Stamping elbow points cold stamping and hot stamping two kinds, usually based on the properties of materials and equipment selection of cold stamping or hot stamping.Cold extrusion bend forming process is the use of special elbow forming machine, tube into the outer mold, mold clamping, under the push of tube billet reservation along the inner mould and the outer mould gap of movement and forming process.

Main particulars

| | MAIN PARTICULARS |

| Angle | Normal 5°, 10°, 15°, 22.5°, 30°, 45°, 60°, 90°or others acc. to order |

| Radius | 1D, 1.5D, 2D, 3D, 5D, 8D, 10D |

| Tolerance | High accuracy(ISO2768, ISO5817), within 2mm |

| Material | Carbon steel(likeS235JR~S345J2G3), stainless steel, alloy steel, etc. |

| Dimension(L*B*H) | As per drawing/order |

| Weight | 200KG~10000KG |

| Coating | Sa2.5 blasted and two or three layers painted with highest quality |

| Marking | as per clients' requirements |

| Inspection | material, construction, dimension, welding seam, non defective test, paint inspection |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Technological process

Seamless elbow: elbow is a kind of pipe fitting used for turning of pipe. In the pipeline system used in all the pipe fittings, the largest proportion, about 80%. In general, different forming processes are selected for different materials or wall thicknesses. At present, the factory used seamless elbow forming process, hot stamping, extrusion have.

Hot forming

Hot bend forming process is the special Elbow push processing machine, a core mold and a heating device, which makes in the mold blank in pushing mechanism driven by forward motion and in the movement is heating, expanding diameter and bending forming process. The deformation characteristics of the hot pushing elbow is based on the metal plastic deformation before and after constant volume law to determine the tube diameter, the tube diameter less than the diameter of the elbow, the through mandrel control the blank deformation process, the arc by the compression of the metal flow, compensation for expanding and other parts of the thin, in order to get uniform wall thickness of elbow.

The hot pushing elbow forming process has the advantages of beautiful appearance, uniform thickness and continuous operation, suitable for mass production. Therefore, it becomes the main processing method of carbon steel, alloy steel elbow, and is also used in some specifications of stainless steel elbow forming.

The heating method of forming process has the intermediate frequency or high-frequency induction heating (the heating coil can be multi circle or single ring), the flame heating and the reflection furnace heating.

Accessories of our bend

A. Main

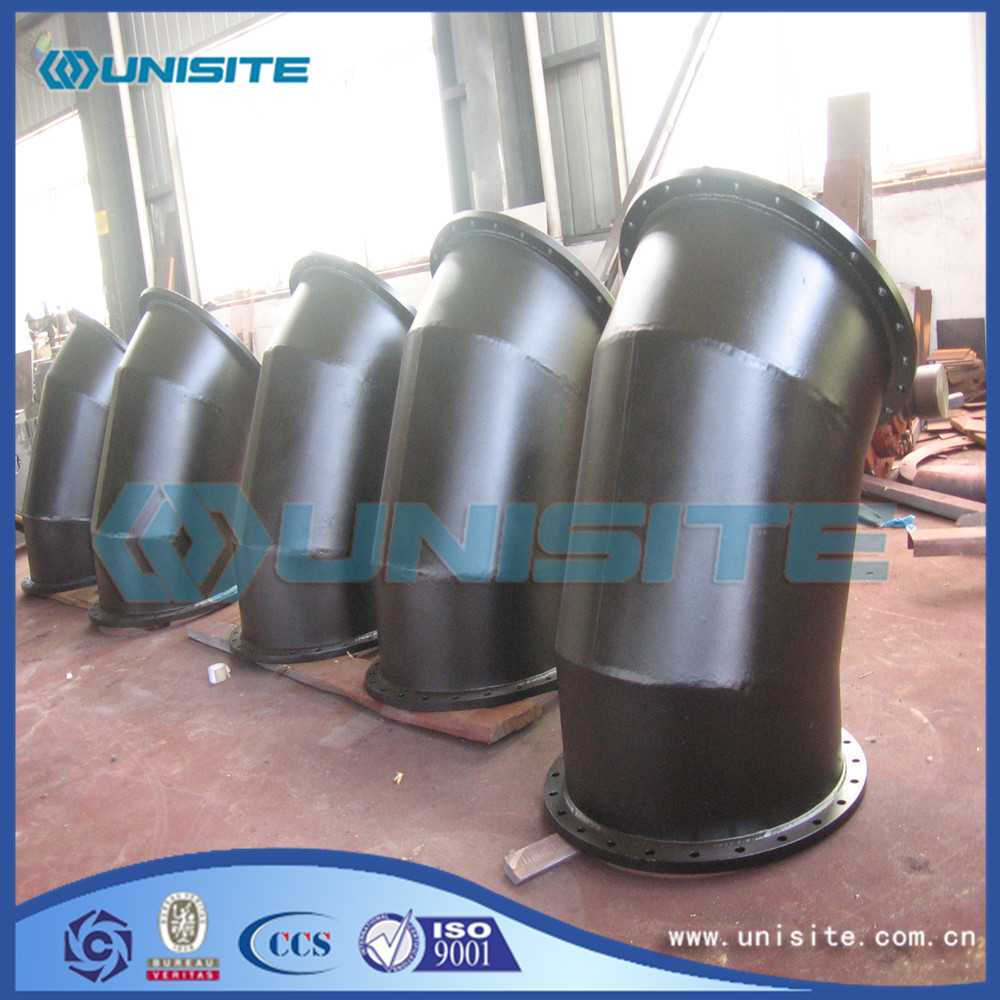

With flanges or without flanges

We can weld flanges with good quality.

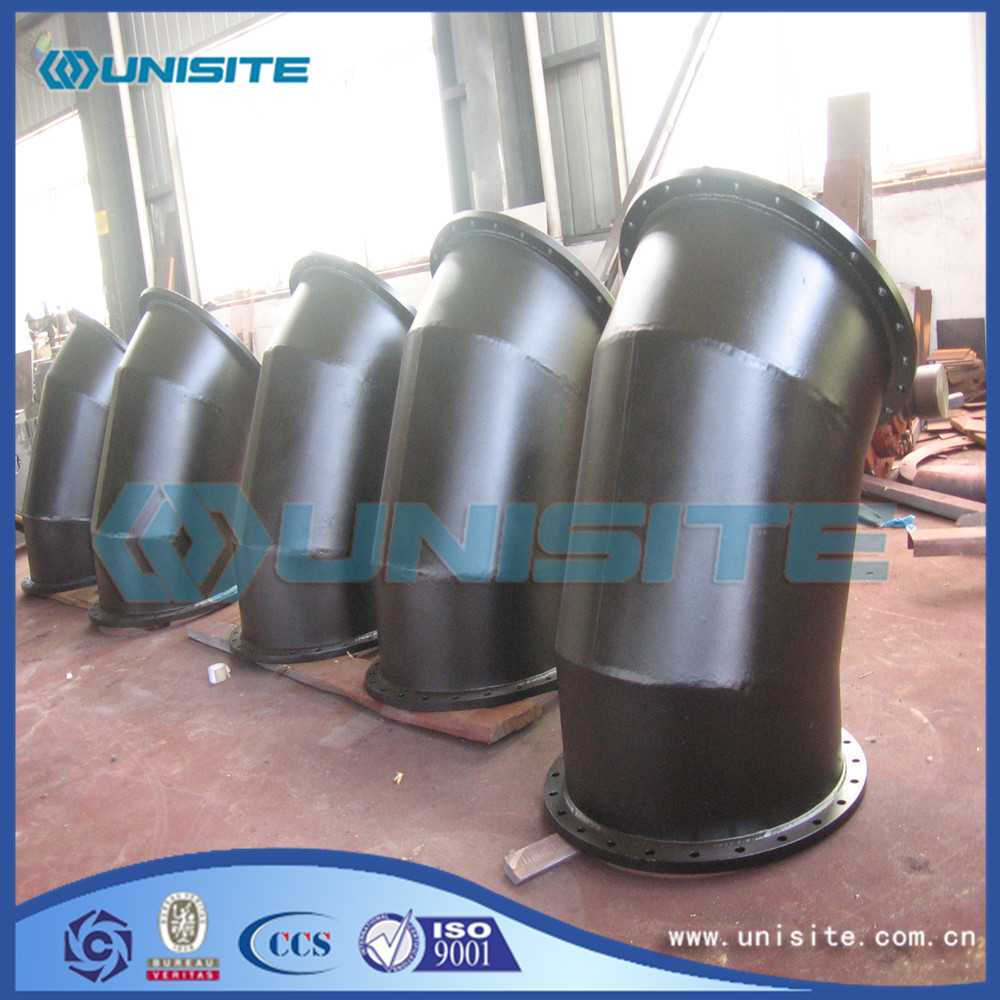

Photos of our Hot custom steel welded bends

Our service

Besides above the general specifications, we can also supply some specific bends and other similar steel structure as clients' requirements.

Package and shipping

Wooden Cases, Wooden Pallet or Neutral Boxes package and container transportation

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Pipe Bend > Welded Bend