Selection of Pump Shell material: A strength; B corrosion resistance; C wear resistance; D casting and machining performance; E weld repair performance; F cost.

For most liquid applications, gray iron is a good material for making pump shell.For single-stage pumps, usually gray cast iron has sufficient strength to resist the pressure generated.Ductile iron is widely used in medium pressure and temperature range.Ni-resist is often used as pump material in where gray cast iron and ductile iron are not sufficiently corrosion-resistant.

In recent years, a new type of corrosion resistant high nickel cast iron material with good welding properties (named D2W) has been developed, with a small amount of niobium in order to improve its welding performance. The typical austenitic cast iron contains 15%~20% nickel, which is widely used in brine.

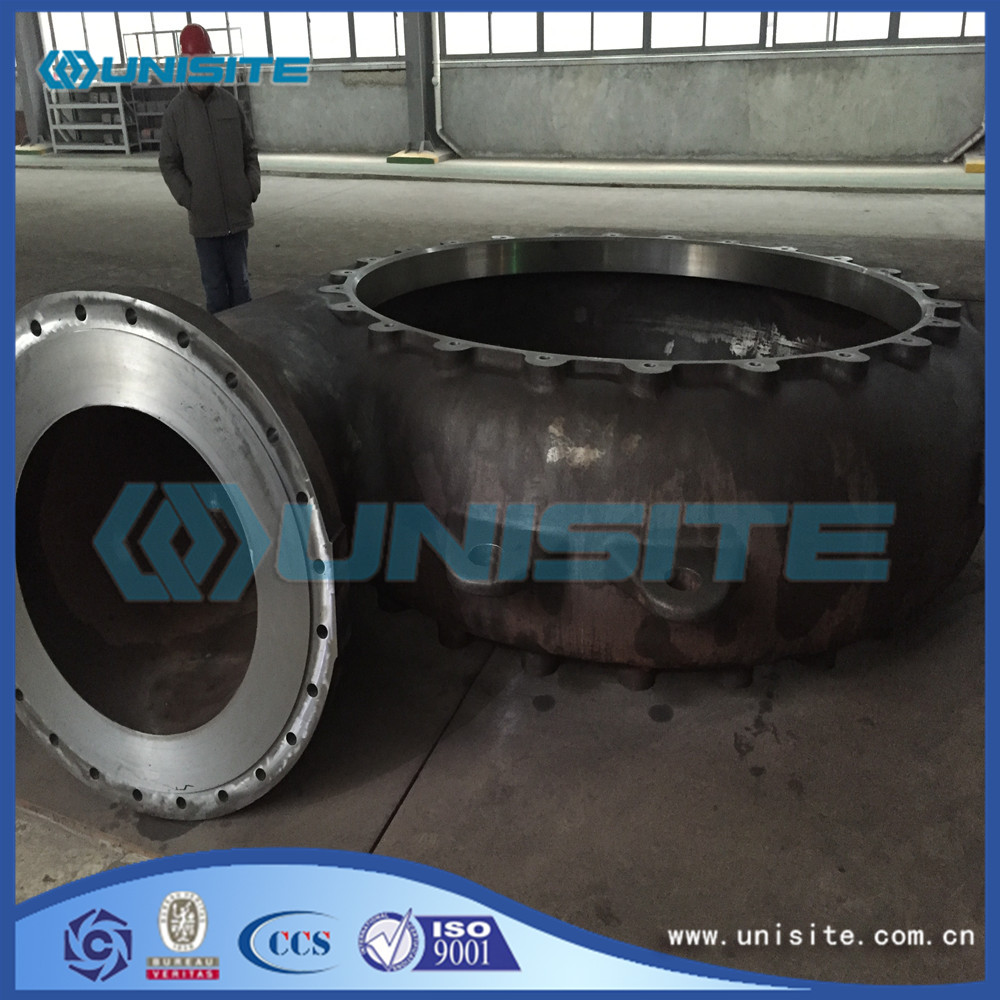

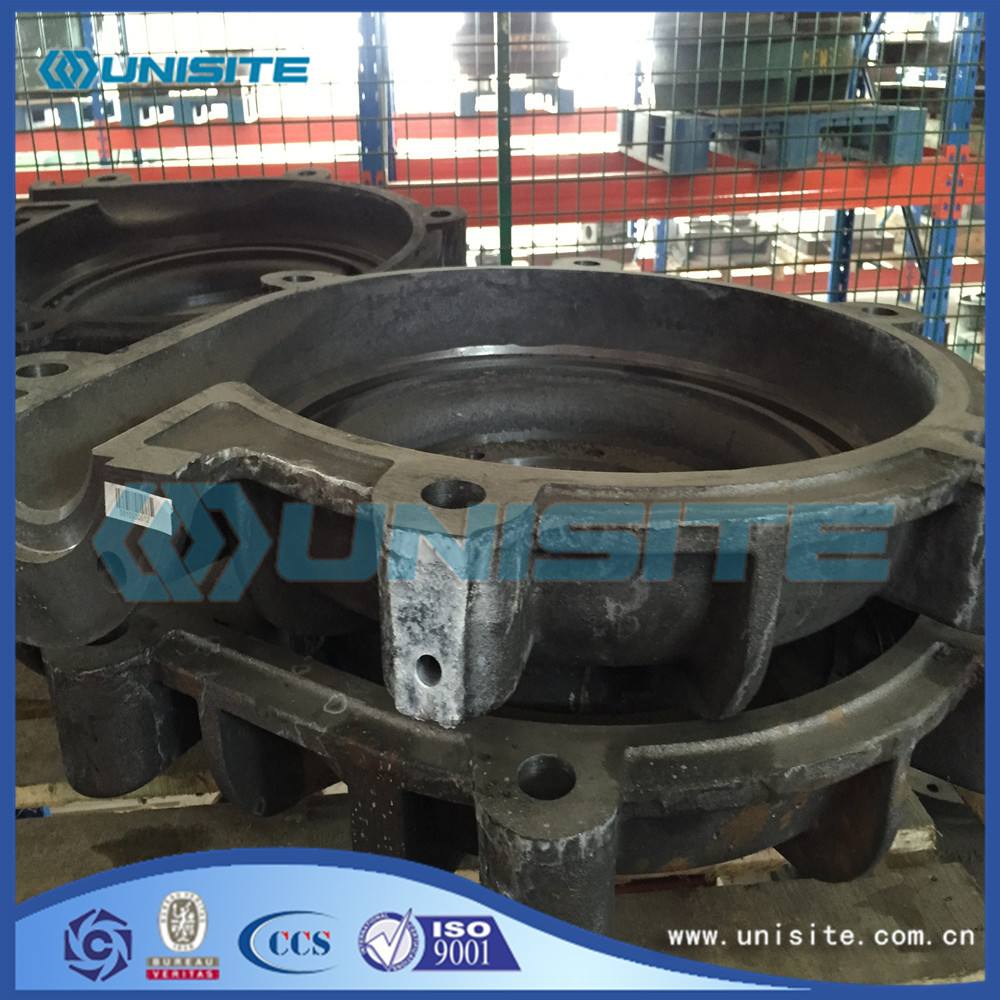

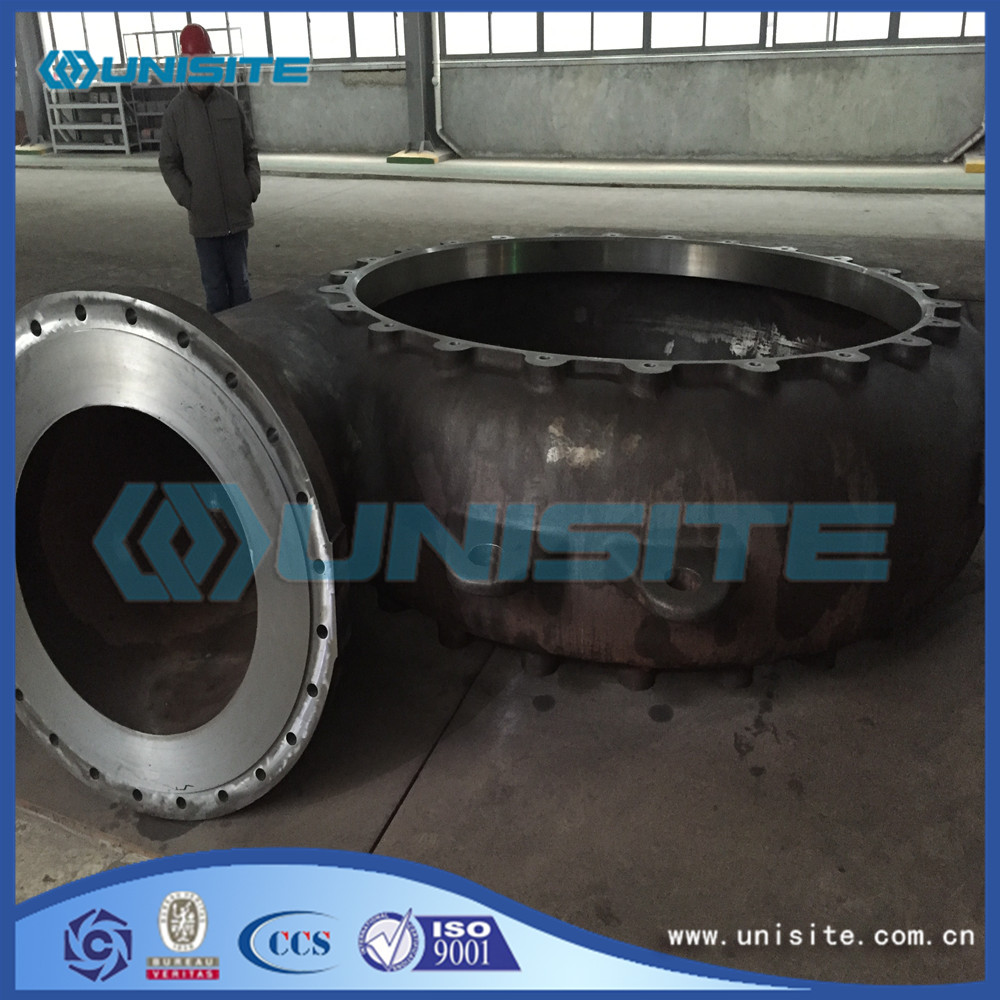

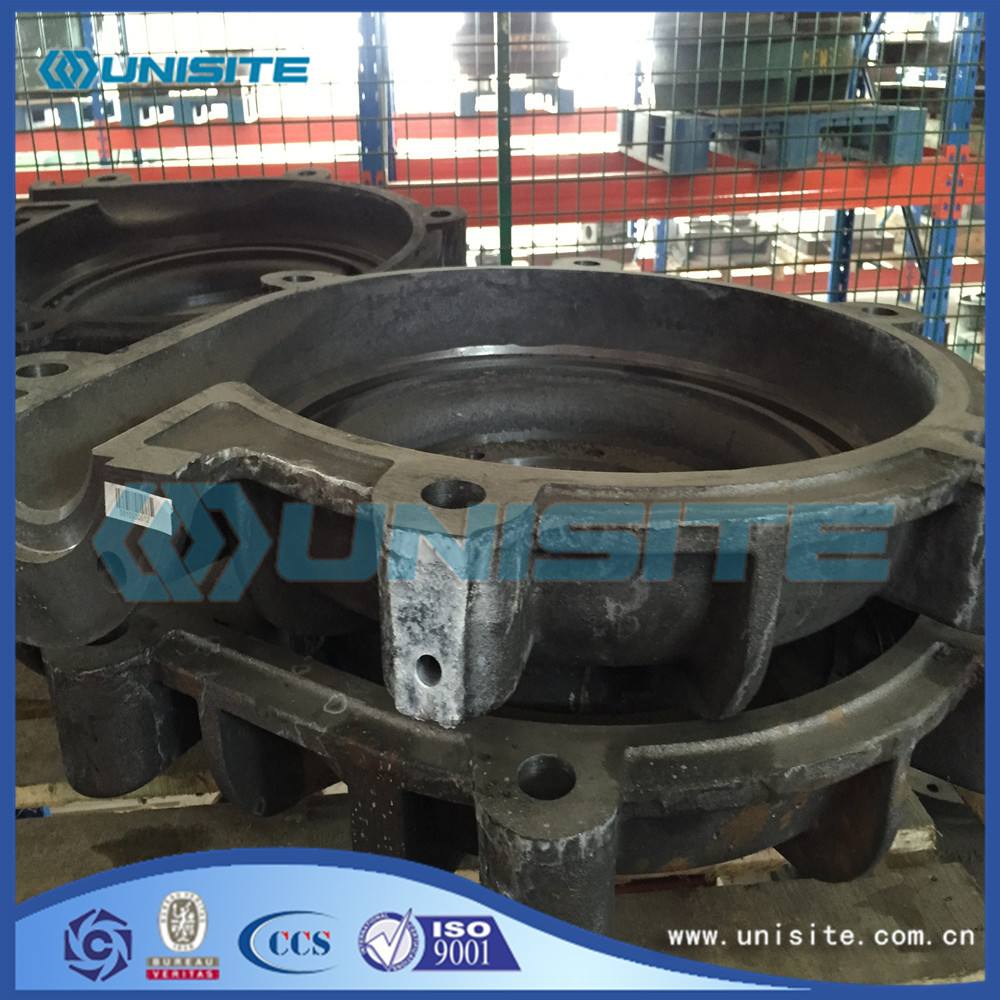

material:high chromium cast iron

The Cating Steel Dredging Pump Shell is made up of high chromium cast iron.High chromium cast iron is short for high chromium white - wear resistant cast iron, it is a kind of anti - wear material with good performance and special attention. It at much higher than alloy steel wear resistance, much higher toughness and strength than the general white cast iron, at the same time it also has good resistance to high temperature and corrosion resistance, combined with the production convenient, cost is moderate, so is known as the contemporary one of the most excellent anti-wear material.

Company introduction

UniSite group has a perfect managing system and our staff who are professional in technology are committed, passionate, efficient.

Safety & quality are the key factors of UniSite group with good QHSE experience and ISO9001/BV certificate.

With professionalism, vitality, innovation, respect, team spirit, UniSite culture (corporate values, corporate philosophy and behavior shaping) is continuously developing, along with our company from its foundation.

UniSite group is able to offer our client best possible and most sustainable solutions to their requirement.

Main advantages of UniSite 1) No customer quality complaints for 10years

We have a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

You can see the quality of all our previous orders were guaranteed based on our good procedure and service.

2) Born from military factory, with rigorous team having rich experience of military marine products

We UniSite started as a small contractor of ship building works in military factory in Ningbo 10 years ago. After several years of accumulation, the team had owned a certain number of experienced managers, engineers, technicians and workers who have rich experience in military shipping building and have good marine practice.

3) Involved in many big projects all over the world

We have involved in many projects all over the world that we have ability to participate in big projects.

4) BV/CCS approval for manufacturer capability qualification

We passed the BV/CCS approval for manufacturer capability qualification for dredging & Dredger products.

5) Our existing customers are the world`s top five hundred

----------------------------------------------------------------------------------------------------------------------

6) To produce our products with strict standards of military products

Our team have rich experience in military marine products with military standard.

7) Outstanding in multiple fields

Besides dredging and marine engineering, we are also specialized in providing comprehensive service of municipal engineering, mechanical engineering, oilfield projects and environmental remediation projects.

8) Assure for large production capacity with many advanced equipment

Integrate all resources, UniSite have large advanced equipment and is able to do most large products of marine products including pontoons

Bending machining, rolling machine with 150mm, SAW equipment, manual welding equipment, Laser Thermometer, Electrode dryer, cutting machine, milling machine, electrical element, big Welding roller stand, Box -type electric furnace, special inspection tools, Lifting Gantry 200T, 100T, floating crane 1200T-

Photos of Cating Steel dredging Pump Shell

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Pump And Spare Parts > Pump Shell