Stainless steel tube inner diameter above 6.0 mm, wall thickness in 13mm following annealing of stainless steel tubing can used to W-B75 type Merriam Webster Hardness Meter, it tests the very fast and easy, suitable for of stainless steel pipes do quick and nondestructive inspection. The inner diameter of the stainless steel tube is larger than 30mm, and the wall thickness is larger than that of 1.2mm stainless Steel Pipe. The hardness of HRB and HRC is tested by using the hardness tester.

Corrosion resistance of stainless steel

All metals react with oxygen in the atmosphere to form an oxide film on the surface. Unfortunately, the formation of iron oxide on ordinary carbon steel to continue to oxidize, so that the corrosion continues to expand, and ultimately the formation of holes.

Carbon steel surfaces can be protected by the use of paint or oxidation resistant metals (e.g., zinc, nickel, and chromium), but, as is known, the protection is only a thin film. If the protective layer is destroyed, the following steel begins to rust.

The corrosion resistance of the stainless steel depends on the chromium, but because the chromium is one of the components of the steel, so the protection method is not the same.

The corrosion resistance of steel was significantly increased when the chromium content was 10.5%, but the chromium content was much higher, although it could still improve the corrosion resistance, but it was not obvious. The reason is that the type of oxide on the surface of the steel is changed into a kind of surface oxide which is similar to the pure chromium metal. This close adhesion chromium oxide protection surface, prevent further oxidation. This very thin oxide layers, through which you can see the natural luster of steel surface, the stainless steel has a unique surface. Moreover, if the surface is damaged, the exposed steel surface and atmospheric reaction for self repair, re formed this passive film, continue to play a protective role.

Therefore, all of the stainless steel has a common characteristic, that is, the chromium content in more than 10.5%.

The relevant material and construction applications usually only six. They all contain 17 ~ 22% chromium, good steel containing nickel. The addition of molybdenum can improve the atmospheric corrosion resistance, especially the corrosion resistance of the air containing chloride.

Technology

Offering our client best possible and most sustainable solutions to their requirement. Production procedure:

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Casting, forging, stamping, machining if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Surface treatment; Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step7: Package, Loading and Lashing when delivery;

Photos of our Equipment

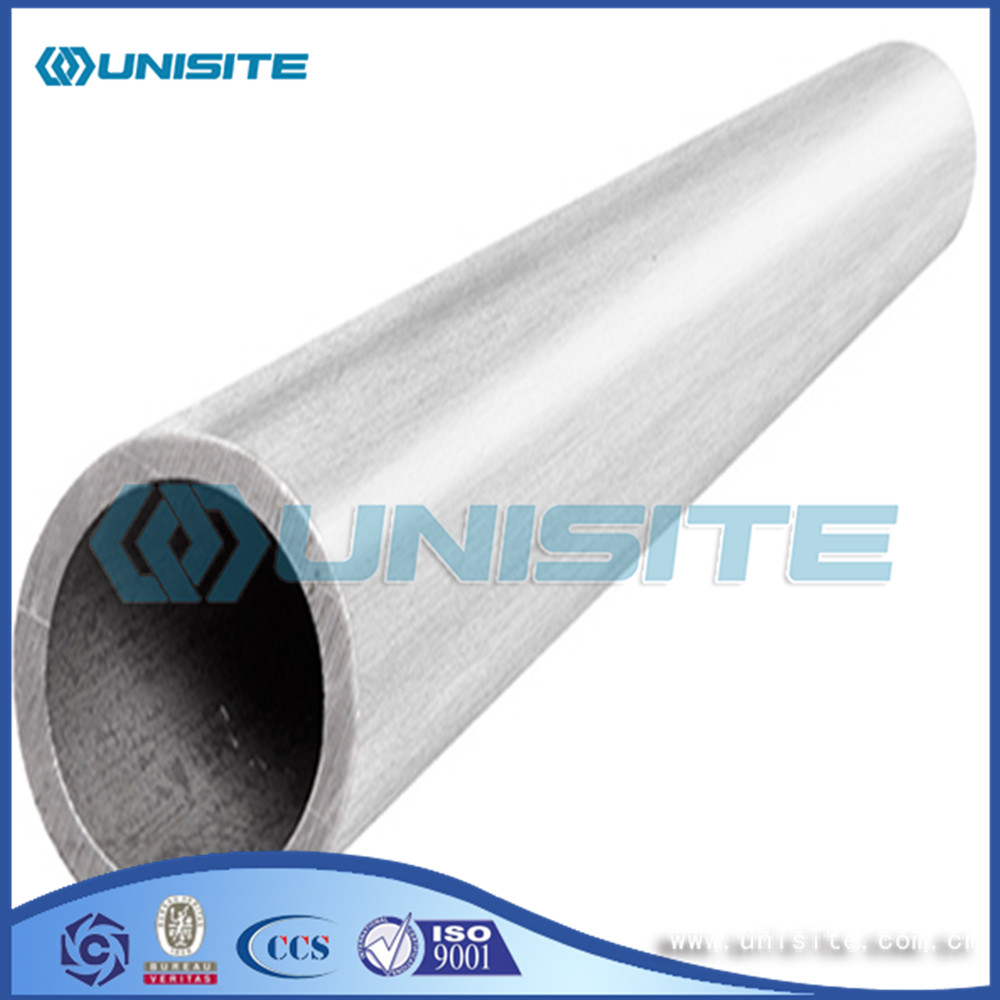

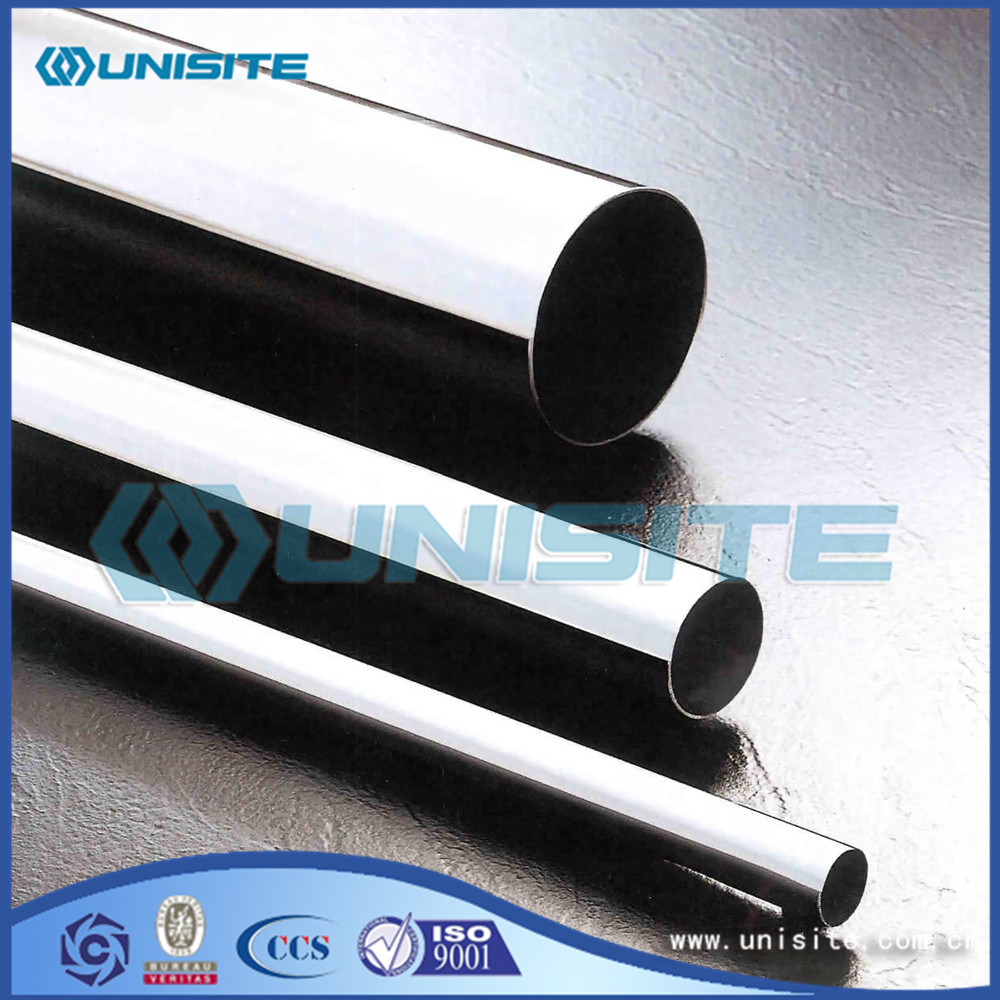

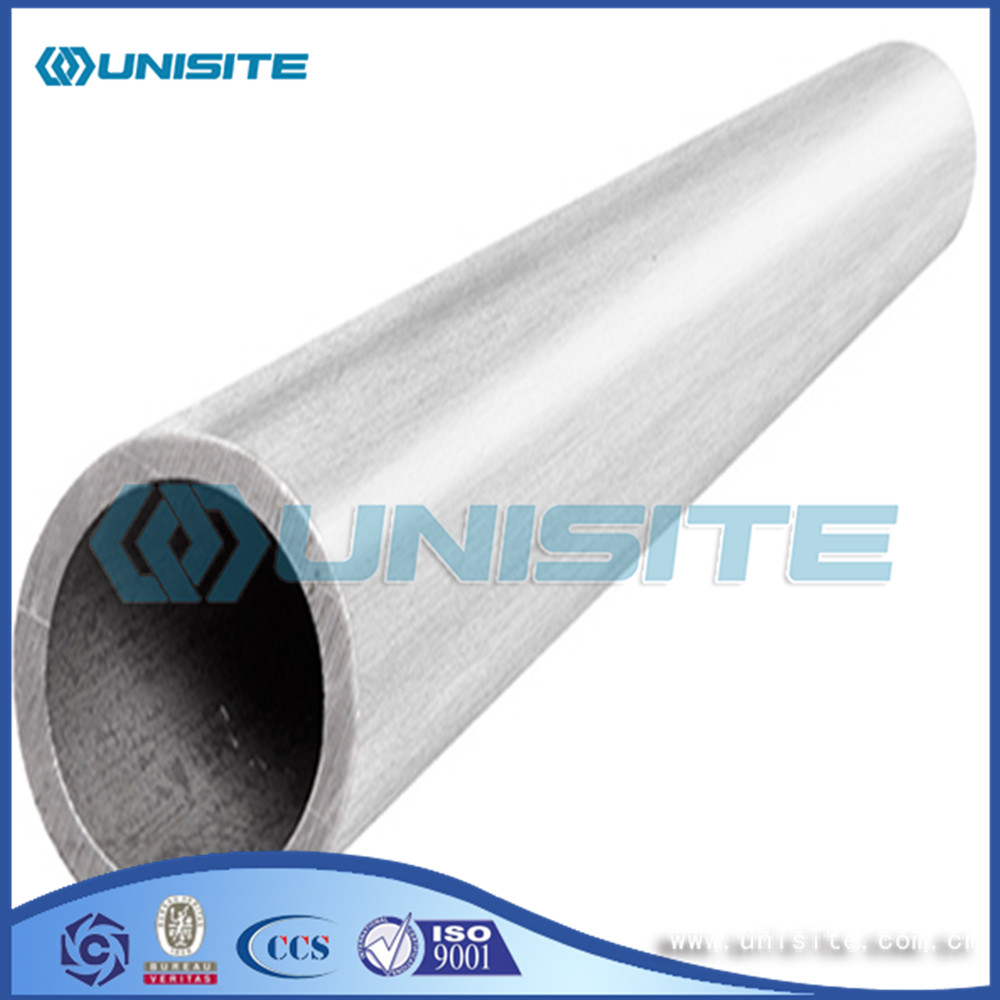

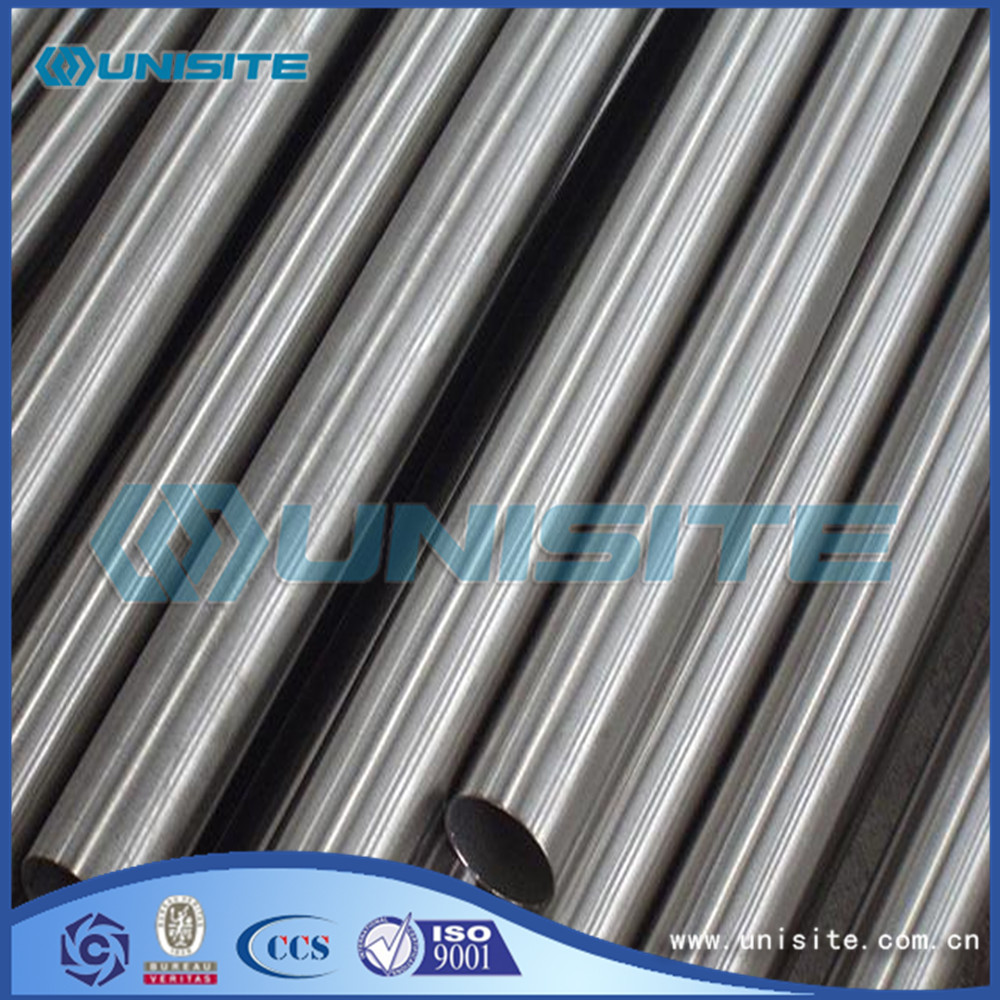

Photos of our Stainless steel exhausted round pipe

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Stainless Pipe