Spiral Pipe Also known as spiral Steel Pipe and spiral welded pipe spiral pipe is low carbon structural steel or low alloy structural steel strips by a helix angle (called forming angle) rolled into a tube, then the tube seam welded together made, it can be with a narrow strip steel production of large diameter steel pipes.

Production Process

(1) raw materials that strip, wire, flux. We must go through rigorous physical and chemical testing before it is put.

(2) strip head and tail docking, single or double wire submerged arc welding, in rolled steel by automatic submerged arc welding.

(3) before forming the strip after flattening, cutting, trimming, planing, surface cleaning conveyor and I crimping process.

(4) the use of electric contact pressure gauge to control both sides of the conveyor pressure cylinder pressure to ensure the smooth delivery of the strip.

(5) the use of internal or external control roll forming.

(6) adopted the weld gap control device to ensure the weld gap to meet the welding requirements, diameter, the wrong side and the weld gap have been strictly controlled.

(7) within the welding and soldering are used outside the United States Lincoln welding machine for single or double wire submerged arc welding, thereby obtaining a stable welding specifications.

(8) finished welding the weld line continuous ultrasonic injury checks to ensure 100% coverage of non-destructive testing of spiral weld. If defective, automatic alarm and spraying tags, production workers so adjusting the process parameters, and remove defects.

(9) by air plasma cutting machine will cut a single tube.

(10) cut into a single steel pipe, steel pipe each batch must be strict inspection system, the mechanical properties of the weld inspection, chemical composition, fusion status, steel pipe surface quality and after NDT inspection to ensure that qualified Pipe Process before we can formally put into production.

(11) with a continuous sonic flaw marks the site of the weld, manual ultrasonic and X-ray review, if there are defects after repair again after destructive testing, until the confirmation defect has been eliminated.

(12) strip butt weld and intersect with spiral weld small joint where the pipe all through the X-ray television or film examination.

(13) of each pipe after hydrostatic test pressure radial seal. Test pressure and time by the steel pipe pressure microcomputer detection device strictly controlled. Test parameters are automatically printed record.

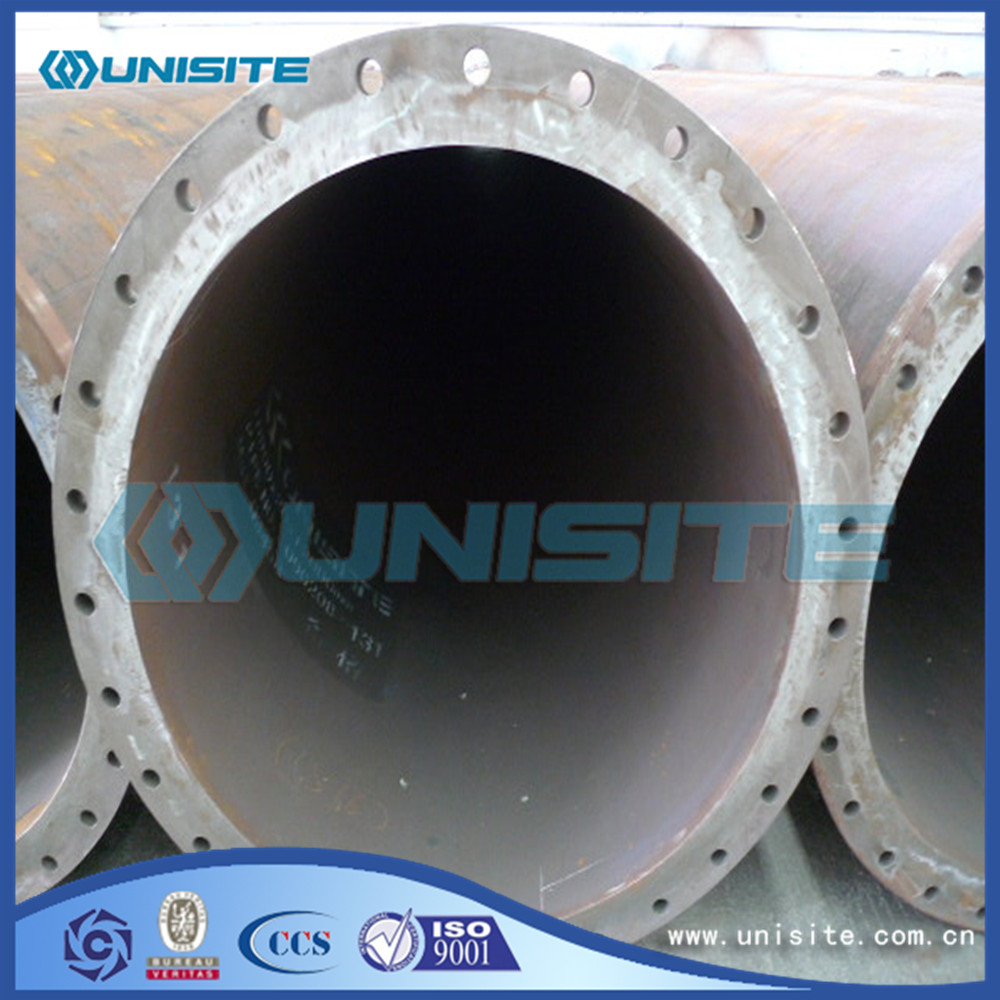

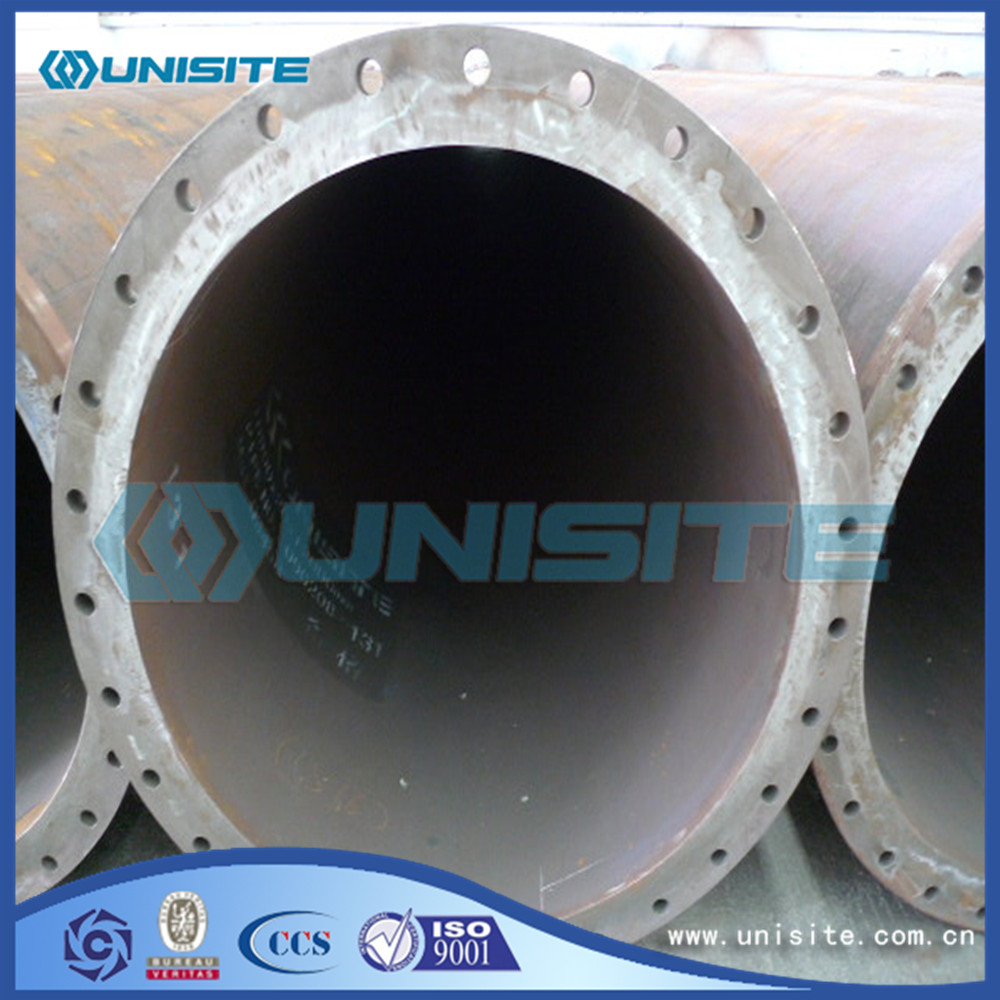

(14) pipe end machining, so that the end vertical, bevel and blunt edge be accurately controlled.

Accessories of our pipe line

A. Main

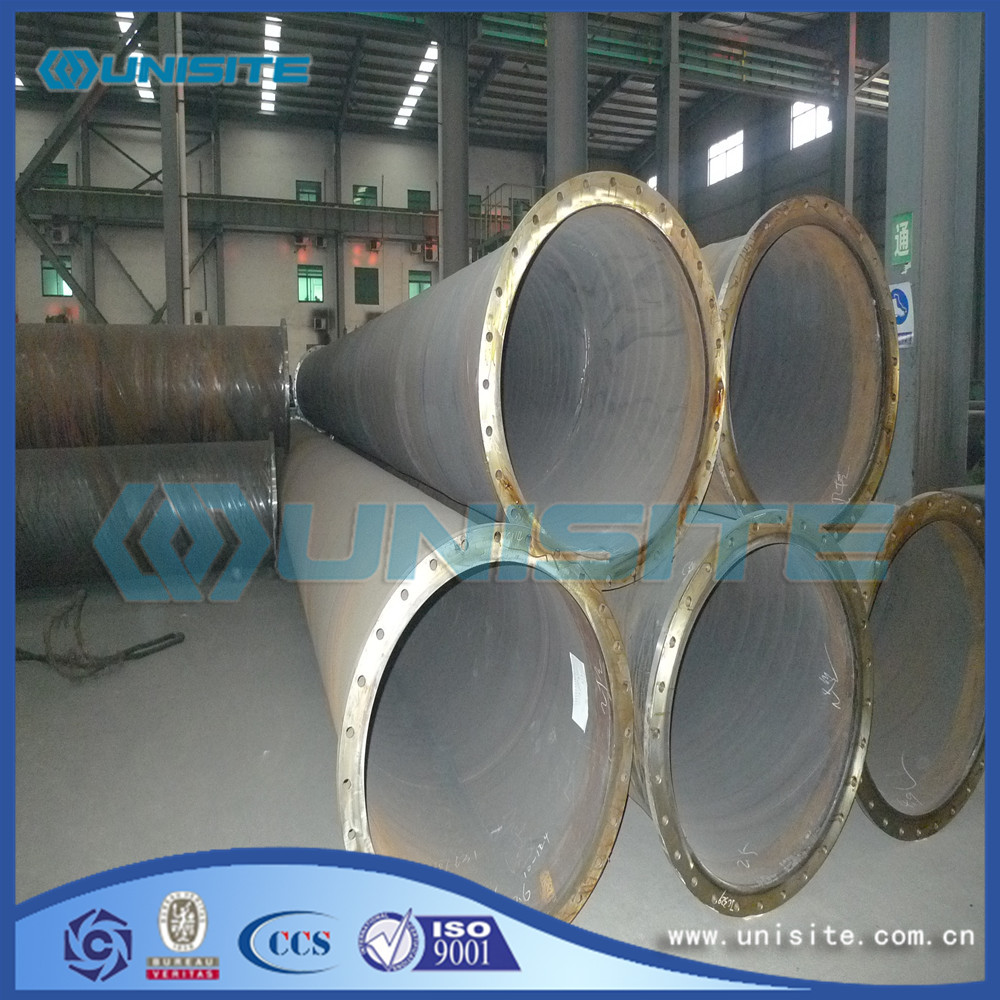

With flanges or without flanges at pipe ends.

We can weld flanges with good quality.

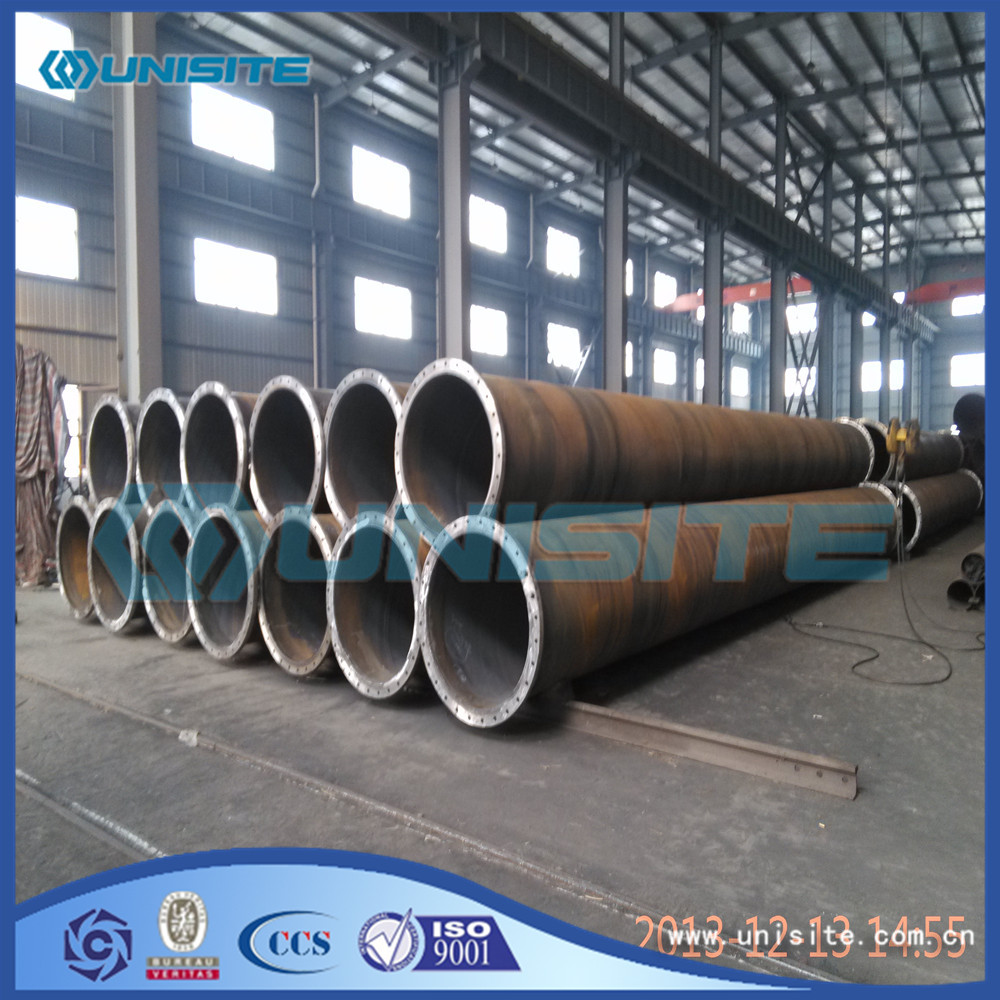

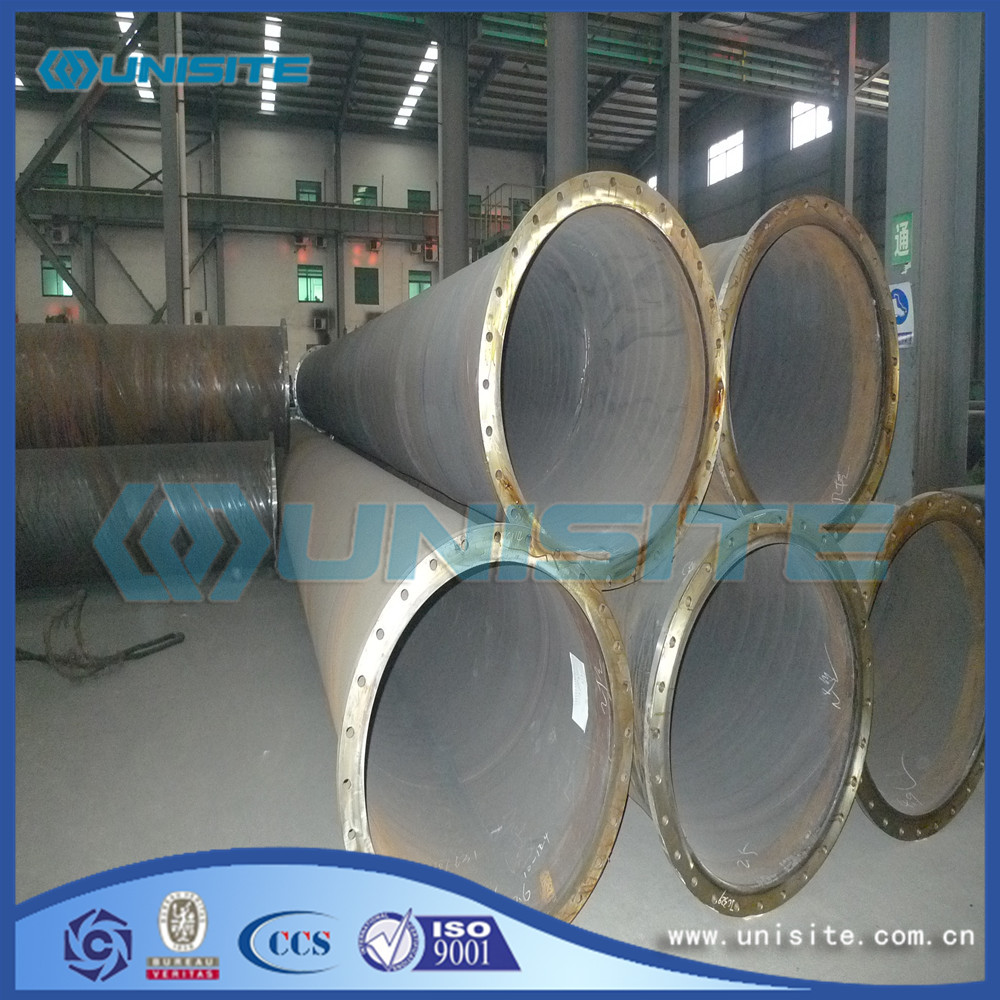

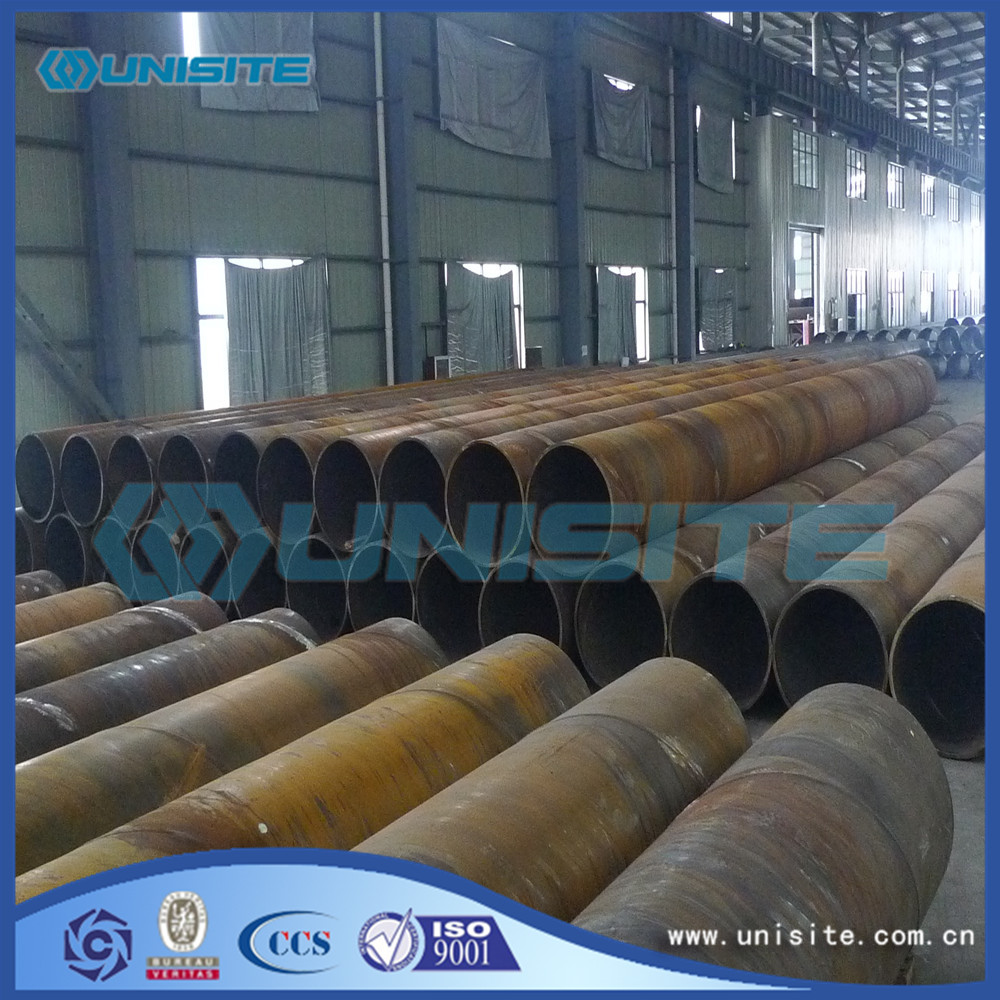

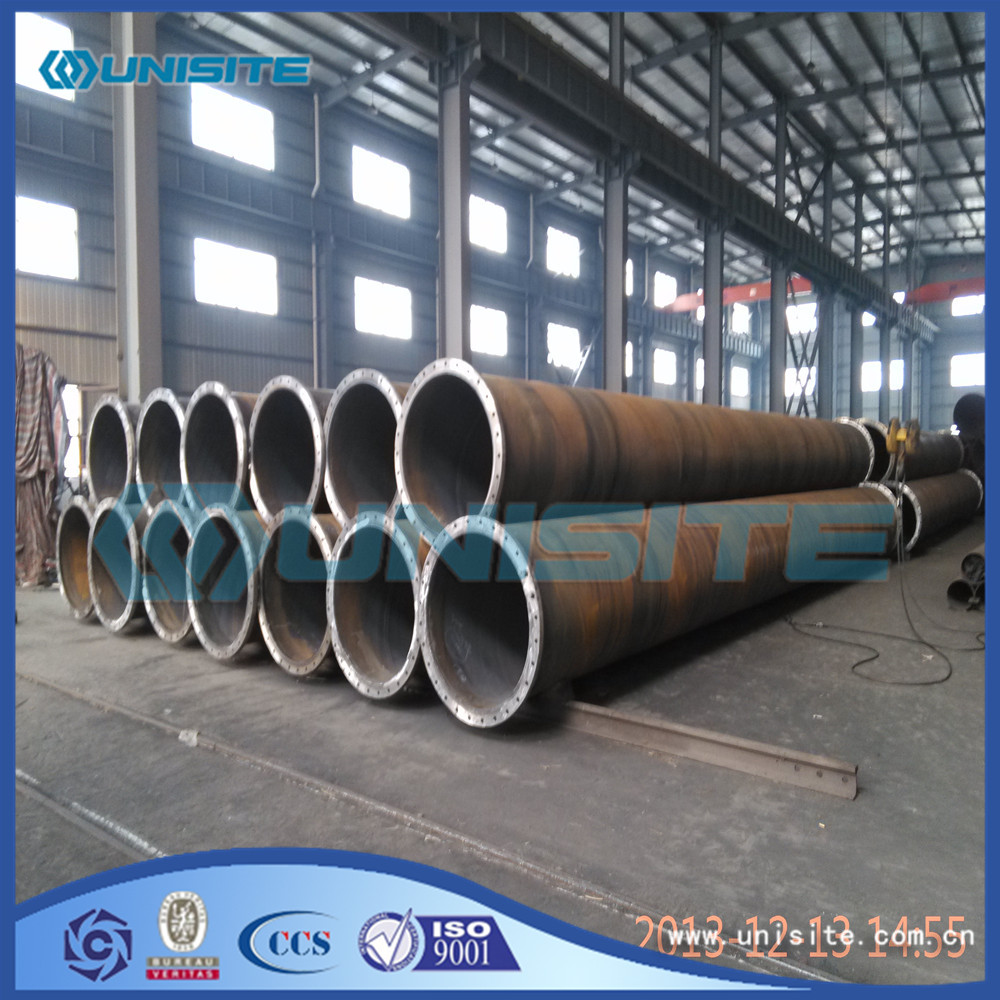

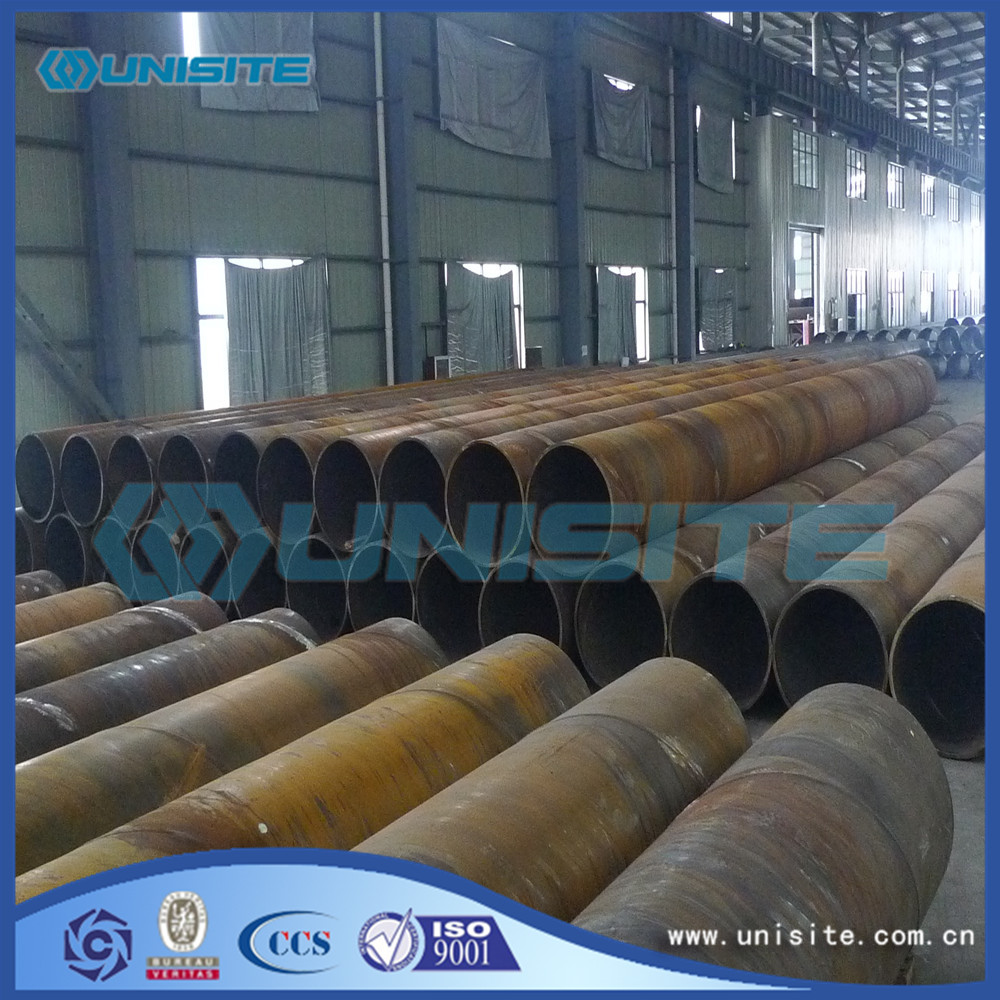

Photos of our Steel carbon spiral pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Spiral Pipe