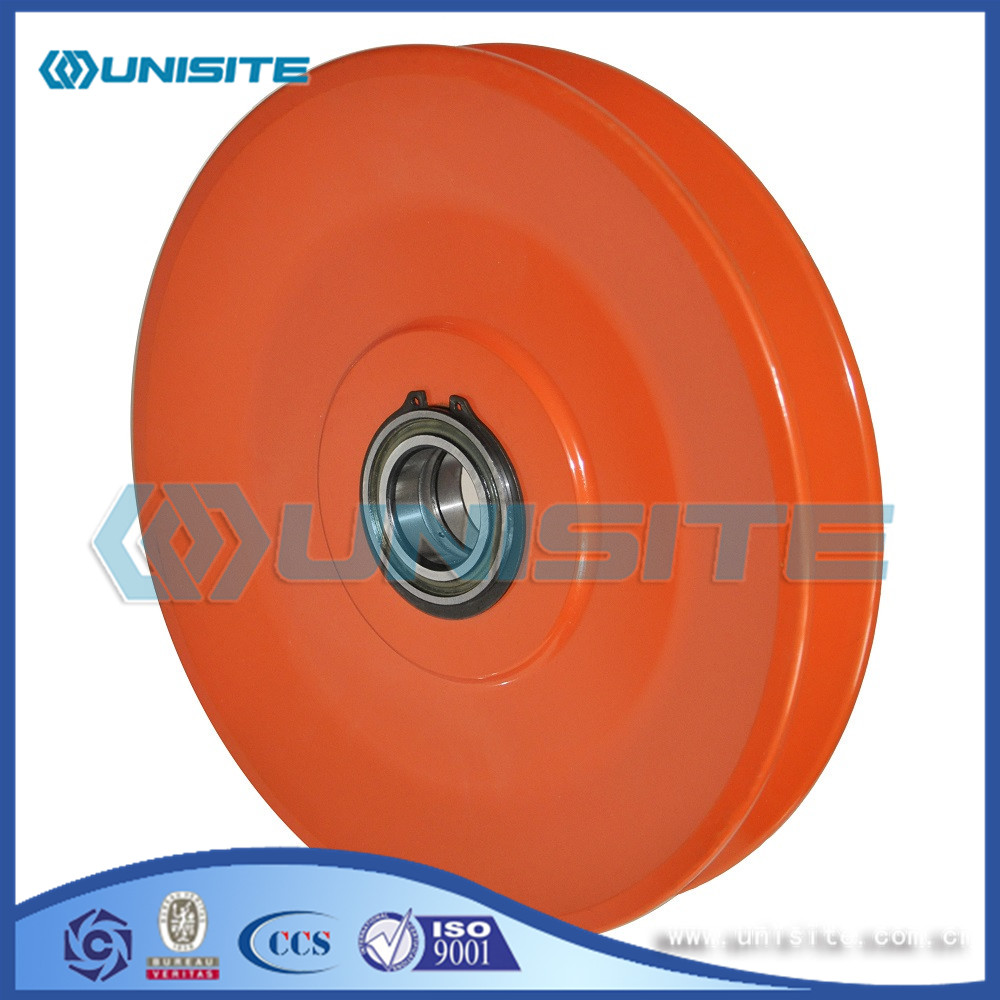

A Sheave can also refer to a pulley which has an adjustable operating diameter for use with a mechanical belt. This is accomplished by constructing the pulley out of several pieces. The two main "halves" of the pulley can be moved closer together or farther apart, thus altering the operational diameter. The usual construction is some sort of locking collar or set screws to secure the components, one half with a threaded central shaft and one half with a threaded center. By rotating the components one can "screw" the parts closer together or further apart, thus changing the distance between the two halves and allowing the belt to ride higher or lower in the groove. The adjustments are constrained to a specific range of size and are not limitless. One application of this is the Variomatic automatic transmission.

About quality control

Whether we are able to offer our client best possible and most sustainable solutions to their requirement or to complete our mission, our safety & quality are the key factors. So that quality, health, safety and environment (QHSE) on site are given priority which includes setting our QHSE standards and production guidelines, in-house safety training to our staff, checking all the production equipments periodically, preventing pollution, accidents and health hazards, auditing and verifying whether our work is being executed according our certified system ISO 9001, CCS certificate, BV certificate.

We a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

We also organize site short meetings (SSM) when new productions and activities are being under taken and when working plans, technologies, qualities and methods are altered.

Thanks to these efforts and activities, we are able to perform our best works in an efficient way.

Technology

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Other procedure if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Machining if necessary;

Step7: Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step8: Package, Loading and Lashing when delivery;

Our Services

Besides above the general specifications, we can also supply some specific pontoons and other similar steel structure as clients' requirements.

Packaging & Shipping

bulk package and bulk vessel transportation

frame container package and frame container transportation

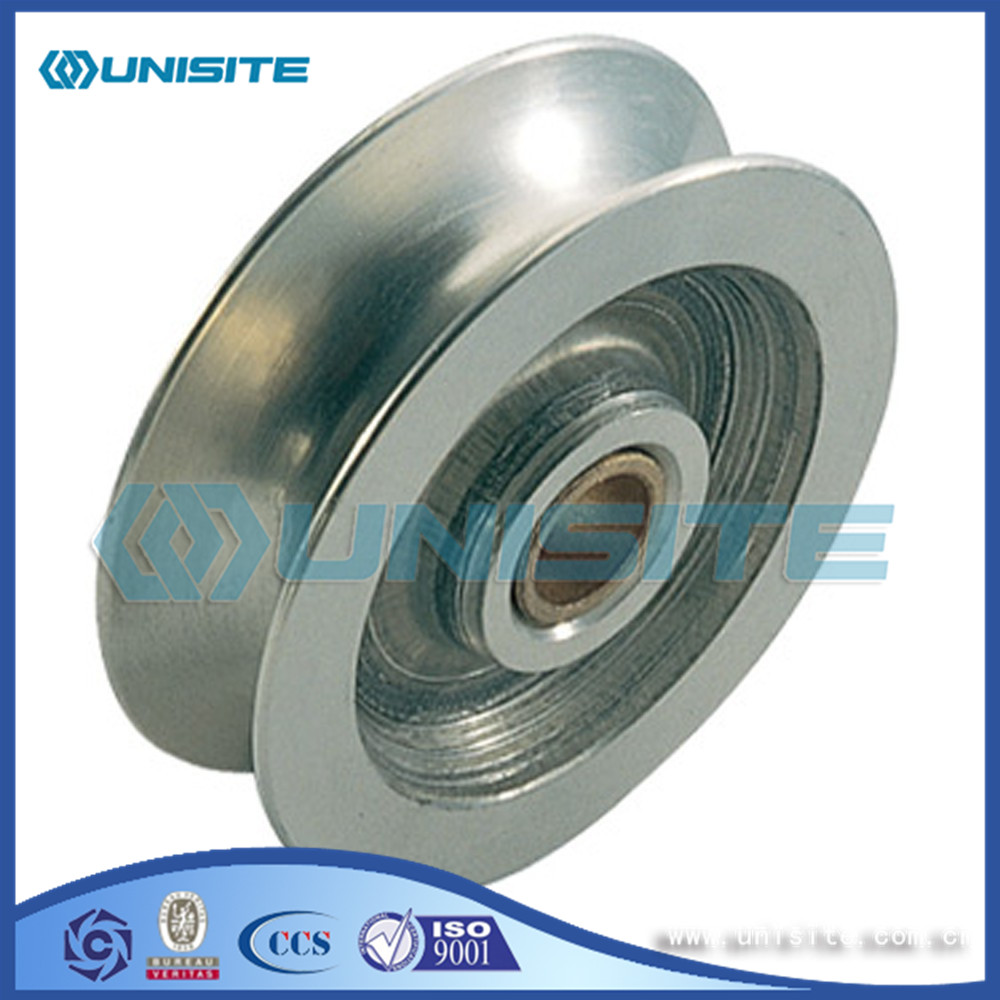

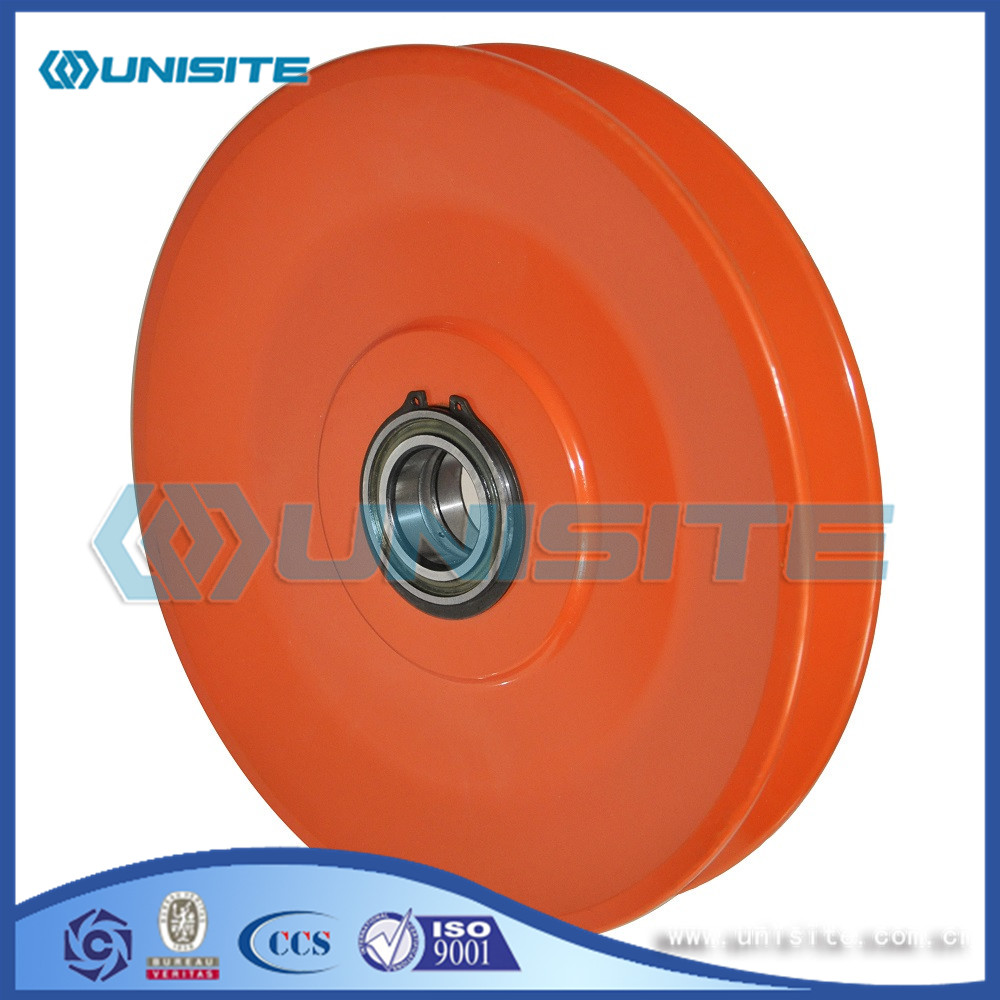

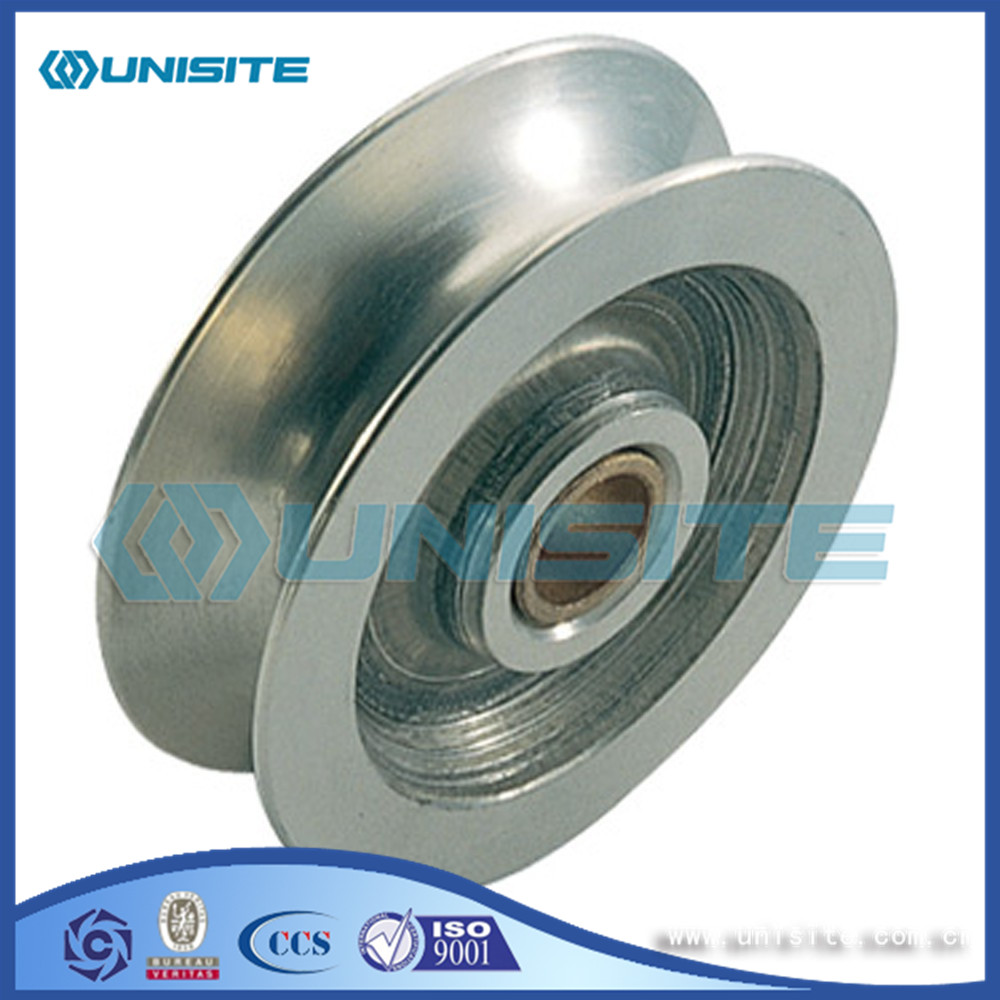

Photos of our Custom aluminum belt sheave

Certificates

- Material certificates by a classification society

- Inspection protocol

- Inspection reports tank testing

- NDT reports

- Official certificates for accessories and other equipment

- Fixed certificate: ISO9001, BV certificate, CCS certificate

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Structures > Sheave