Stamping elbow is the earliest application in mass production, the forming process of seamless elbow, at present, in the production of the elbow of the commonly used specifications has been hot pushingpipe method or other forming techniques of alternative, but in some specifications of elbow due to less number of production, wall thickness too thick or too thin.

The specifications of our bend

A. General

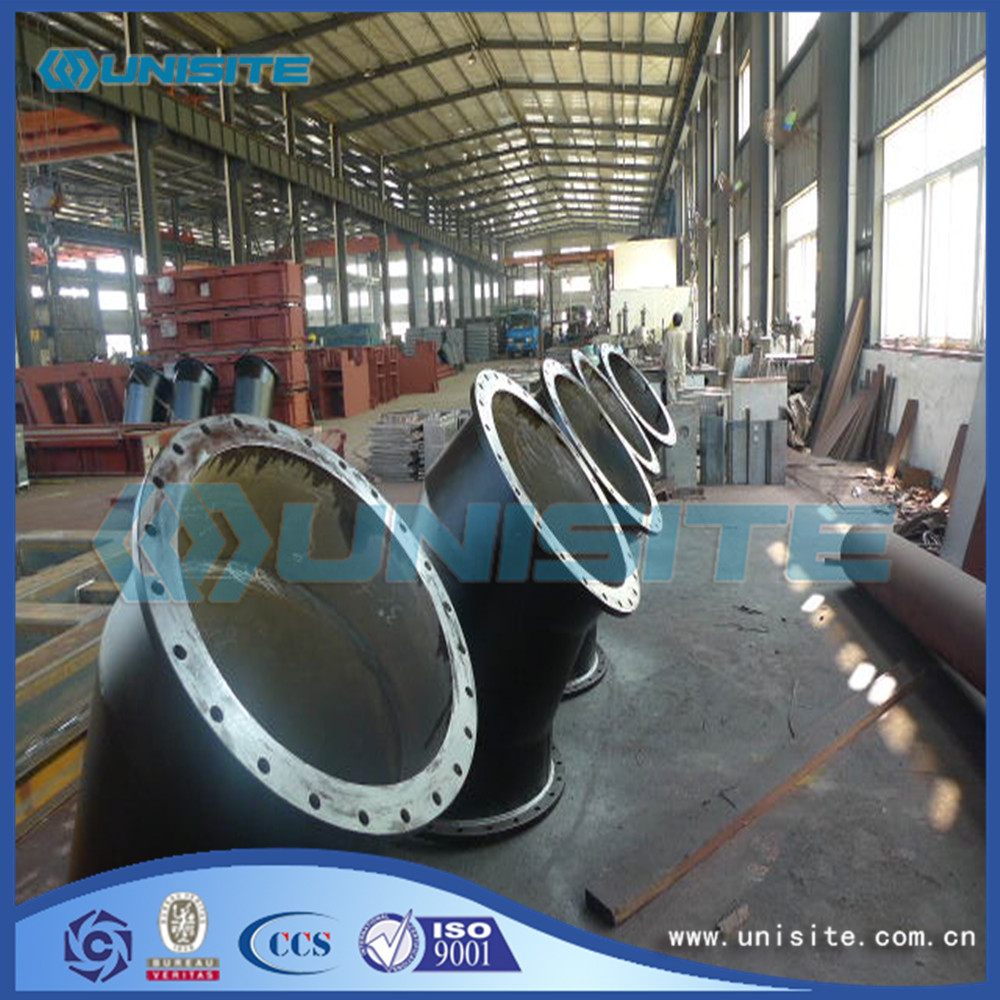

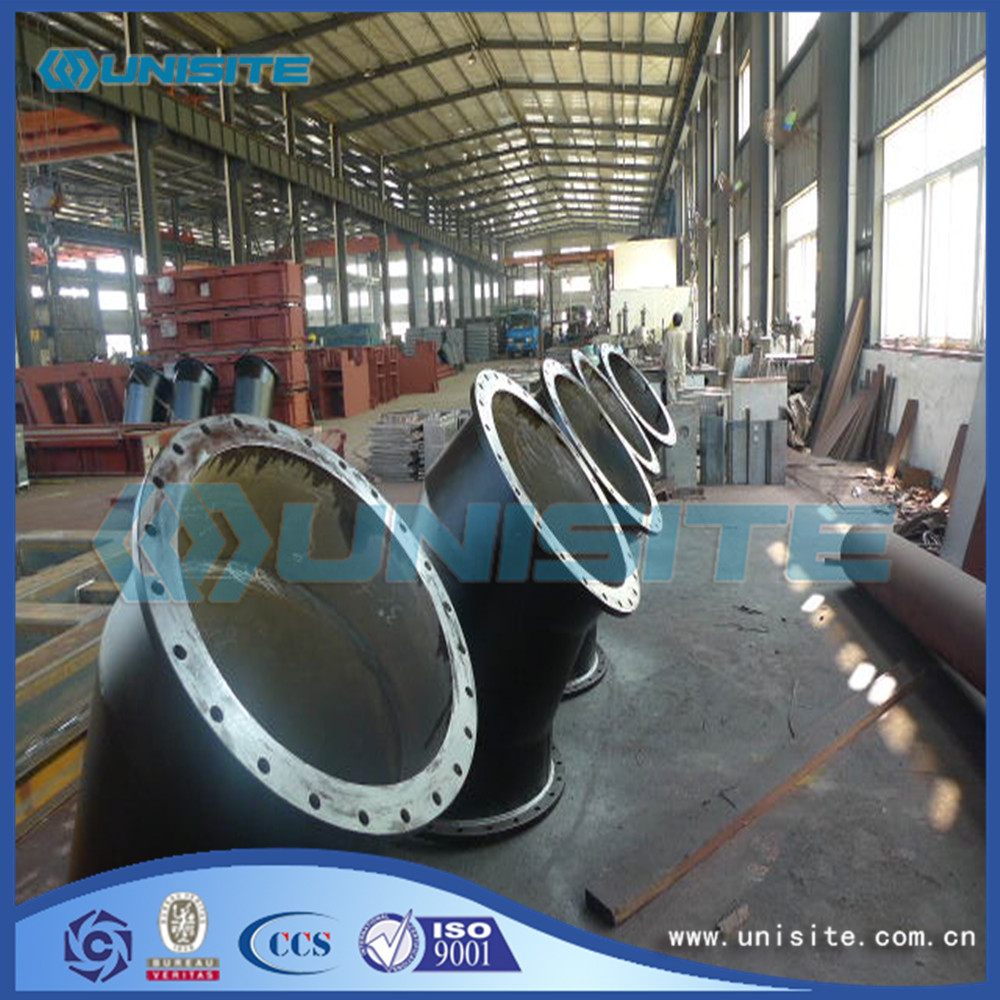

Tube parts butt welded, with or without flanges, to form high-precision bending and can be used to connect steel pipes

B. Construction

The construction is to be built according to the drawing with rules of good workmanship.

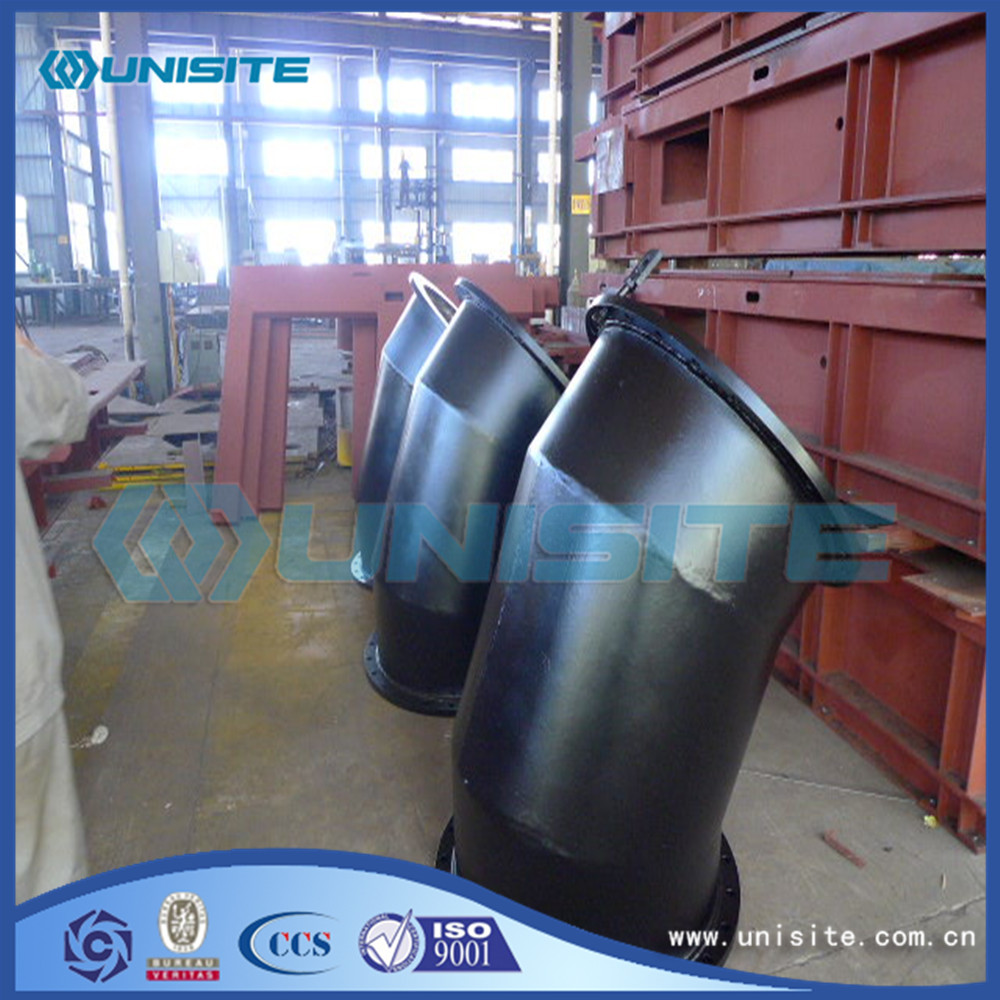

Lobster tail shape, CAF molding, assemble on the platform to ensure the dimensions.

High accuracy, in particular to ensure the angle, chord length and flanges.

C. Materials

All fabricated steelwork used in the construction of the bend will be to manufacturing standard of UniSite or other classification society.

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

D. Welding

All welding will be performed in accordance with drawing and order and UniSite experience and all welding will be continuous and full penetration.

Technology

Offering our client best possible and most sustainable solutions to their requirement. Production procedure:

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection;

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Other procedure if necessary;

Step5: Final dimension & NDT inspection for structure;

Step6: Machining if necessary;

Step7: Blasting and Painting with paint Hempel, Jotun, Inter, Sigma;

Step8: Package, Loading and Lashing when delivery;

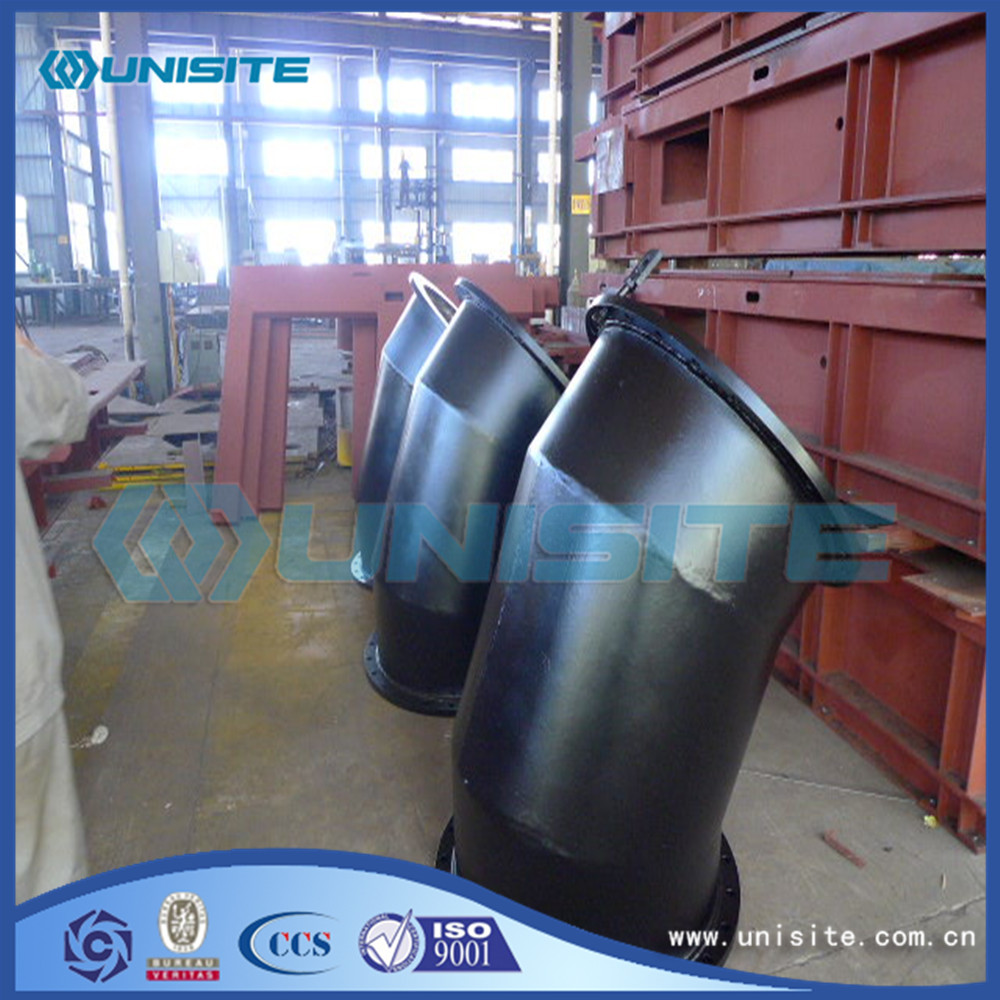

Photos of our Welding steel bend fittings

The group has a perfect managing system and our staff who are professional in technology are committed, passionate, efficient.

�Thanks to the knowledge, the experience and the skills of our work team, we are able to offer our client best possible and most sustainable solutions to their requirement.

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Pipe Bend > Welded Bend