A Slurry Pump is a type of centrifugal pump, lobe pump or peristaltic hose pump in physics principle that increases the pressure of liquid and solid particle mixture (aka slurry), through centrifugal force (a rotating Impeller) and converts electrical energy into slurry potential and kinetic energy.

Components of slurry pump

A. Impeller

The impeller, either elastomer or high-chrome material, is the main rotating component which normally has vanes to impart the centrifugal force to the liquid.

B. Casing

Split outer casing halves of cast contain the wear liners and provide high operation pressure capabilities. The casing shape is generally of semi-volute or concentric, efficiencies of which are less than that of the volute type.

C. Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy-duty roller bearing are housed in a removable bearing cartridge.

D. Shaft sleeve

A hardened, heavy-duty corrosion-resistant sleeve with O-ring seals at both ends protects the shaft. A split fit allows the sleeve removed or installed quickly.

E. Shaft Seal

Expeller drive seal, Packing seal, Mechanical seal.

F. Drive Type

V-belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices

Slurry pumps are widely used to transport corrosive/abrasive and high concentration slurry in many industries such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include Molybdenum, Electric Utilities, Oil Shale, Water & Sewage Utilities, Building areas, Sand & Gravel, Tobacco and Agriculture (hog, poultry, dairy manure) and are grouped by:

impeller quantity: single stage and multistage slurry pump

shaft position from the horizontal: horizontal and Vertical Slurry Pump

impeller suction way: single suction and double suction slurry pump

pump casing structure: solid casing, horizontal split-case, and vertical split-case slurry pump

The parameters determined before selecting an appropriate slurry pump include capacity, head, solids handling capacity, efficiency and power, speed and NPSH.

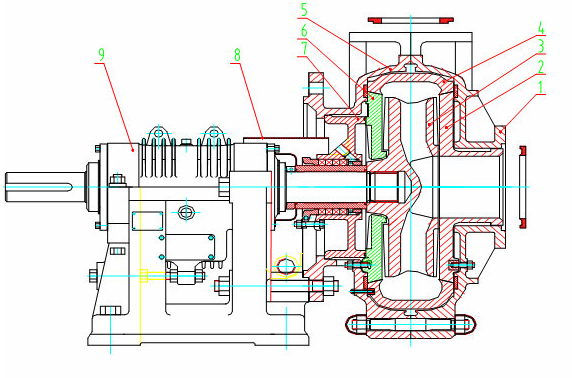

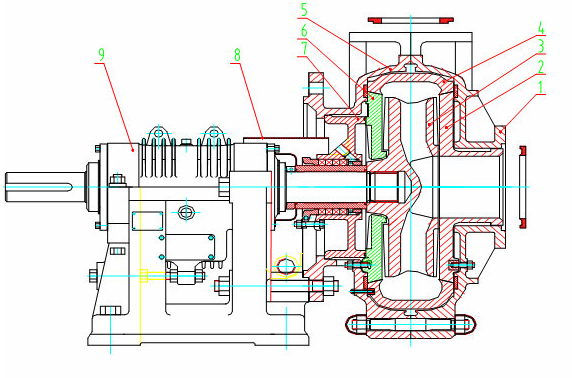

Schematic diagram of the structure

Metal Liner slurry pump:

| NO | Description | Material |

| 1 | Pump Cover | QT500-7 |

| 2 | cover plate | CAST IRON HARD |

| 3 | Impeller | CAST IRON HARD |

| 4 | cover plate liner | CAST IRON HARD |

| 5 | pump casting | QT500-7 |

| 6 | flange plate liner | CAST IRON HARD |

| 7 | Stuffing box | CAST IRON HARD |

| 8 | Waterproof cover | 1Cr18Ni9Ti |

| 9 | Bracket | Q235B |

Photos of our Steel marine slurry pumps

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Pump And Spare Parts > Slurry Pump