SAW filler material usually is a standard wire as well as other special forms. This wire normally has a thickness of 1.6 mm to 6 mm (1/16 in. to 1/4 in.). In certain circumstances, twisted wire can be used to give the arc an oscillating movement. This helps fuse the toe of the weld to the base metal. The electrode composition depends upon the material being welded. Alloying elements may be added in the electrodes. Electrodes are available to weld mild steels, high carbon steels, low and special alloy steels, stainless steel and some of the nonferrous of copper and nickel. Electrodes are generally copper coated to prevent rusting and to increase their electrical conductivity. Electrodes are available in straight lengths and coils. Their diameters may be 1.6, 2.0, 2.4, 3, 4.0, 4.8, and 6.4 mm. The approximate value of currents to weld with 1.6, 3.2 and 6.4 mm diameter electrodes are 150–350, 250–800 and 650–1350 Amps respectively.

Advantages of Saw Pipe

High deposition rates (over 45 kg/h (100 lb/h) have been reported).

High operating factors in mechanized applications.

Deep weld penetration.

Sound welds are readily made (with good process design and control).

High speed welding of thin sheet steels up to 5 m/min (16 ft/min) is possible.

Minimal welding fume or arc light is emitted.

Practically no edge preparation is necessary depending on joint configuration and required penetration.

The process is suitable for both indoor and outdoor works.

Welds produced are sound, uniform, ductile, corrosion resistant and have good impact value.

Single pass welds can be made in thick plates with normal equipment.

The arc is always covered under a blanket of flux, thus there is no chance of spatter of weld.

50% to 90% of the flux is recoverable, recycled and reused.

Advantages of UniSite

(1) No customer quality complaints for 10years

We have a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

You can see the quality of all our previous orders were guaranteed based on our good procedure and service.

(2) Born from military factory, with rigorous team having rich experience of military marine products

We UniSite started as a small contractor of ship building works in military factory in Ningbo 10 years ago. After several years of accumulation, the team had owned a certain number of experienced managers, engineers, technicians and workers who have rich experience in military shipping building and have good marine practice.

(3) Involved in many big projects all over the world

We have involved in many projects all over the world that we have ability to participate in big projects.

(4) BV/CCS approval for manufacturer capability qualification

We passed the BV/CCS approval for manufacturer capability qualification for dredging & Dredger products.

Our service Besides above the general specifications, we can also supply some specific pipes and other similar steel structure as clients' requirements.

Package and shipping bulk package and bulk vessel transportation

frame container package and frame container transportation

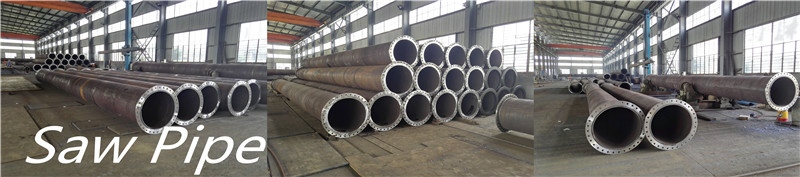

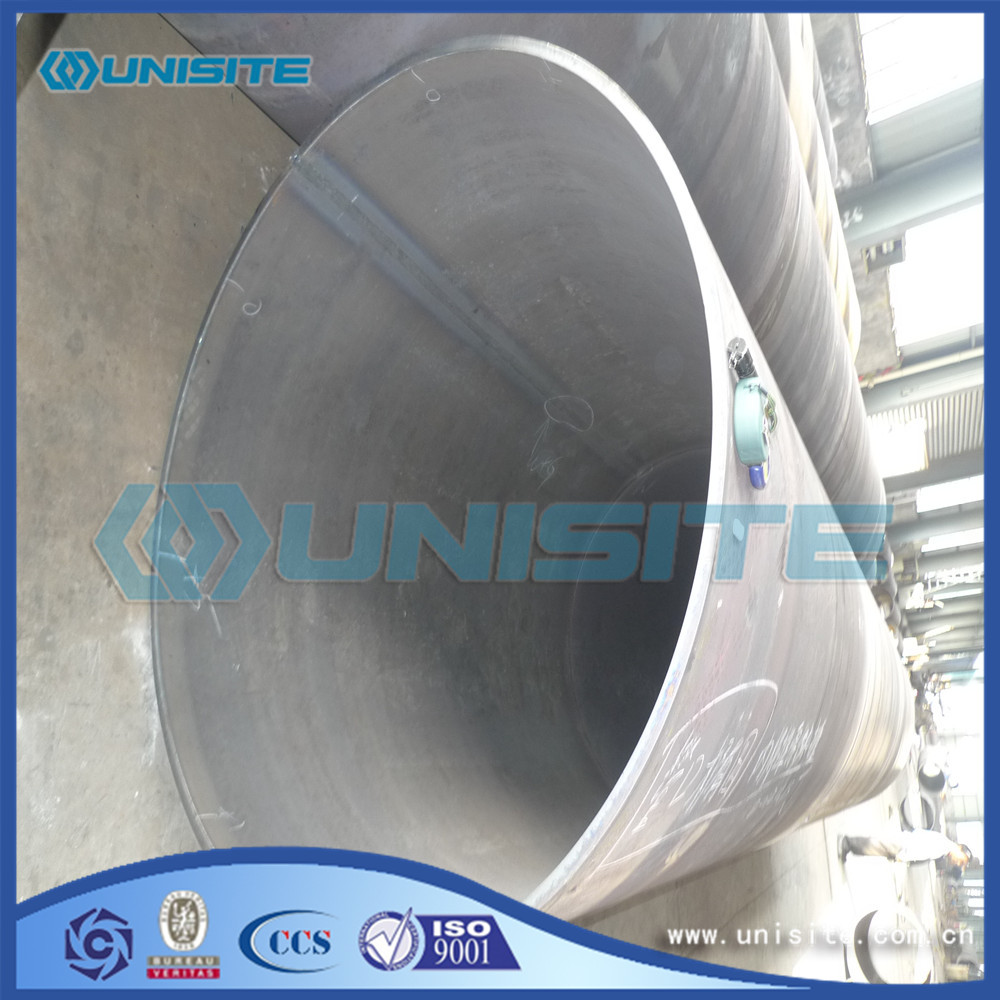

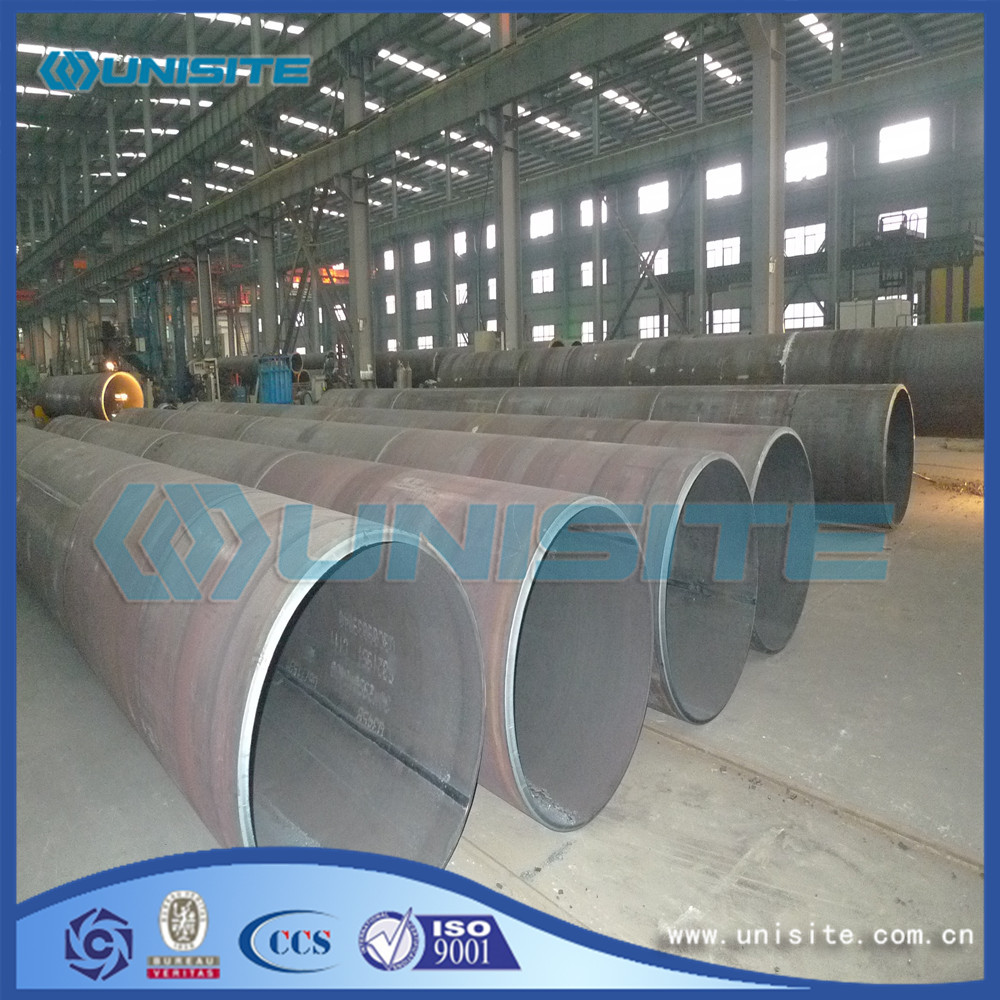

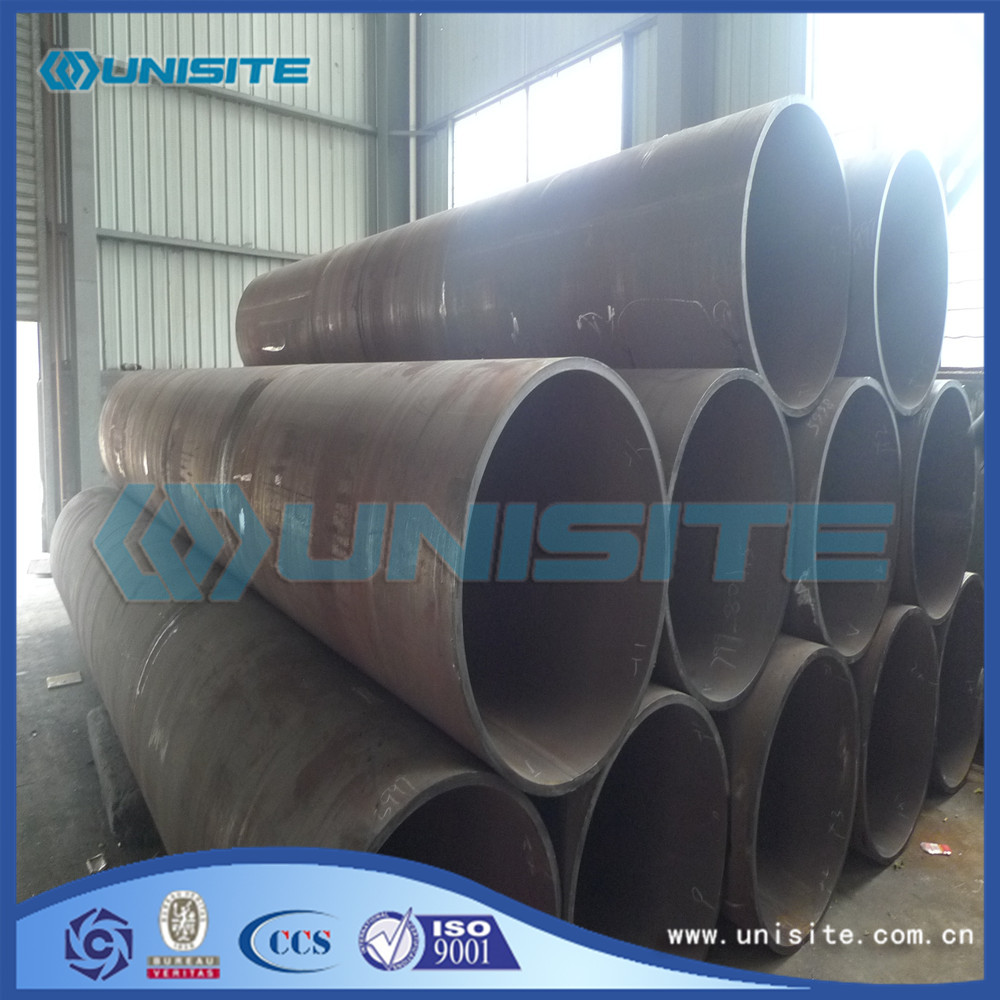

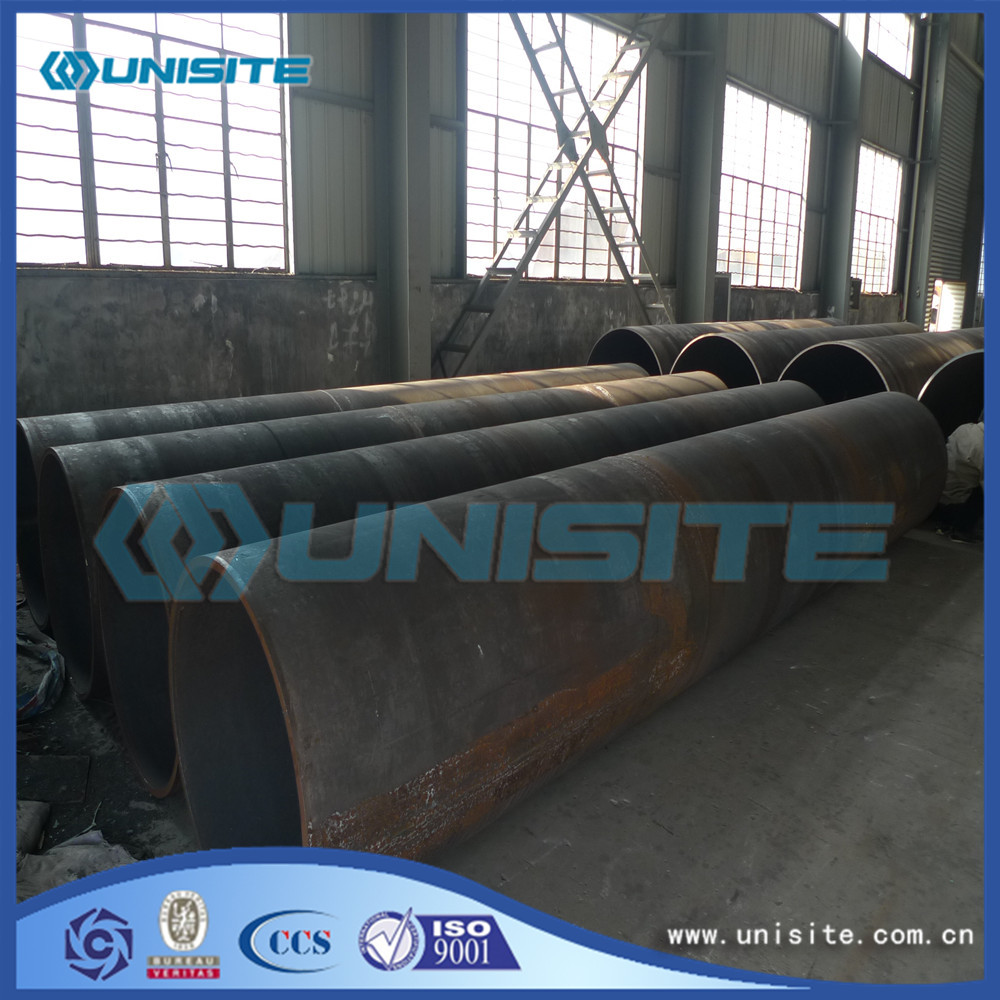

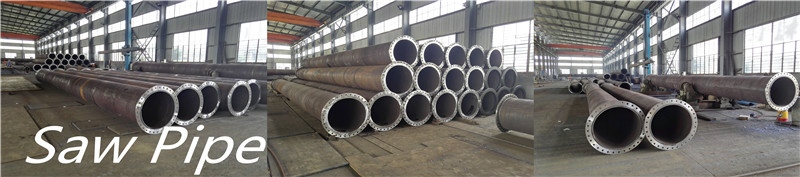

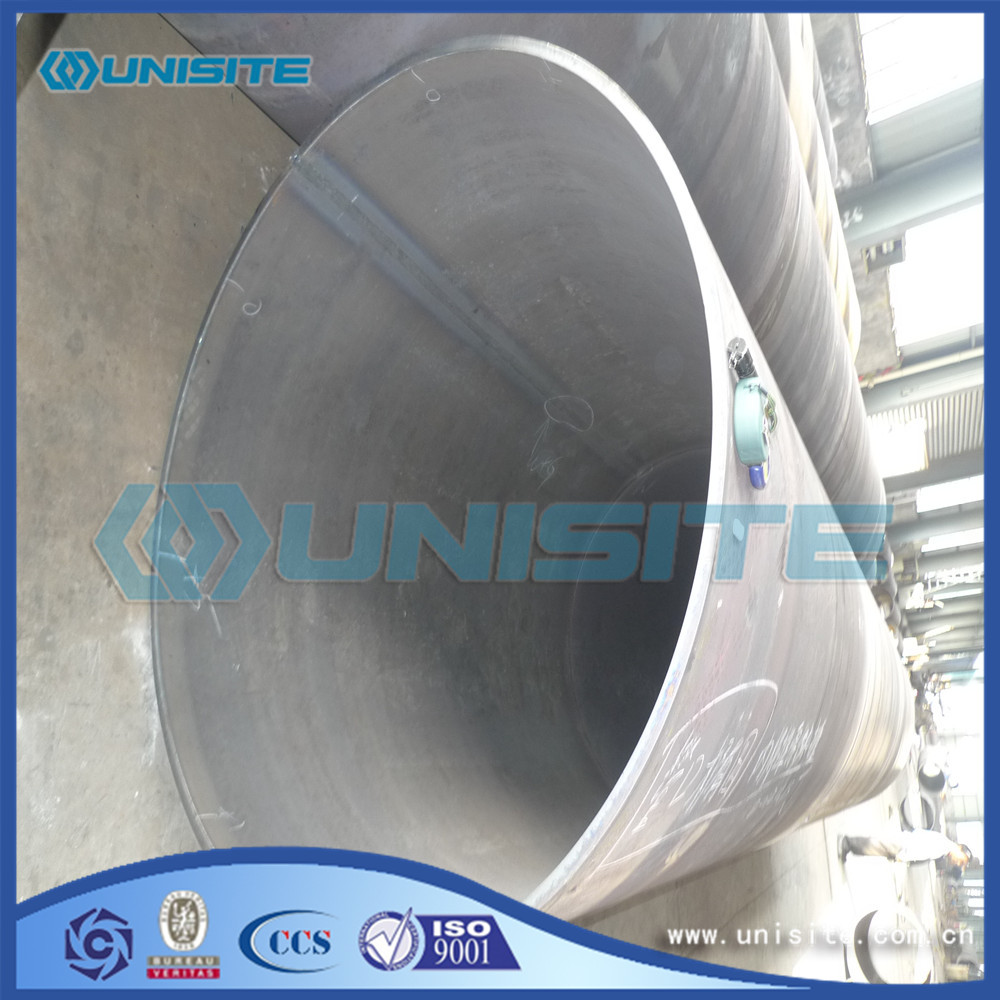

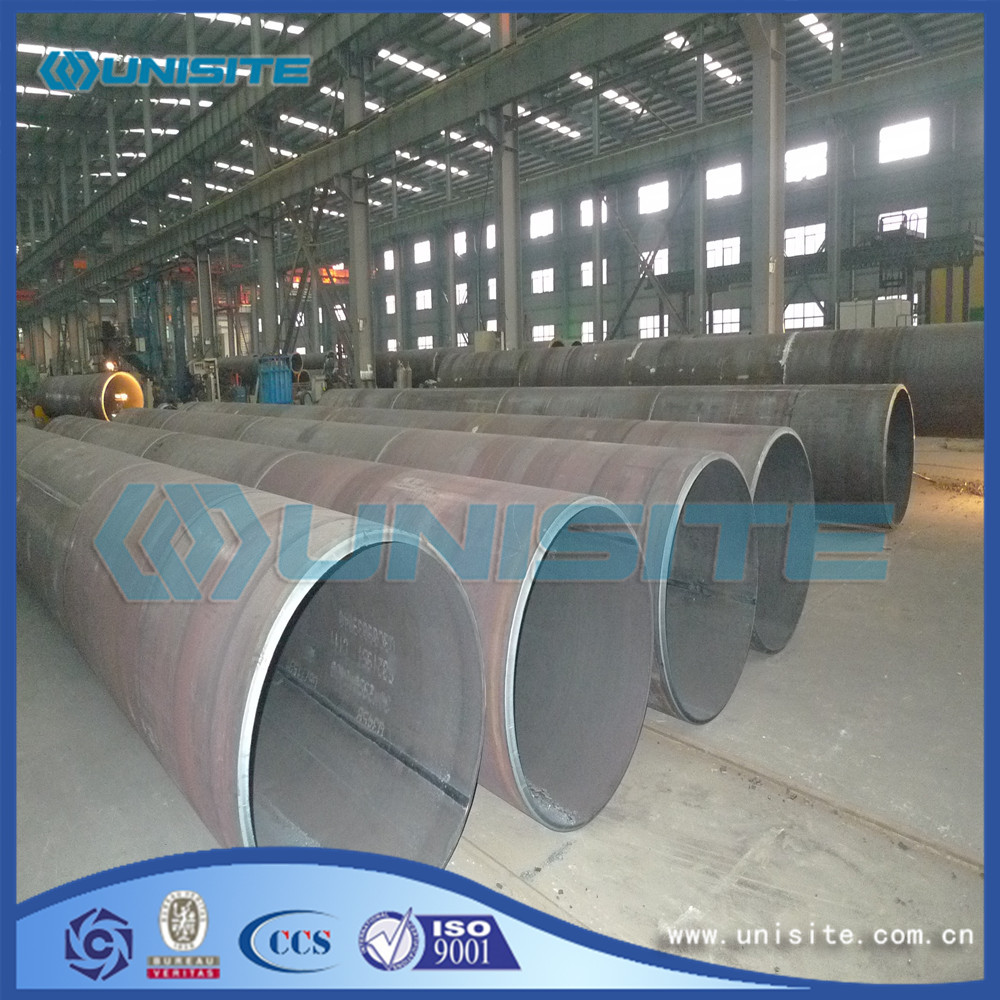

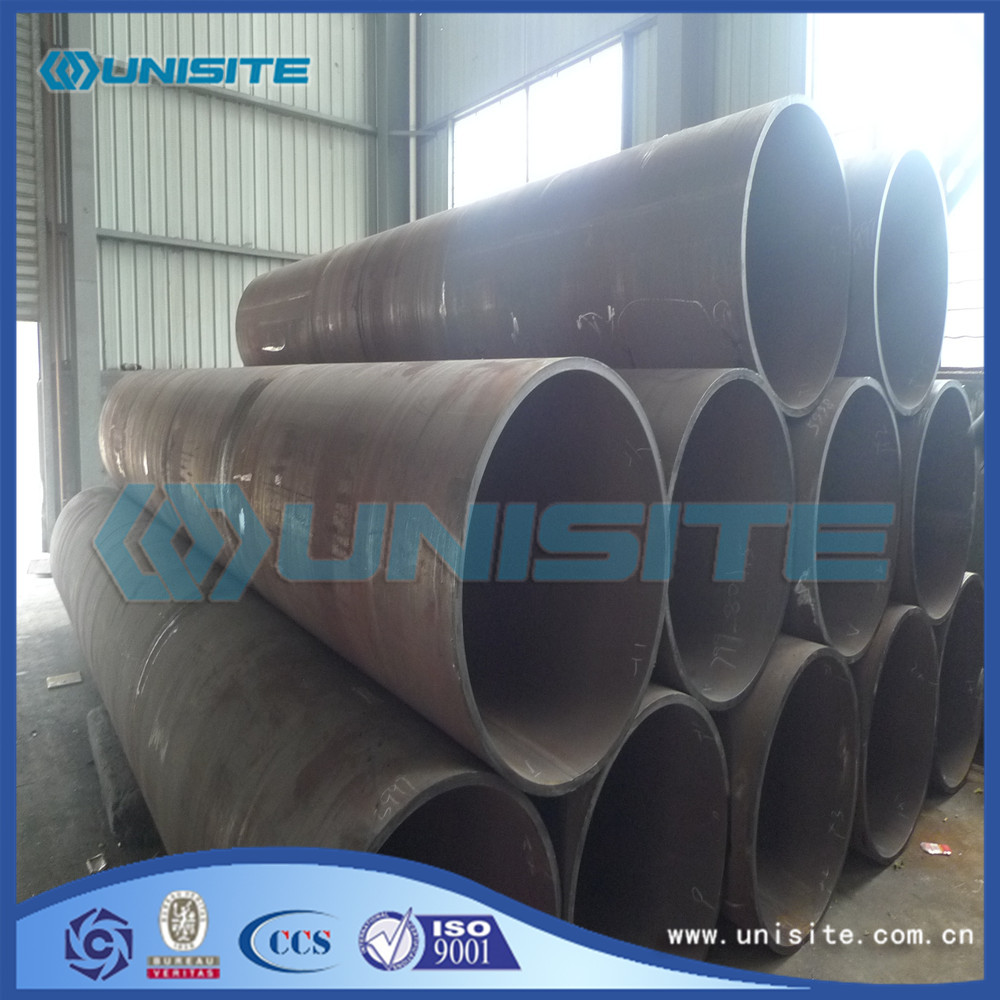

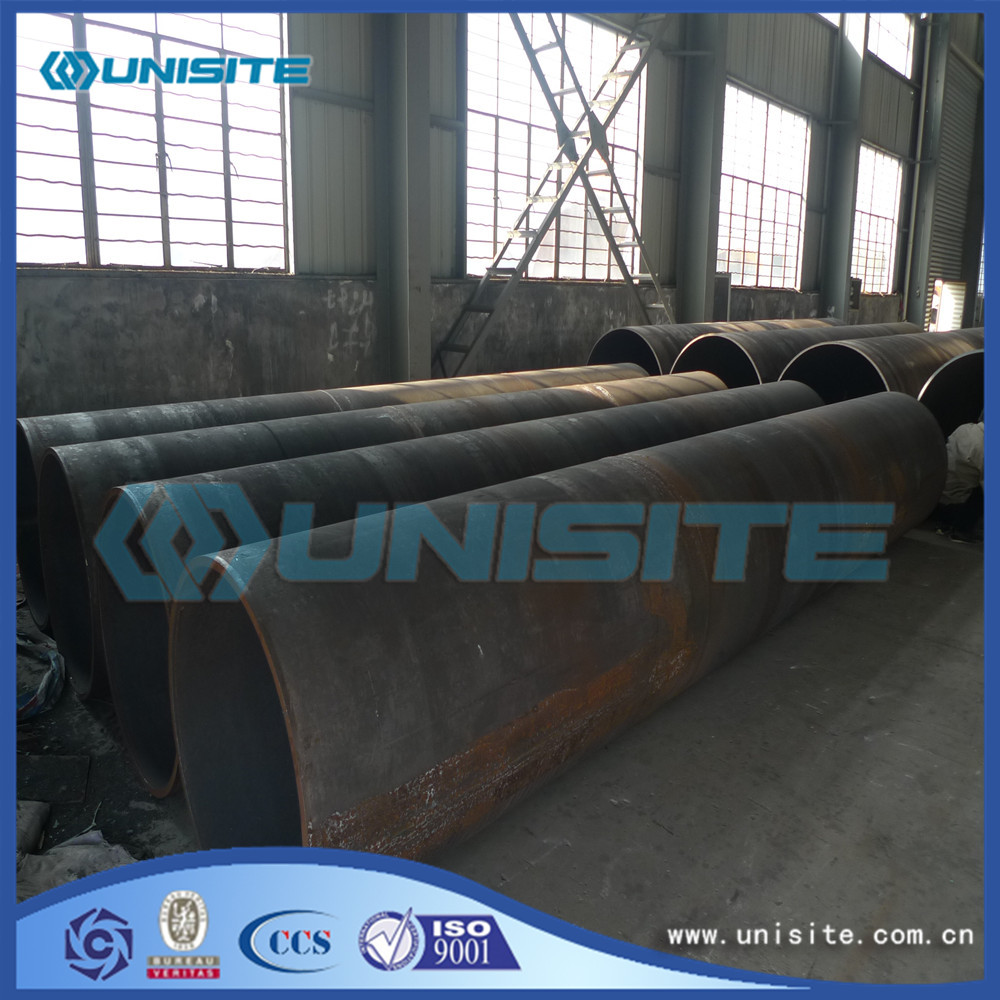

Photos of our Weld saw carbon steel pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Steel Pipe > Saw Pipe