Spiral characteristics: Longitudinal production process is simple, high production efficiency, low cost, rapid development. Spiral Welded Longitudinal generally higher than, can narrow the billet production of large diameter pipe, you can also use the same width of the billet production of different pipe diameters. However, compared with the same length of straight seam pipe, weld length of 30 to 100%, and lower production rate. Therefore, smaller diameter pipe is mostly a straight seam welding, large diameter spiral welded pipe for the most part.

The specifications of our pipe line

A. General

With advanced produce line, equipment and skilled workers, we can provide spiral, saw, Lsaw Steel Pipe and other pipes and structures.

Our main scope of pipe business are submerged pipe, Floating Pipe, and shore pipe for dredging, marine work, oil field etc.

B. Construction

The construction is to be built according to the drawing with rules of good workmanship.

C. Materials

All fabricated steelwork used in the construction of the pipe line will be to manufacturing standard of UniSite or other classification society.

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

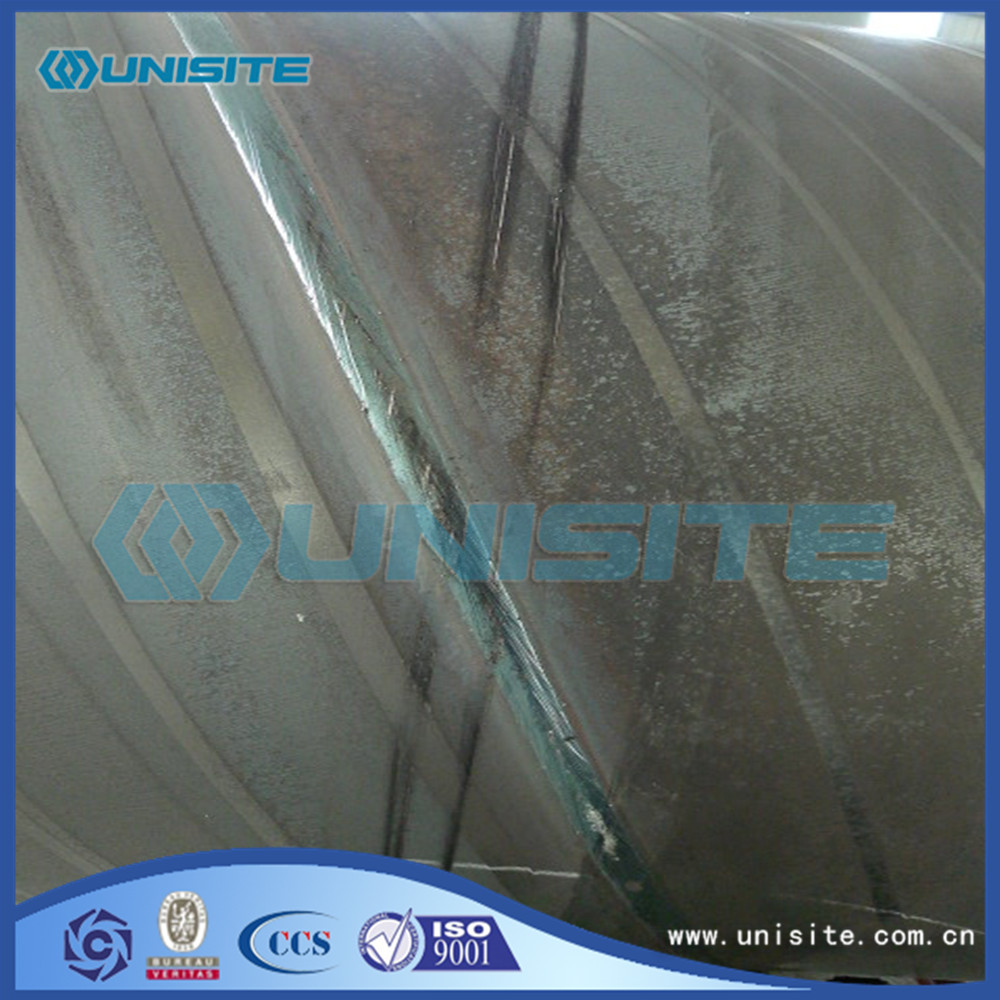

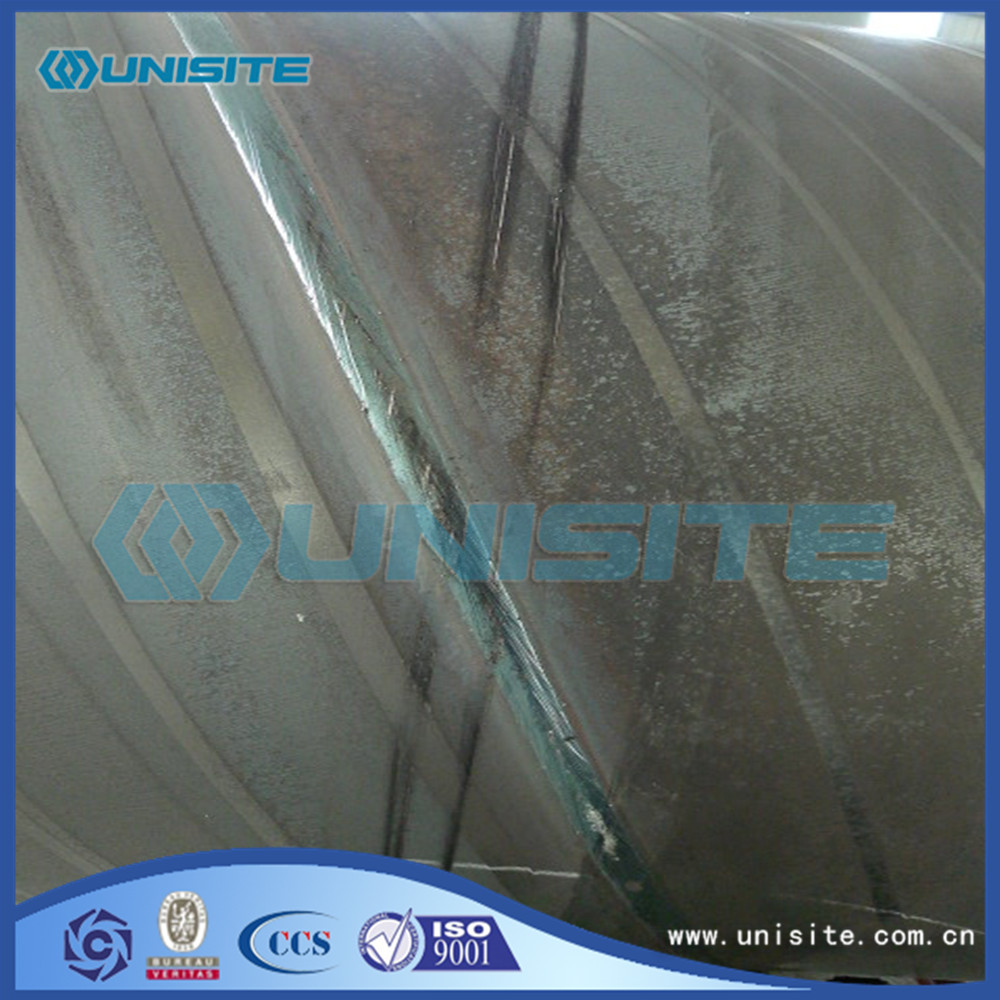

D. Welding

All welding will be performed in accordance with drawing and standard and UniSite experience and all welding will be continuous and full penetration.

Process of production

Spiral: Storage-Uncoiling-Flattening-Material inspection, shearing, crossing welding, edge milling, crimping press-Forming-Inside and Outside welding, de-magnetization, cutting-Ultrasonic testing-Cleaning, inspection, grinding-Pipe end expanding-Hydrostatic testing-Ultrasonic testing and X-ray testing-Beveling and chamfering-Weighting and measuring-Marking-Final inspection-Storage

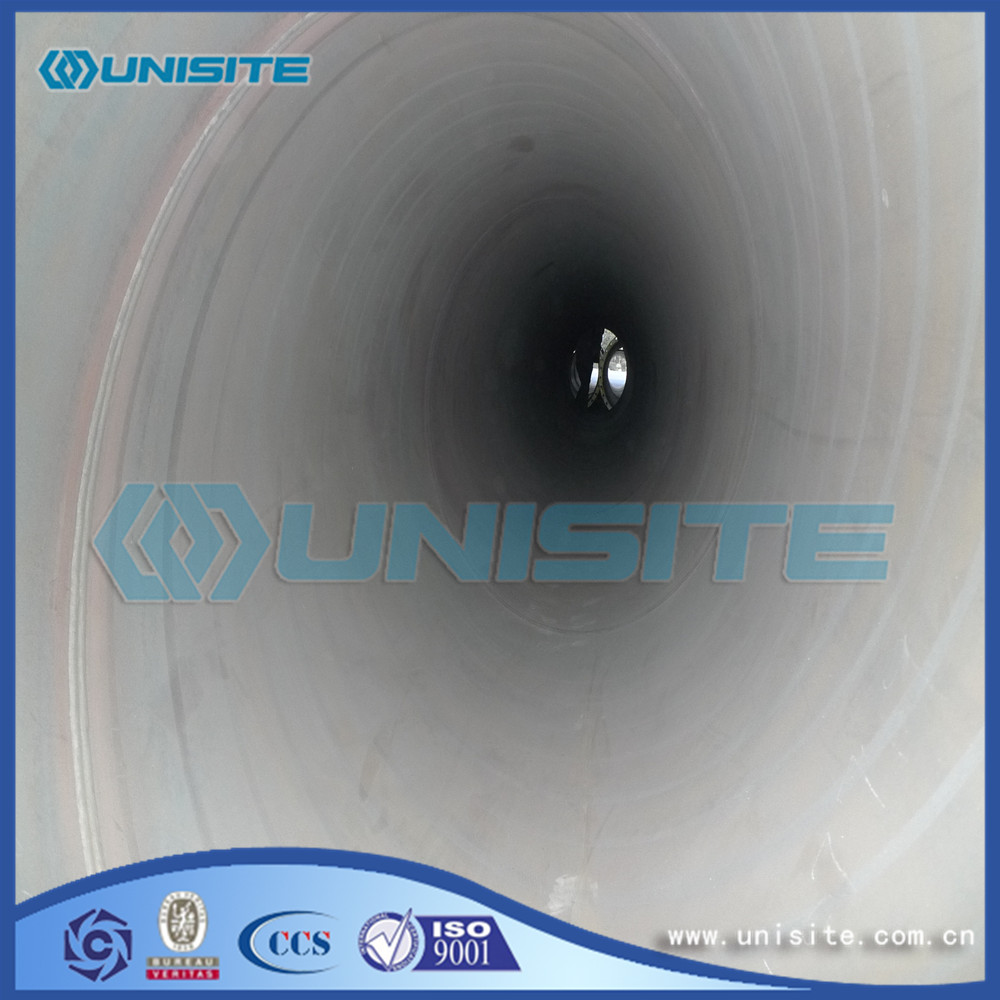

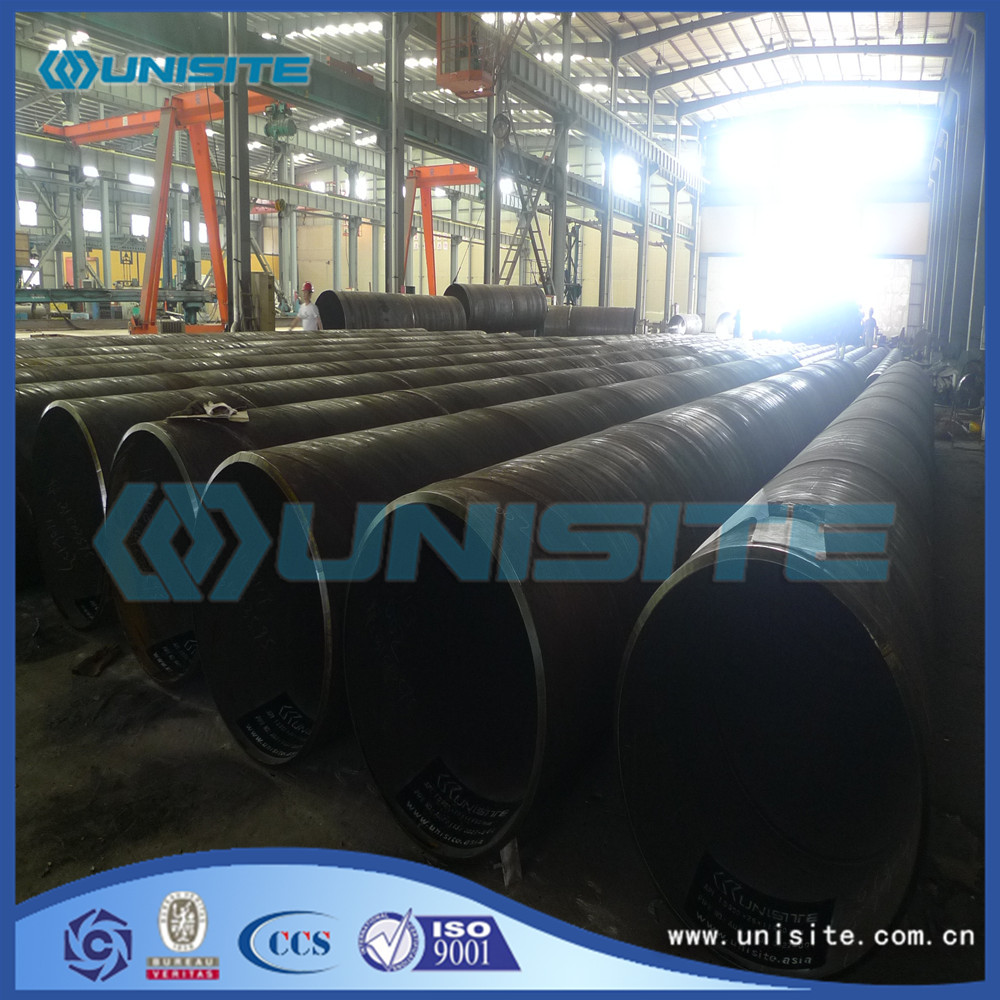

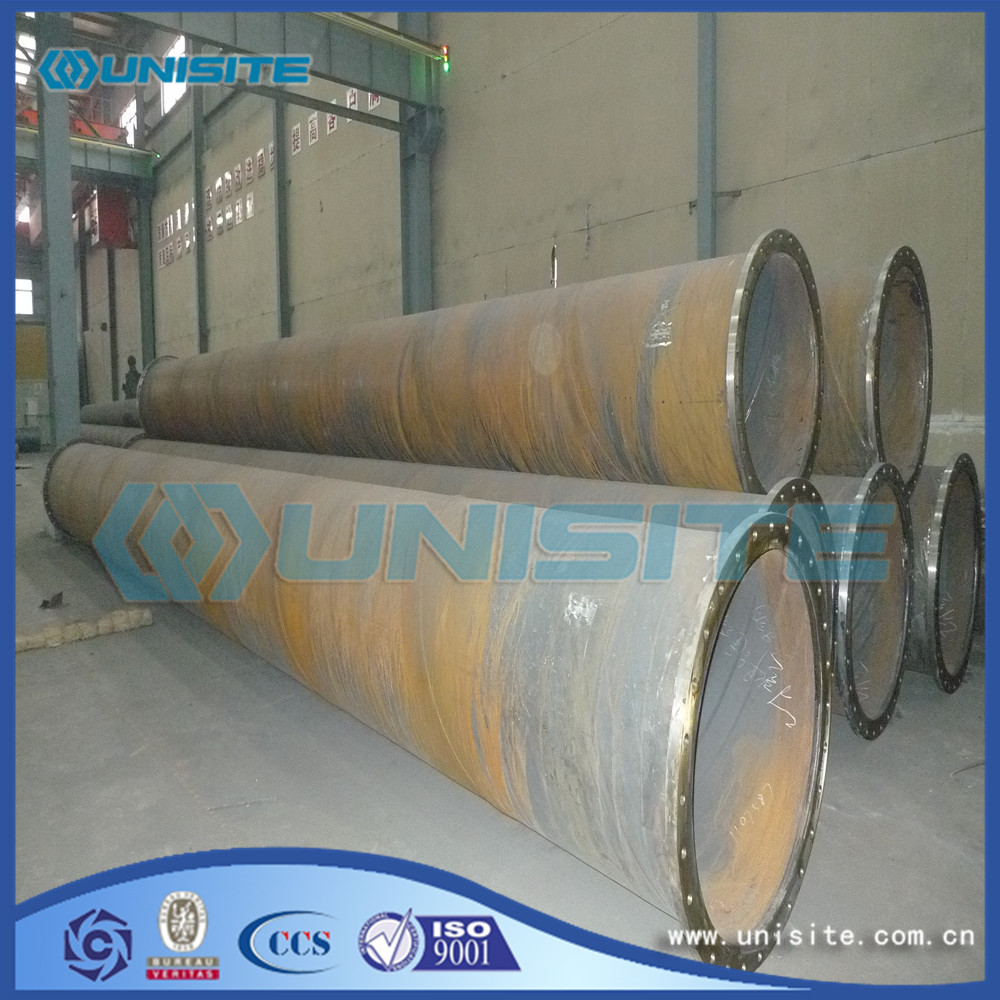

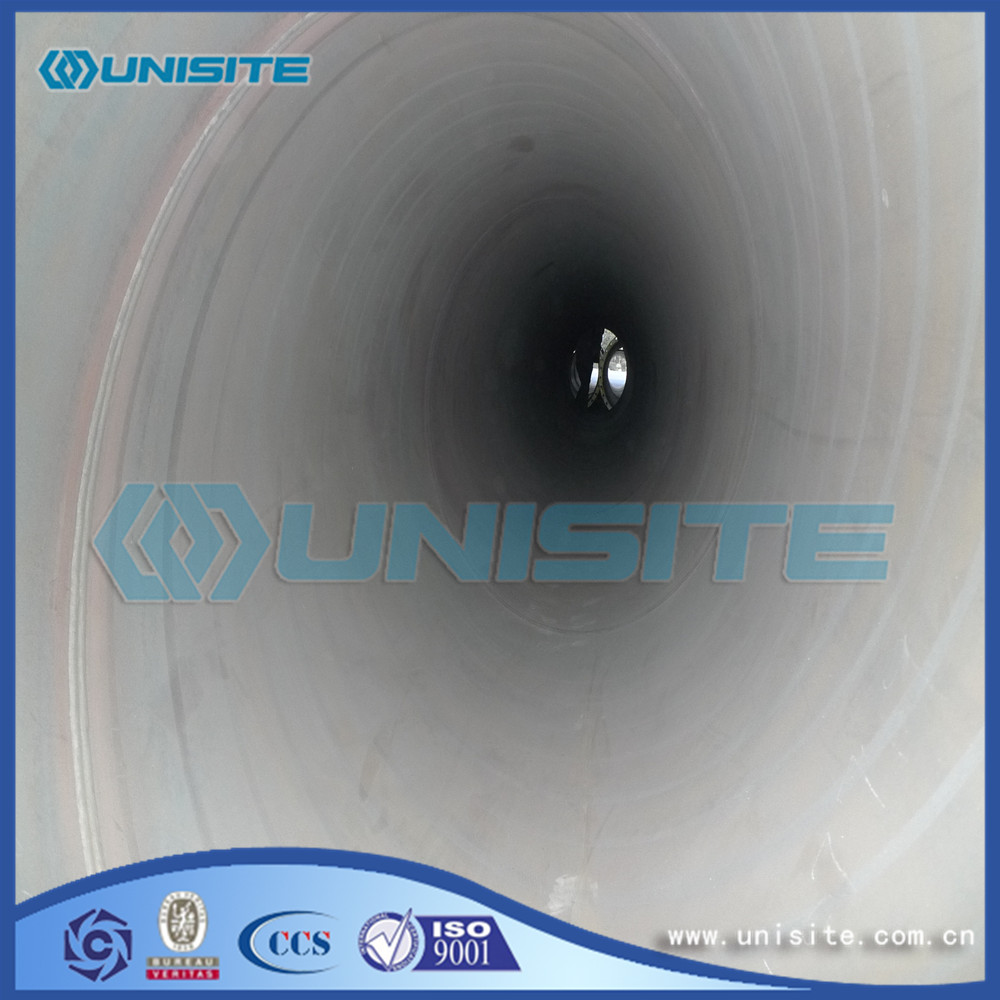

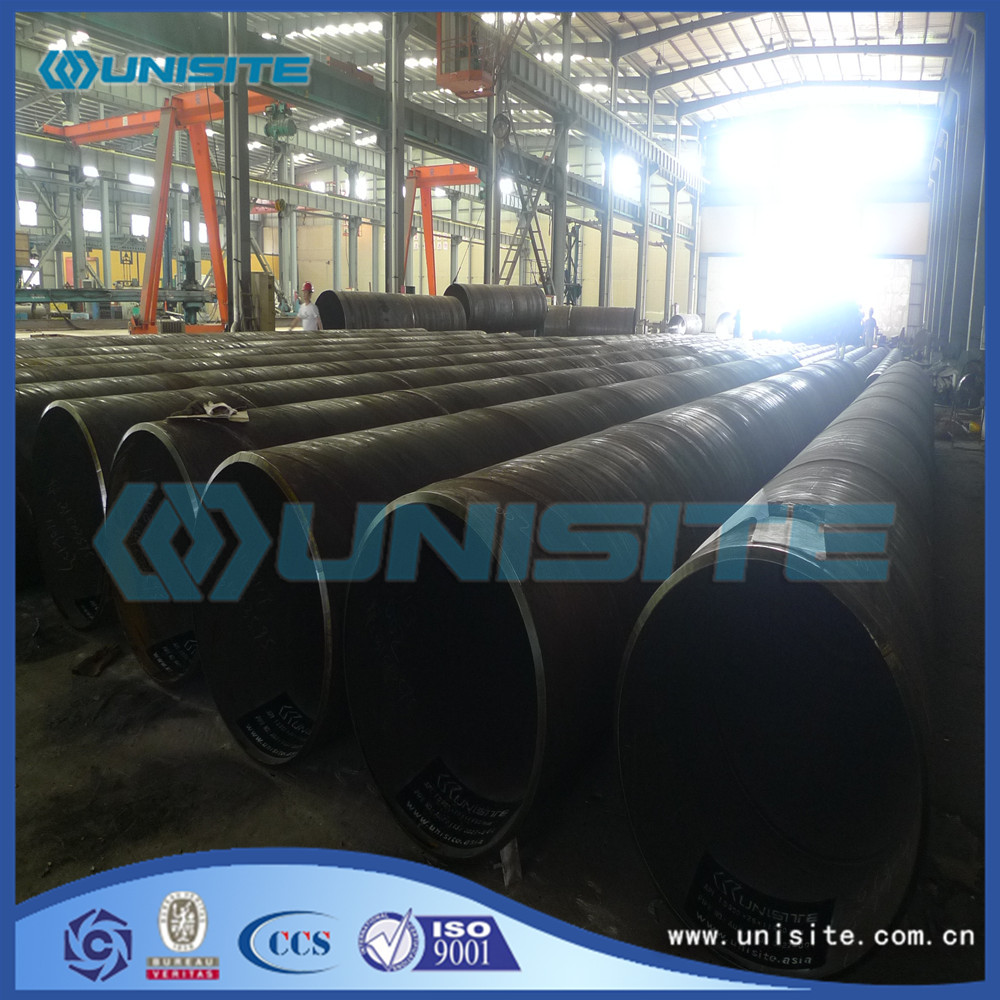

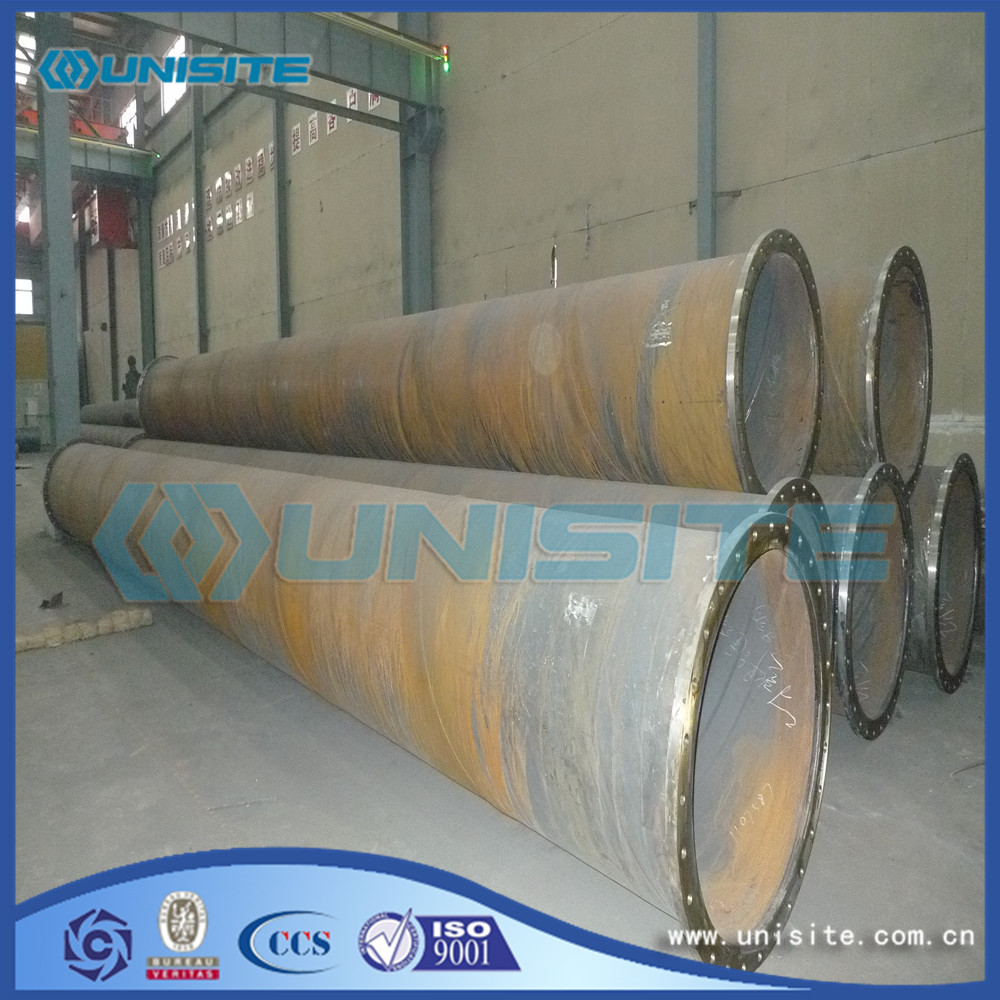

Photos of our Round carbon spiral weld Steel Pipe

Certificates

- Material certificates EN10204 3.1b

- Inspection protocol

- NDT reports

- Fixed certificate: ISO9001, BV certificate, API

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Spiral Pipe