Company Details

Unisite Group Ltd.

- [Zhejiang,China]

- Business Type:Manufacturer , Trade Company

- Main Markets: Middle East , West Europe , Americas , Asia , East Europe , Europe , North Europe , Oceania , Worldwide

- Exporter:91% - 100%

- Certs:ISO9001

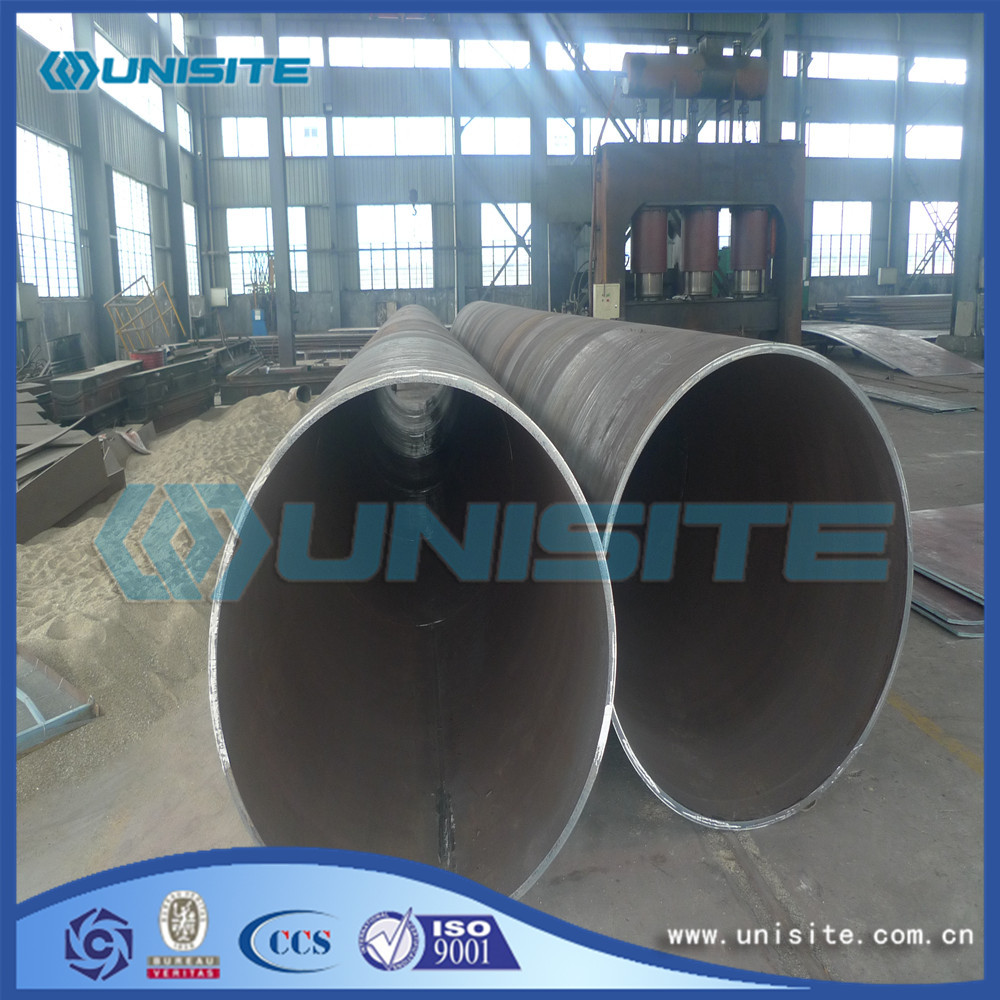

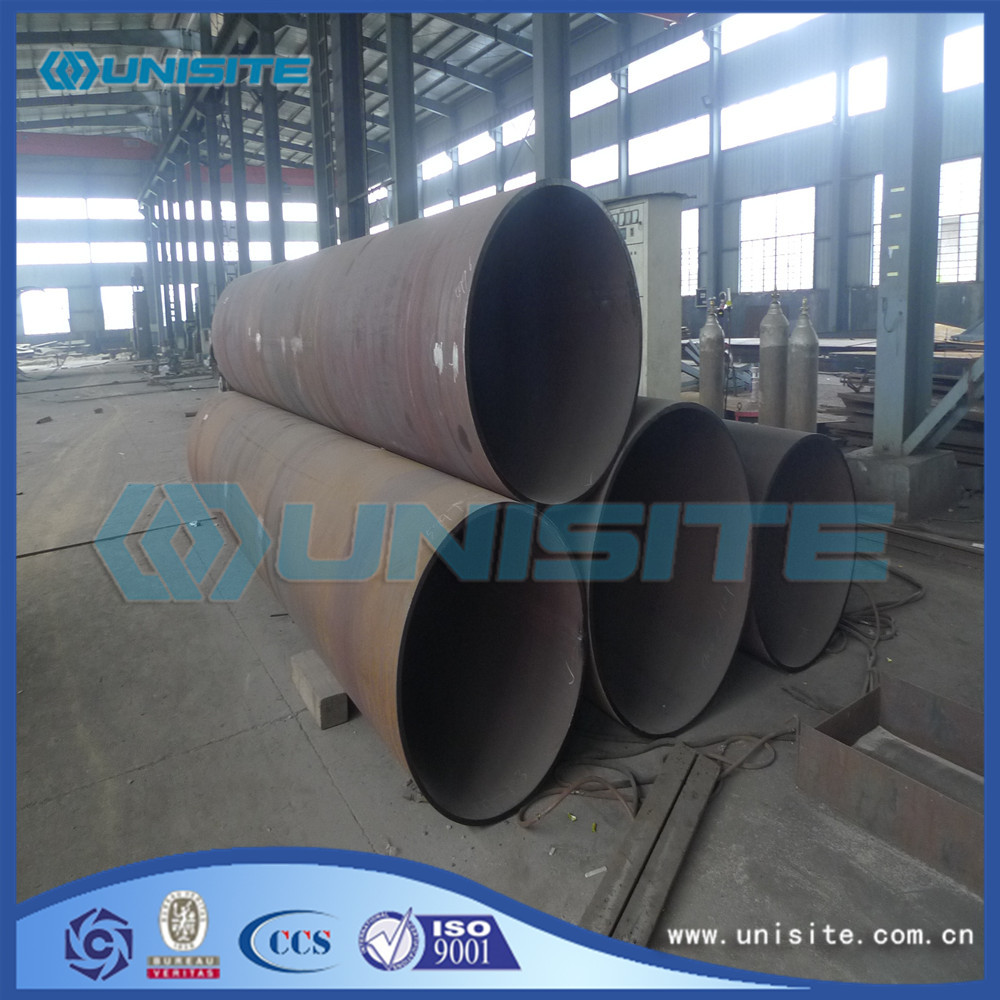

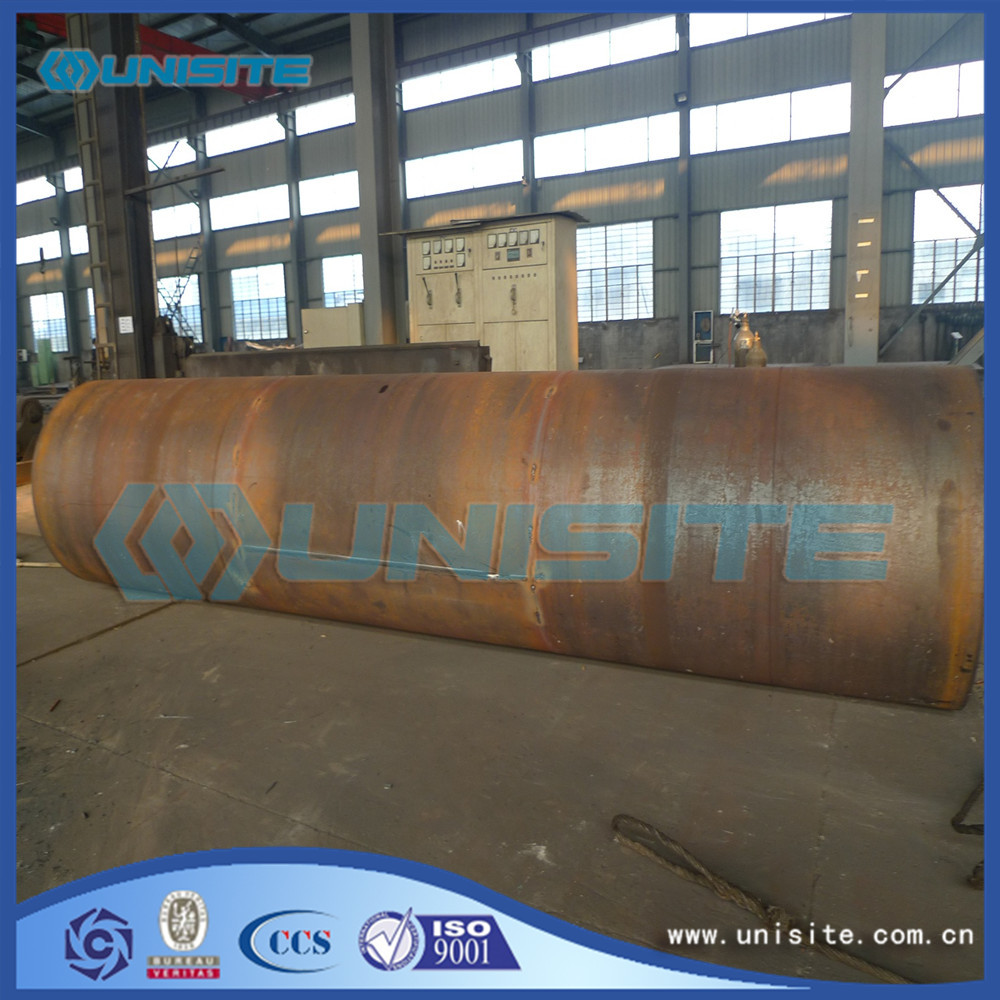

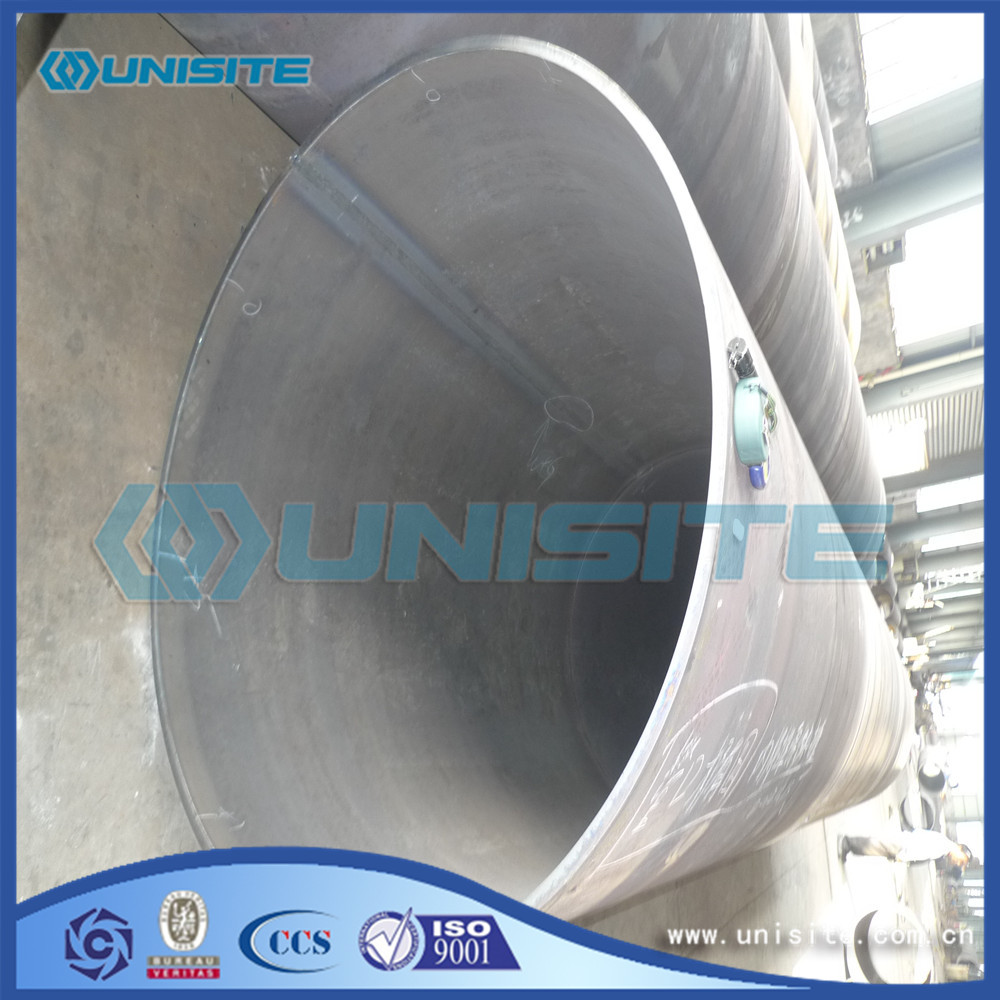

- Description:Longitudinal Saw Welded Pipe,Saw Welded Carbon Steel Pipes,Steel Carbon Saw Welded Pipes