Slurry pumps are widely used to transport corrosive/abrasive and high concentration slurry in many industries such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include Molybdenum, Electric Utilities, Oil Shale, Water & Sewage Utilities, Building areas, Sand & Gravel, Tobacco and Agriculture (hog, poultry, dairy manure).

What is the specifications of our Slurry Pump

A. General

We have developed our USSP dredge pumps, which are used in the metallurgy, mines, coal and power area and deliver slurry with strong abrasion high concentration. These series of dredge pumps have characteristic features: High efficiency, wear resistant, stable performance, interchangeability of parts.

B. Structure and Feature

These type of pumps have double casing structure.

Outer casing, split outer casing halves that made of cast or ductile iron with the wear liners and provide high operation pressure capabilities.

The lining and Impeller can be made of wear metal or rubber. Deep side sealing vanes relieve can seal pressure and minimize recirculation.

The discharge outlet can be adjusted with rotation interval of 45 degree, the pumps can be operated in series and driven with belt.

Hard metal liners are tapered to make sure precise alignment during assembly and allow components to be easily removed for replacement.

C. Series and types

Surry pump including high heavy duty slurry pump(series USSPH), light heavy duty slurry pump(series USSPL), slurry gravel pump(series USSPG), sump pump(series USSPS), froth pump(series USSPF)

D. Materials

All fabricated casting used in the construction of the pump will be to manufacturing standard of UniSite or other classification society.

All materials normally are high-chromium white cast iron with our standard material sheet, but not limited for other specified material from client.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

E. Technology

We use CFD (Computational Fluid Dynamics) technology to predict the internal flow path and flow field and external property of pump, to analog the movement of slurry in pump, to adjust the wrap angle and thickness of impellers.

We use CAE that adopts the advanced value solving approach, which can analyze the complex actual flow forming and analog the process, predict the possible defects such as shrinkage cavity, coiling air and ash, advise the effective measurement for improve the technology, decrease the rejection rate.

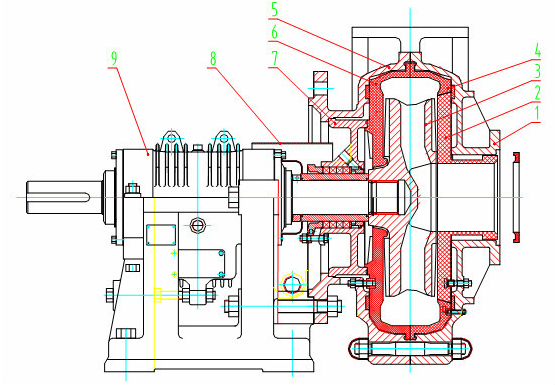

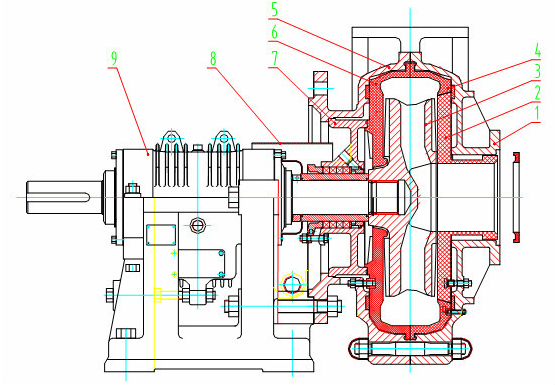

Schematic diagram of the structure

Rubber Liner slurry pump:

| NO | Description | Material |

| 1 | Pump Cover | QT500-7 |

| 2 | cover plate | rubber+Q235B |

| 3 | Impeller | rubber+QT500-7 |

| 4 | cover plate liner | rubber+Q235B |

| 5 | pump casting | QT500-7 |

| 6 | flange plate liner | rubber+Q235B |

| 7 | Stuffing box | rubber+T200 |

| 8 | Waterproof cover | 1Cr18Ni9Ti |

| 9 | Bracket | Q235B

|

Photos of our Marine steel centrifugal slurry pumps

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Pump And Spare Parts > Slurry Pump