As of 2009, buried arc welding Steel Pipe's usual standards are generally divided into: SY/T5037-2000 (ministerial standard, also known as the common fluid conveying pipe with spiral submerged arc welded pipe), GB/T9711.1-1997 (GB, also known as oil and natural gas industry transporting pipe delivery technical conditions of the first part: a grade steel tube (as of 2009 strict requirements have GB/T9711.2 B grade steel pipe), api-5l (American Petroleum Institute, also called pipeline steel; which is divided into two levels: PSL1 and PSL2), SY/T5040-92 (pile with spiral submerged arc Welded Steel Pipe).

Performance advantages of Saw Pipe

Performance advantages of heat preservation and corrosion protection and double side submerged arc welded pipe

1. the heat preservation performance is good, the heat loss is only 25% of the traditional double side submerged arc welded pipe, the long-term operation can save a lot of energy, reduce the energy cost significantly.

2.has a strong waterproof and corrosion resistance, without attached pipe trench, can be directly buried in the ground or water, construction is simple and rapid and low cost.

3. the double face submerged arc welded pipe has good corrosion resistance and impact resistance at low temperature, and can be directly buried in the ground.

4. service life of up to 30-50 years, the correct installation and use of double-sided submerged arc welded pipe repair costs are extremely low.

5. can set the alarm system, automatic detection of the double side submerged arc welded pipe leakage fault, accurate indication of the fault location and automatic alarm.

Submerged arc welding steel pipe material

Q235A, Q23b, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, Q345 L245 L290 X42 X80 0Cr18Ni11Nb. X46 X70

Process of production

JCOE(LSAW): Storage-Plate feeding-Ultrasonic inspection-Flame cutting-Edge milling-Crimping press-JCO shaping-Prewelding-Inside welding-Outside welding-Ultrasonic inspection-Mend welding-Ultrasonic inspection-Tube expander-Rounding-Alignment-Beveling and chamfering-Hydrostatic testing-X-ray testing-Weighting and measuring-Marking-Final inspection-Storage

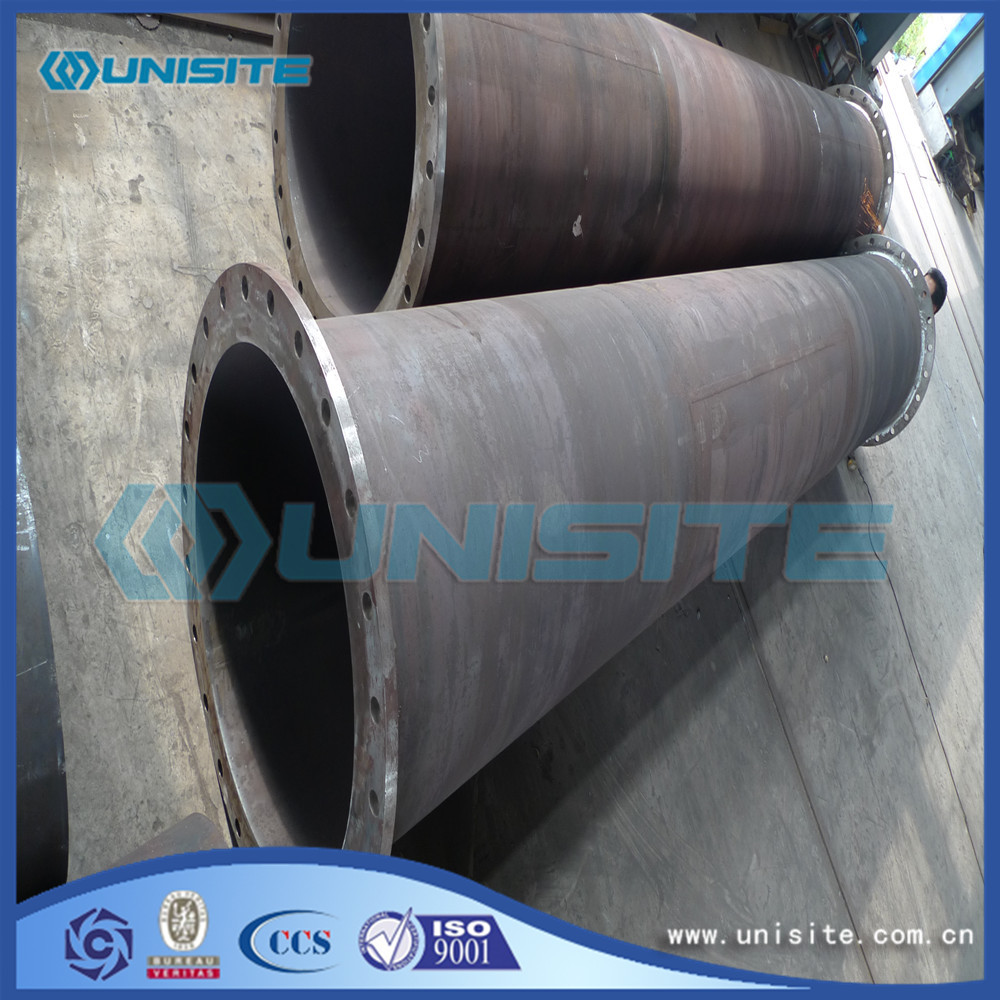

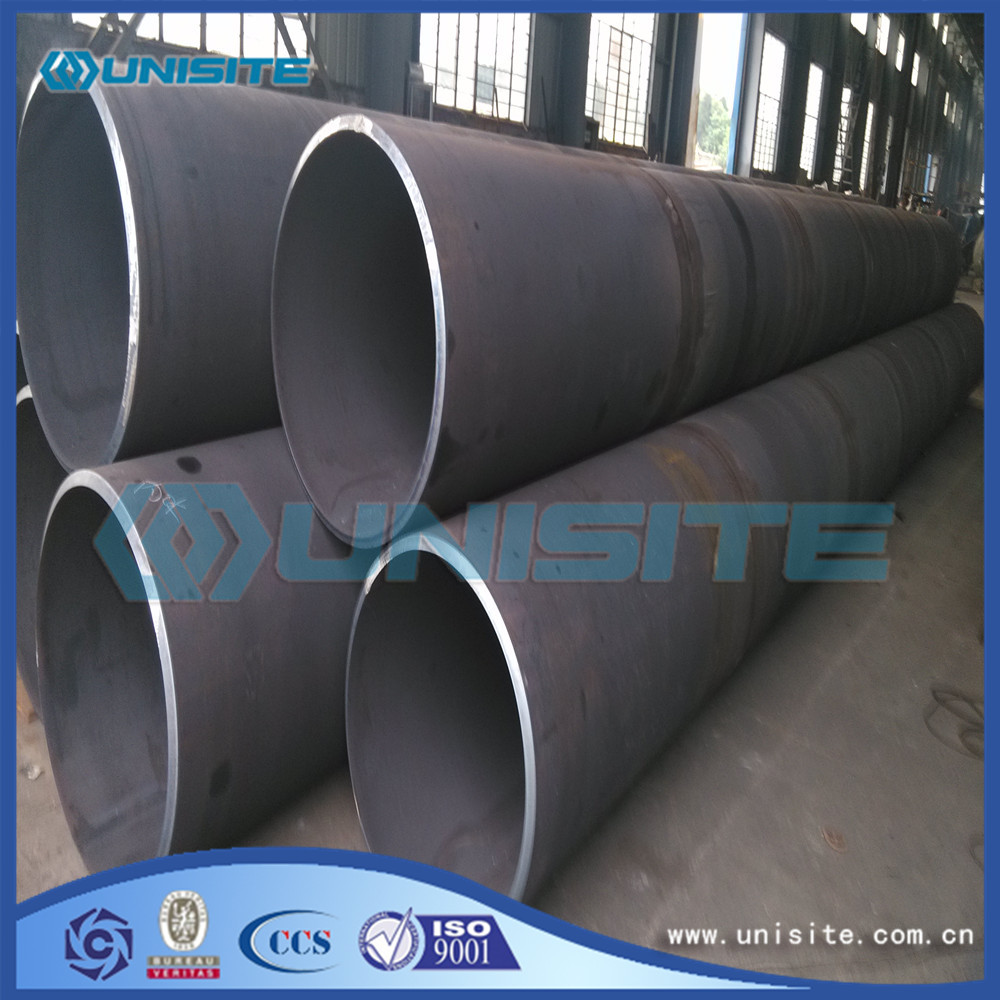

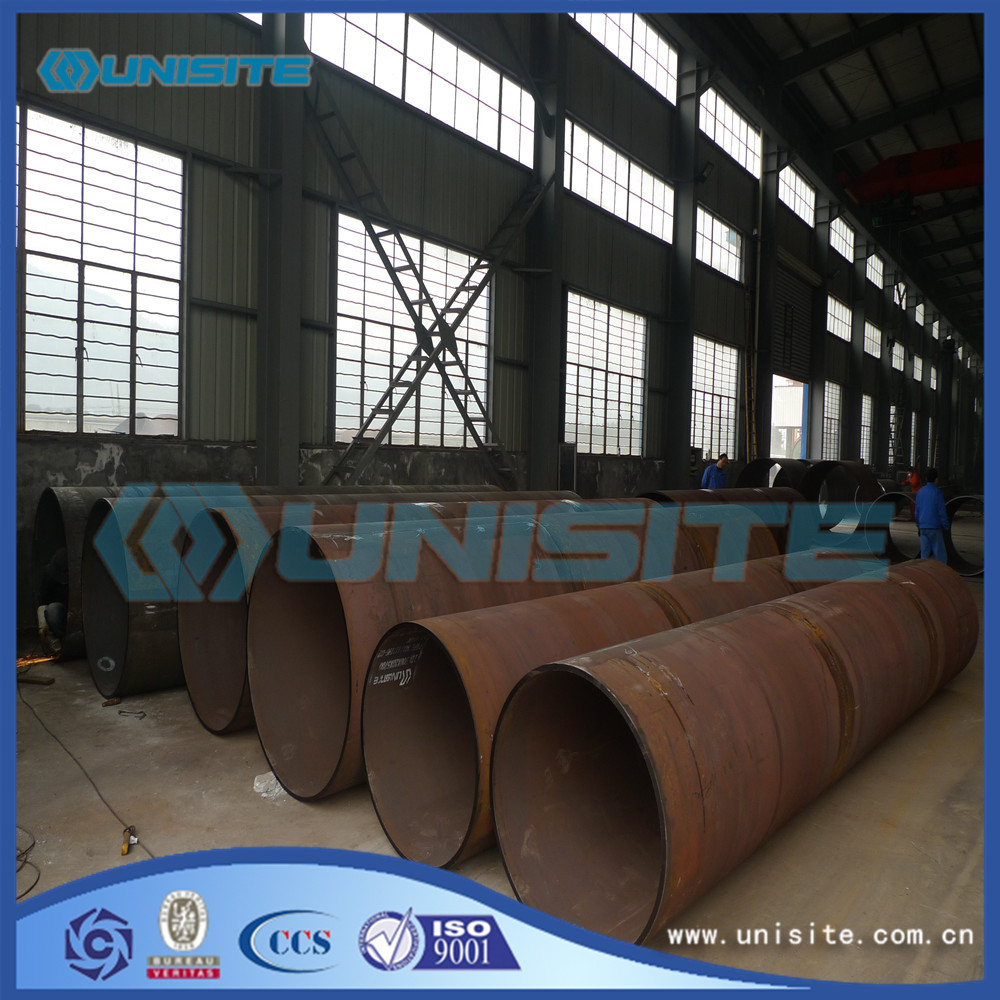

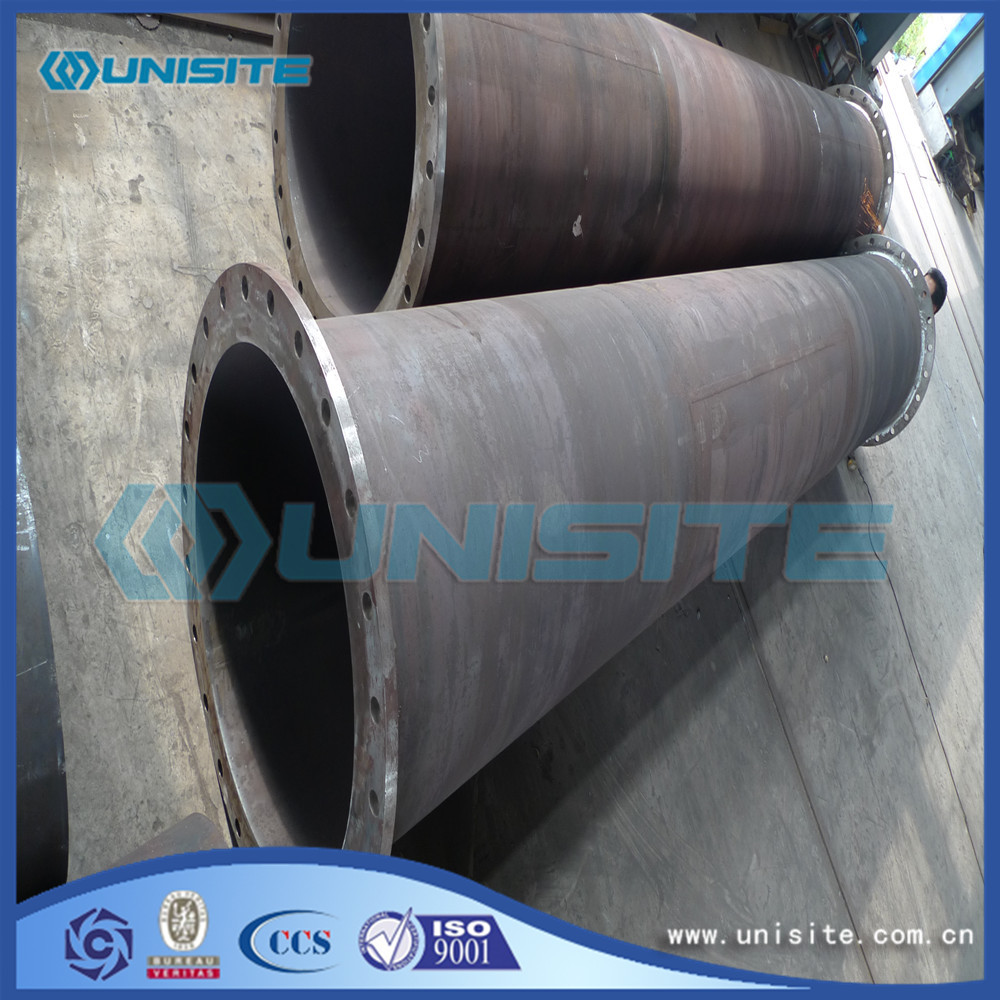

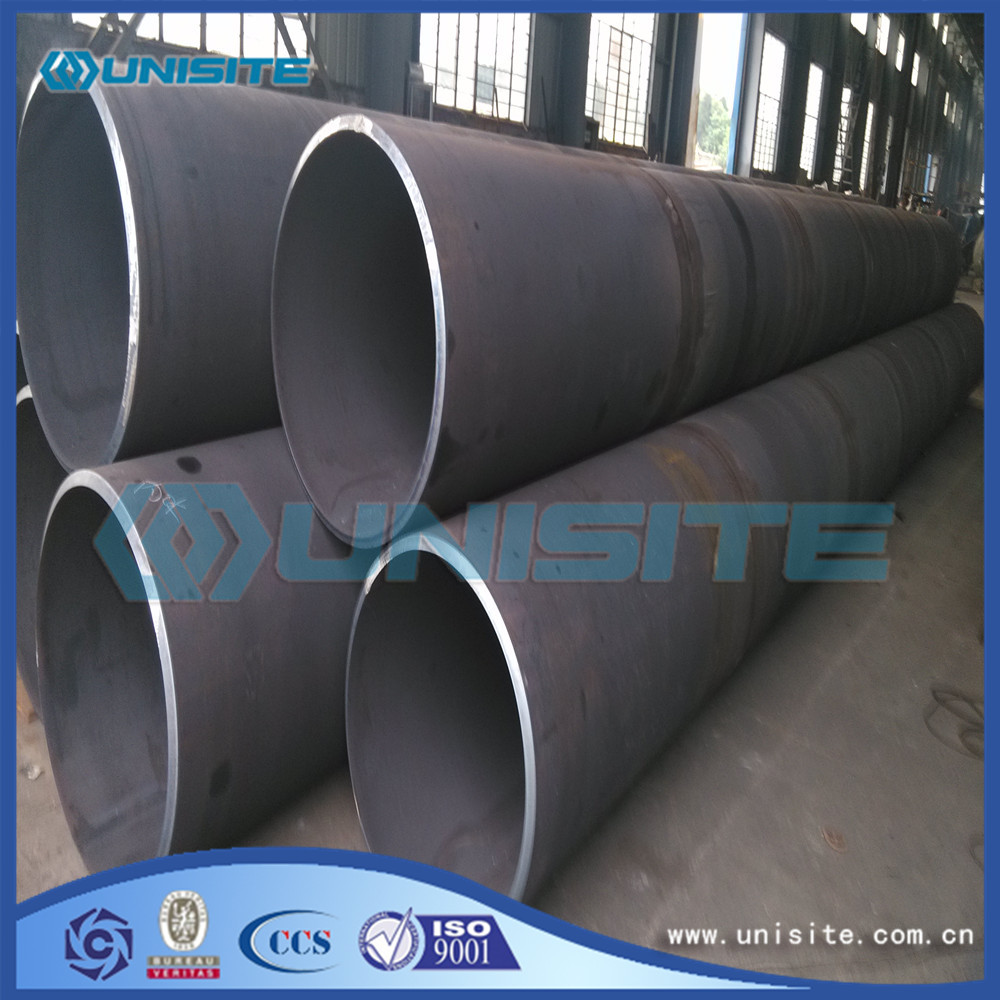

Photos of our Longitudinally Welded straight steel pipes saw

We have a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

You can see the quality of all our previous orders were guaranteed based on our good procedure and service.

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Saw Pipe