Liquefied petroleum gas (LPG) can be at room temperature by pressure or frozen under atmospheric pressure and liquefaction. According to the method of liquefied LPG ship is divided into pressure type, half frozen pressure type and frozen type 3 kinds. Pressure type LPG ship is several pressure tank is installed in the boat, the maintenance of liquefied petroleum gas at high pressure liquid. This simple form structure, 30 s have been, since capacity under 6000 m 3 boat is still widely used.

Liquefied petroleum gas ships, LPG storage tank water injection process to seal

water injection process to seal

1. the nature of the LPG

(1) the density of gaseous LPG is bigger than air, leaking after accumulate near the ground. Easy to spread, LPG explosion limit of about 2% ~ 9%, and lower explosive limit is lower in the event of leakage, LPG can quickly form the explosive gas mixture in the small scope, very dangerous.

(2) liquid LPG lighter than water.

(3) saturated vapour pressure of LPG is higher, gasification speed, in the process of from liquid to gas, in a short period of time can absorb a lot of heat. If spray to the body, can lead to local cooling surface of the skin and cause frostbite.

2. process principle

As the liquid LPG lighter than water, if the tank bottom valve, flange and fittings in the leaking, can spread to the storage tank through the process piping with water, water in order to LPG and the LPG from the leak point, reduce the possibility of LPG leakage into the surrounding environment (2, 3].For the implementation of measures to strive for the time, such as plugging, pour tank and reduce liquid LPG overflowing capacity, reduce the damage to the operator.

3. process

Process as shown in figure 1.Water pump and fire hose and fire cisterns, ensure the continuity and reliability of water supply. The two pump discharge pipeline must be equipped with check valve, once when the pressure of LPG pipeline LPG will not reverse flows into the fire water pipelines. Saturated vapor pressure LPG room temperature is higher, about 0.4 MPa to 0.8 MPa, so choosing pump should be selected when high lift pump, ensure the smooth water into the tank. Appropriate to a backup pump in parallel, two dangerous when pump can work at the same time, more reliable.

4. the process of implementation

After the leakage of once found in production, find leak point, when the other method is difficult to implement, immediately drive water injection pump. If the leak is small, because in the process of leakage of LPG gasification and heat quickly, make the leakage around the temperature fell sharply, encounter cold ice ice had formed after it reaches the leak plugging, can have the effect of temporary plugging. If the leak point gap unable to form larger ice wall, continue to spread to the storage tank water injection. Liquid LPG lighter than water, so the water in the tank will LPG injection on the surface, make the LPG from the leak point. Now spewing from the leak point mainly water rather than pure LPG, plugging again with his method. In the process of collision, can open the tank top tossing in valve, tossing in gaseous LPG, such already is not easy to form the risk, and reduce the pressure in the tank.

5. The advantages of process

(1) the process is simple, start quickly, quick effect, easy to implement, can play a role of emergency.

(2) the liquid is mainly from the leak water, reduce the collision process of LPG gushing quantity and delay the formation of explosive blending toughening, reduce the risks of operating personnel frostbite, decrease the difficulty of the operation for the implementation of plugging, cans and other measures for the time.

(3) implementation of empty radiation reduces the leak point pressure, easy to leak.

Quality management

UniSite have a perfect managing system and quality control system which from initial work.

ISO9001-2008/CCS; BV manufacturer capability qualification.

Taken part in the CHINA DREDGING ASSOCIATION

Quality, health, safety and environment (QHSE)

Production guidelines

In-house safety training to our staff

Checking all the production equipment periodically

Preventing pollution, accidents and health hazards, auditing

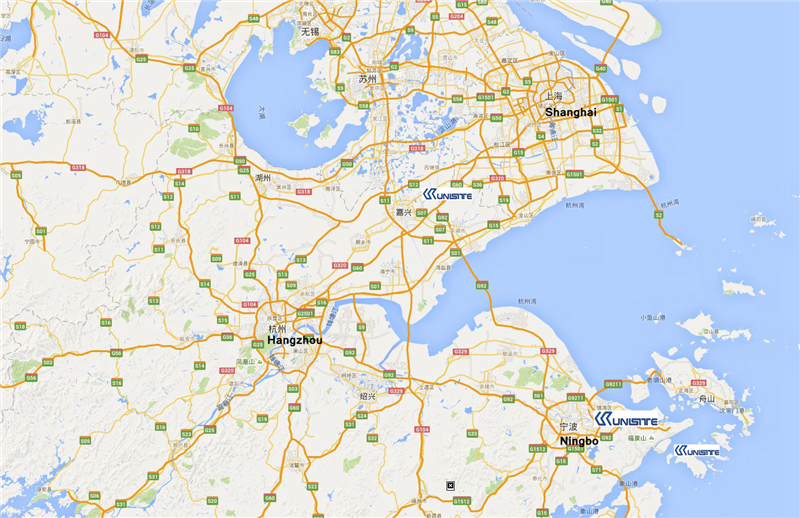

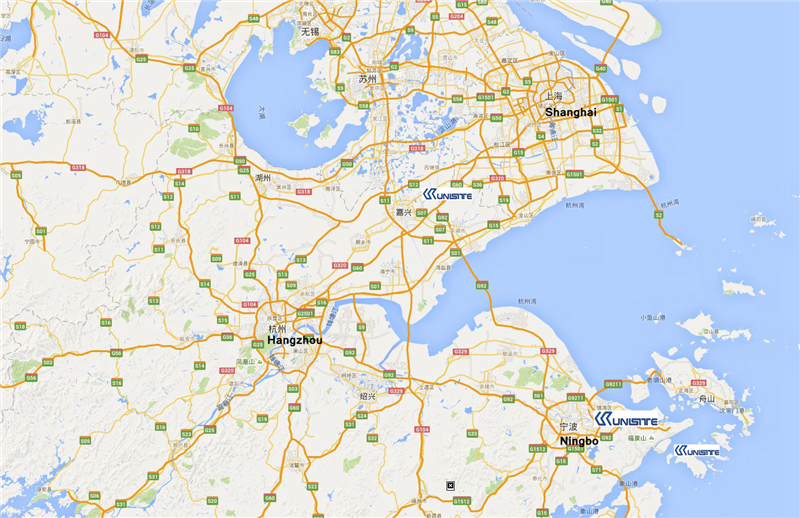

UniSite`s core activity: serve for dredging and marine projects .Provide service and relevant parts for dredgers, including Dredger construction, repairing and maintenance.Provide items for dredging, land reclamation, offshore, marine engineering, piling works, municipal engineering, mechanical engineering, oilfield projects and environmental remediation projects.

Photos of our LPG marine vesssel for sale

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Chemical Vessel > LPG Vessel