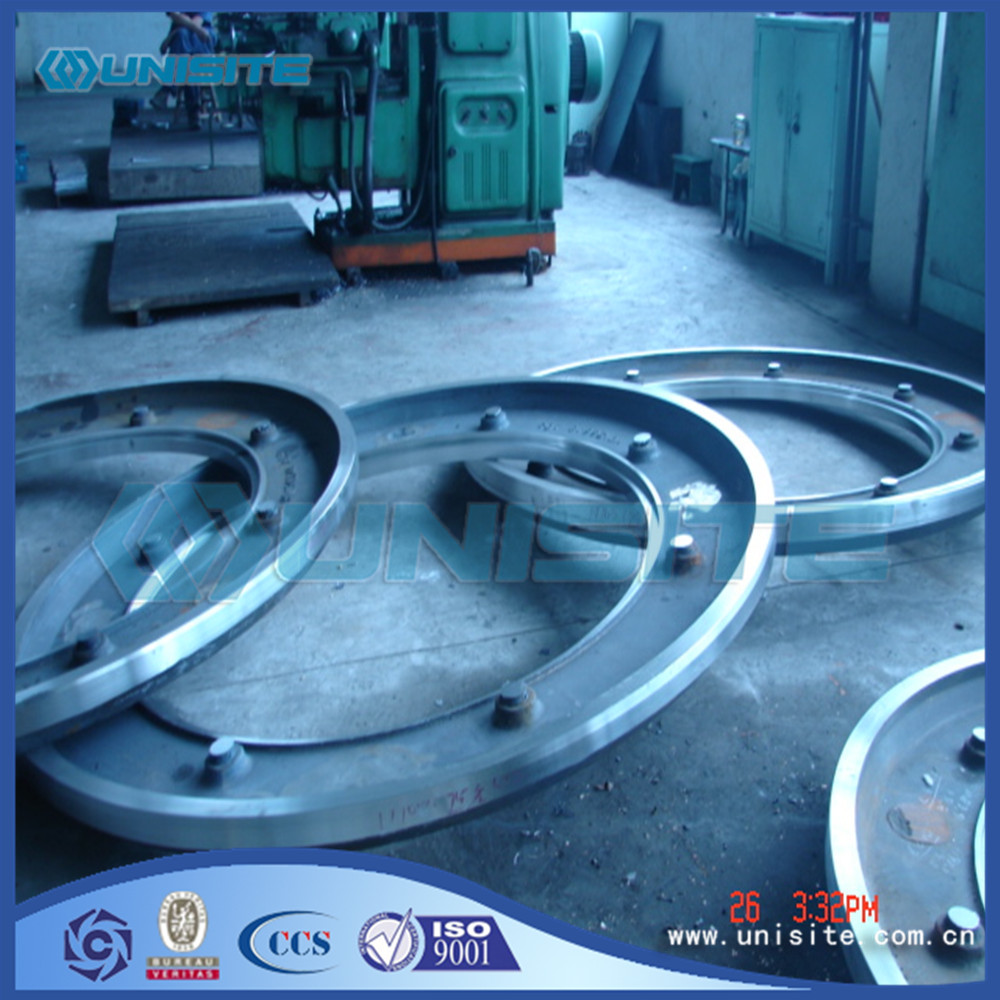

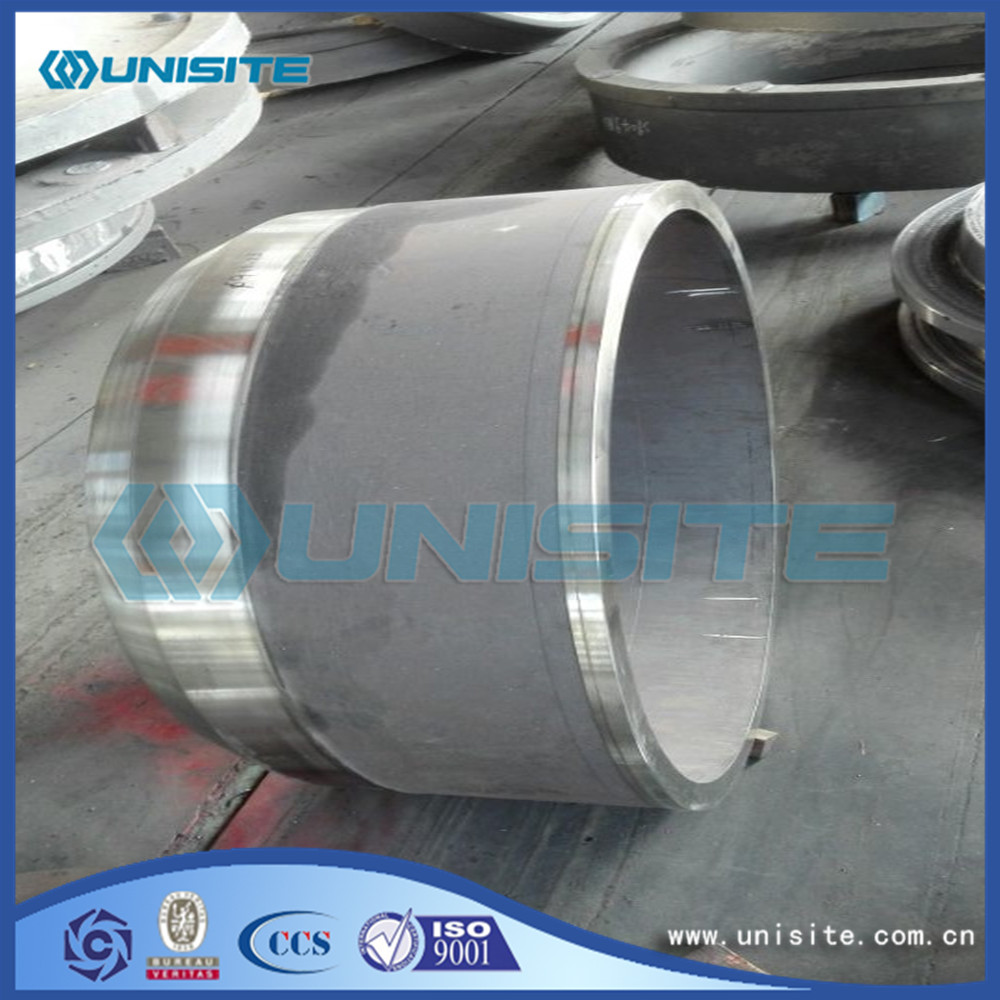

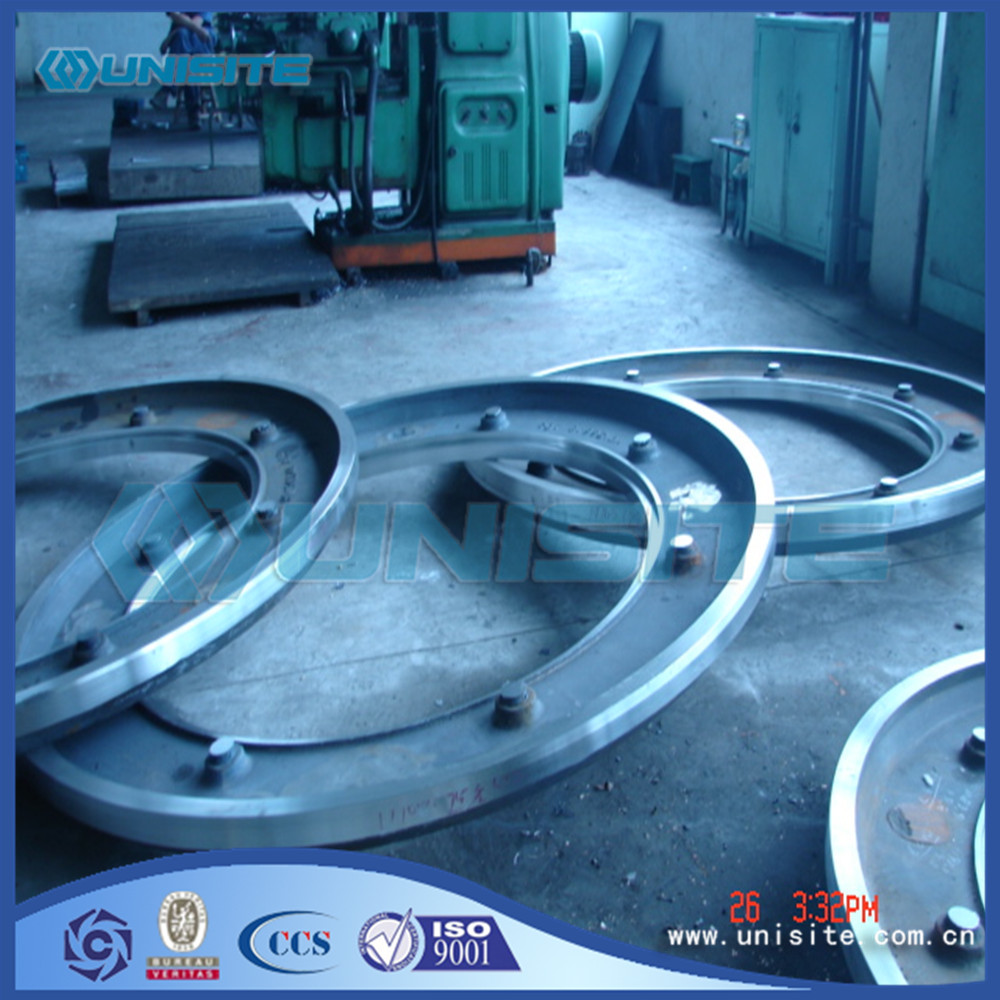

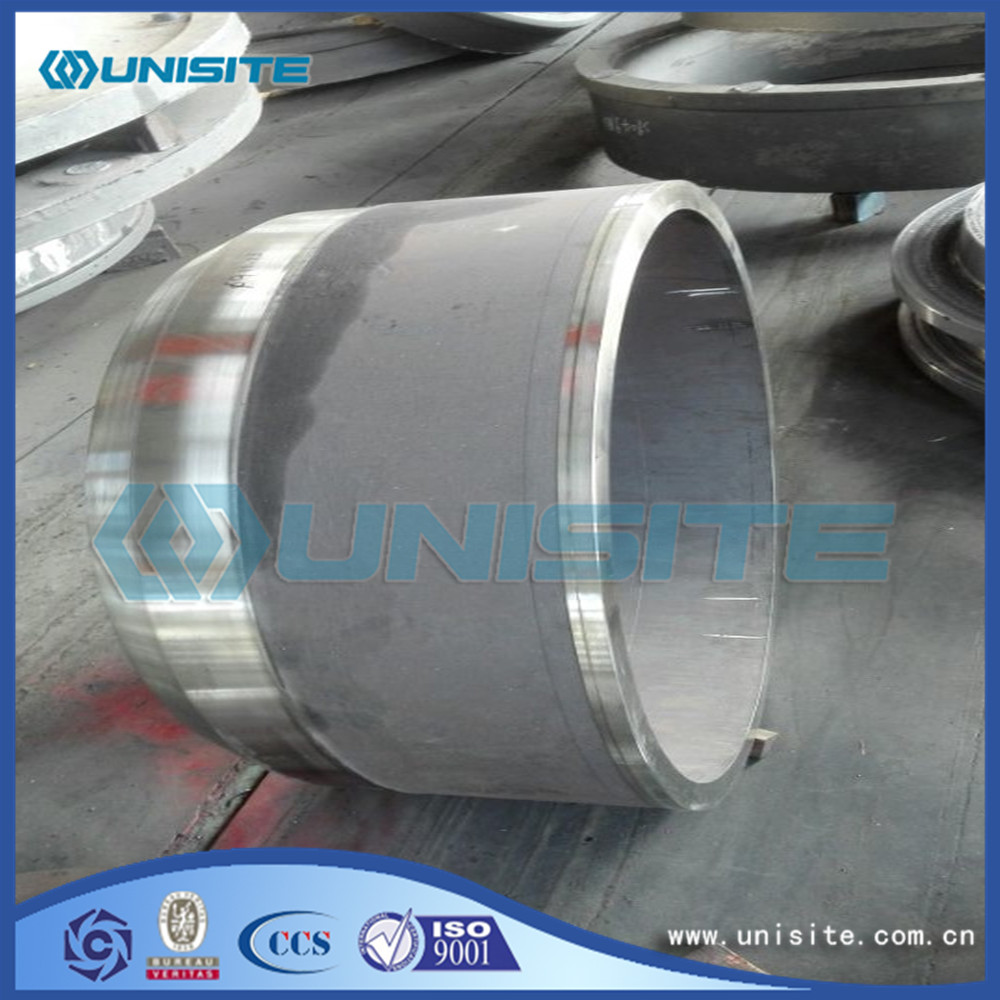

Photos of our Customized Casting Pump liner

Our products all over the world:

1. 2005 Palm island construction in Dubai: the large quantities of dredging pipeline including sink pipes, shore pipes with flanges and pontoons

2. 2005 Waterways dredging projects : the large quantities of pipeline, connected pontoons.

3. 2006 Waterways dredging projects: the large quantities of pipeline, connected pontoons.

4. 2007 Waterways dredging projects: the large quantities of pipeline, including sink pipes, shore pipes with flanges and pontoons.

5. 2008 Waterways dredging projects: the large quantities of pipeline, connected pontoons, floating pipelines and bends.

6. 2008 Capital dredging for a third berth at Anderson point in port Hedland in Australian: the large quantities of lsaw pipes

7. 2009 Waterways dredging projects: the large quantities of pipeline, connected pontoons and bends.

8. 2010 Environmental works:pontoon for work platform and pipes

......

and till now, above just a little projects we involved in.

Equipments:

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Pump And Spare Parts > Pump Liner