Slurry Pump is a broad pump a common concept, different geographical, habits, ultimately relates to the pump will be as. This entry describes the mud pump is the most of a pump, oil field drilling. The application of mud pump. In fact, the sewage pump, slurry pump and other non water pump and slurry pump also has a common name in. This entry is to the reader of the drilling mud pump.

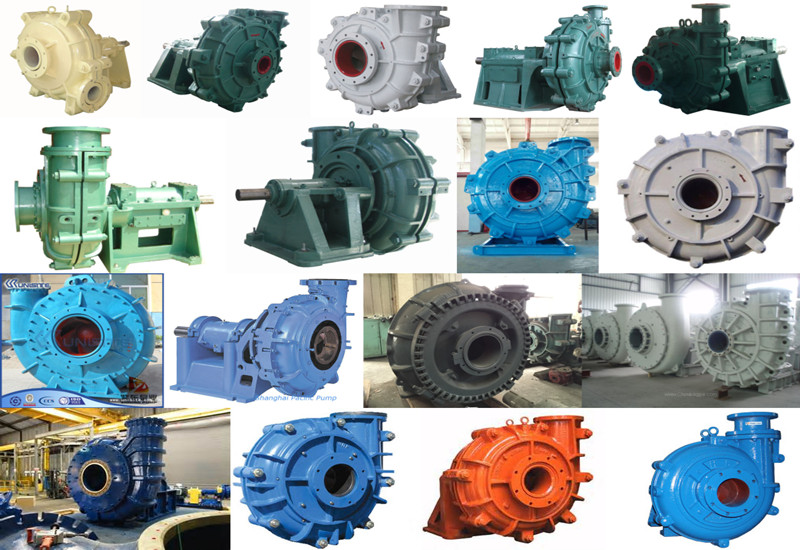

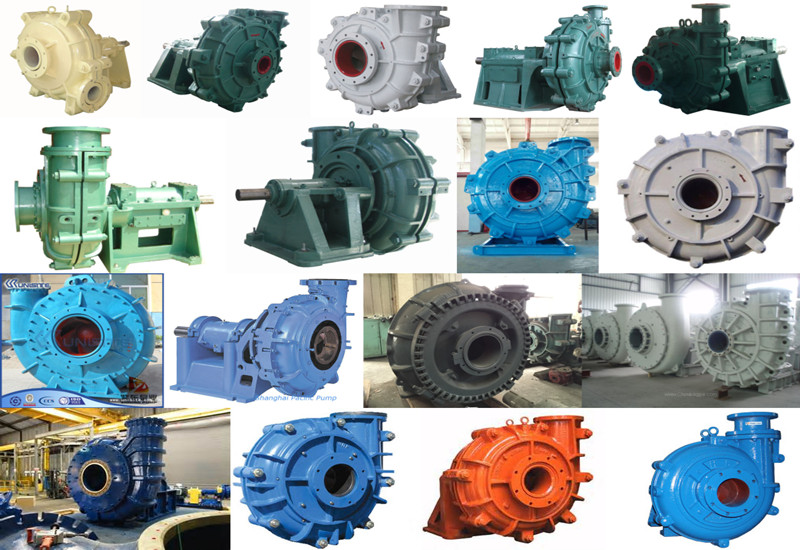

Photo of our Slurry Pump:

Summary

Mud pump, refers to the process of drilling in the drilling fluid to transport mud or water, such as washing fluid machinery. Mud pump is an important part of drilling equipment.

In the commonly used positive circulation drilling, it is the surface flushing medium - water, polymer mud or flushing fluid under pressure, through the high pressure hose, faucet and pipe column center hole sent straight drill bit at the bottom of the to to cool drill, cutting down the debris cleared and transported to the surface.

Common mud pump is a piston or plunger, by the power machine drives the crankshaft rotary pump crankshaft through the crosshead drive piston in the pump cylinder for reciprocating motion. Under the alternating action of the suction and the discharge valve, the purpose of the pressure feed and the circulating flushing liquid is realized.

classification

According to function

Single acting mud pump

In one cycle of the reciprocating motion of the piston, only one suction and drainage action is completed.

Double action type mud pump

In a cycle of reciprocating motion of the piston to complete the two suction and drainage action

pressure

Pump pressure depends on the depth of the hole, flushing fluid through the resistance of the channel and the nature of the transport of flushing fluid, etc.. The deeper the drill hole, the greater the resistance of the pipeline, the higher the pressure required.

With the change of the diameter and depth of the hole, the displacement of the pump can be adjusted at any time. A gear box or a hydraulic motor is arranged in the mechanism of the pump to adjust the speed of the hydraulic motor to achieve the purpose of changing the displacement. In order to accurately grasp the changes in the pump pressure and displacement, the mud pump to install flow meter and pressure gauge, and at any time so that staff understand the drilling pump delivery \ turn, while the pressure changes discriminant hole condition is normal in order to prevent the occurrence of accidents in the hole.

Product features

1, can transport high concentration and high viscosity <10000PaS and containing particles of suspended slurry.

2, conveying fluid flow stability, no flow, pulsation and mixing, shear slurry phenomenon.

3, discharge pressure and speed has nothing to do, low flow can also maintain a high discharge pressure.

4, the flow rate is proportional to the speed, through the variable speed mechanism or variable speed motor can realize the flow regulation.

5, self-priming ability, without bottom valve can be directly sucked liquid.

6, the pump can be reversed, the flow of liquid by the direction of the rotation of the pump to change, apply to the pipeline to reverse the direction of the occasion.

7, smooth operation, vibration, noise.

8, simple structure, easy disassembly and assembly.

Type I-1B pump concentration is widely used in chemical, pharmaceutical, brewing, papermaking, food etc..

Attention component

The liner of mud pump, mud pump, cylinder head, cylinder top sleeve rod,

Piston, piston plate, cup, piston, piston rod, piston rod, inlet and outlet valve, inlet and outlet valve seat, crosshead, crosshead sliding sleeve, crosshead pin shaft, crankshaft, connecting rod, connecting rod under the tile, connecting rod copper sets, connecting rod screw, a nut, a crown nut, skeleton oil seals, O - sealing ring, bearing and matching of gear, shaft etc. easily a quality problem, should be paid attention to in the purchase and use.

Matters needing attention

Before starting the mud pump, check the water inlet pipe, a water outlet pipe is blocked, from front to rear bearing grease filling, check the packing is full. Mud pump should be equipped with high-pressure water pump, will be greater than the pressure of slurry pump fresh water input to the leak proof packing, packing for protection, mud pump is not close flush pump. Otherwise, it will make rapid wear of seal parts. The gap between the Impeller and the guard board is reasonable, which has a great influence on the life of the mud pump. Clearance is unreasonable, pump running produce vibration and noise, over-current damage to parts quickly, and replacing the impeller, should pay attention to the gap to meet the requirements of the drawings, to adjust the clearance, the rear axle bearing body by the adjustment screw to. Mud pump allows the suction process is in the transport of water when the determination of the slurry should be taken into account the impact of mud on the suction capacity.