Compared with the hot pushing process, stamping the appearance quality is inferior to the former; stamping elbow in the forming of arc in tension and other parts of excess metal is not the compensation, so outside the arc wall thickness reduction thin about 10%. However, due to the characteristics of the single piece production and low cost, the stamping elbow process is used for the manufacture of small batch and thick wall elbow.

Technology

In order to perform comprehensive service and relevant items to clients` satisfaction, UniSite knows the importance of advanced technology, equipment, quality and continuously invests in advanced production base and equipments.

The group has a perfect managing system and quality control system which from initial work, to process control, to final control, forming the whole process traceability with a good command of quality and production schedule.

Thanks to the knowledge, the experience, the skill and the advanced technology of the group, we are able to offer our client best possible and most sustainable solutions to their requirement.

Production equipment

UniSite continuously develops the whole production equipments including pipeline production equipments, machining equipments, material inspection equipments, welding equipments, bending press equipments, rolling equipments, cutting equipments which can be played maximum role in each project and service.

Vessel equipments Based on the strategic partnership with DONGPENG shipyard, UniSite has an extensive designing and construction system as well as some auxiliary ships and equipments which can be deployed in the optimal construction, repairing and maintenance system. Dredgers: Trailing suction hopper dredgers, Cutter suction dredgers, Backhoes dredgers, Bucket dredgers, Water injection dredgers, Hopper Barges. Special vessels: Chemical vessels, Tank vessels. Auxiliary equipment: Work boats, Pontoons, Barges, Fork truck, Crane, Heavy lifts, Gantry crane, Auxiliary machineries. Safety & Quality Whether we are able to offer our client best possible and most sustainable solutions to their requirement or to complete our mission, our safety & quality are the key factors. So that quality, health, safety and environment (QHSE) on site are given priority which includes setting our QHSE standards and production guidelines, in-house safety training to our staff, checking all the production equipments periodically, preventing pollution, accidents and health hazards, auditing and verifying whether our work is being executed according our certified system ISO 9001, CCS certificate.

We also organize site short meetings (SSM) when new productions and activities are being under taken and when working plans, technologies, qualities and methods are altered.

Thanks to these efforts and activities, we are able to perform our best works in an efficient way.

Photos of our equipments

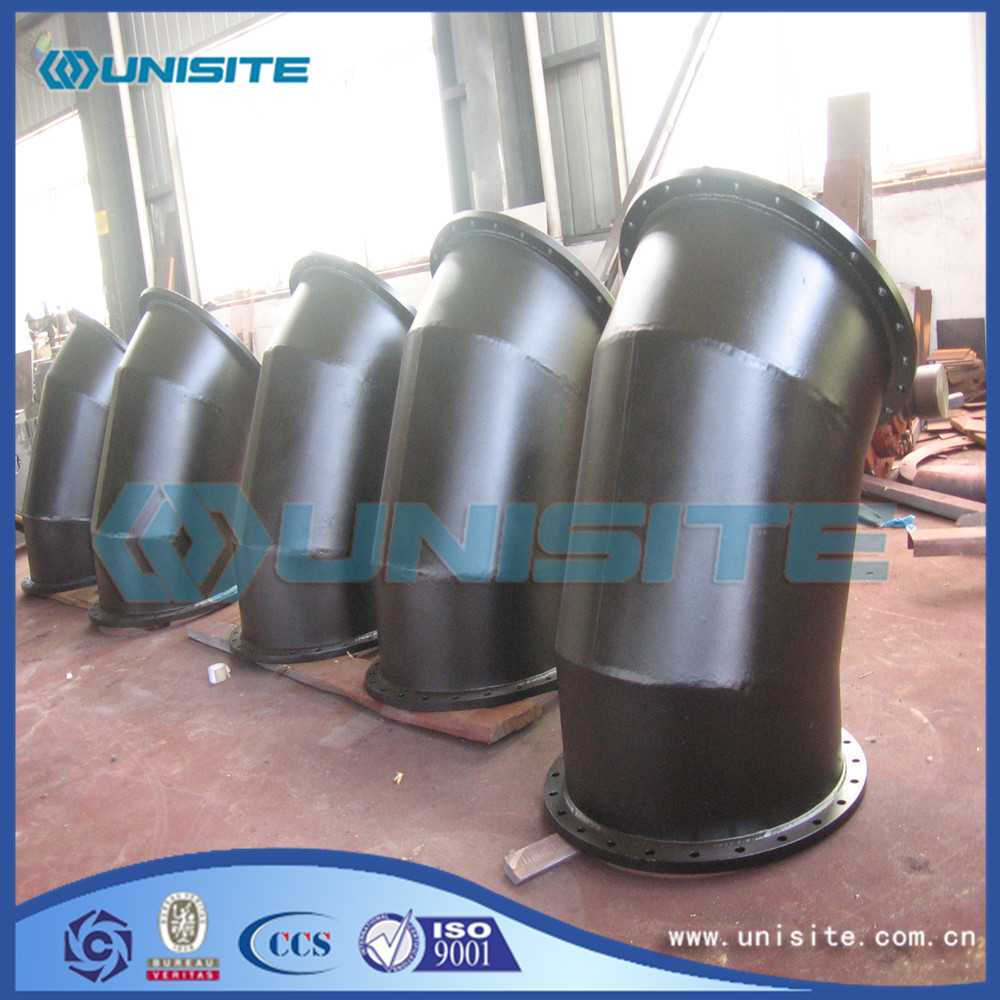

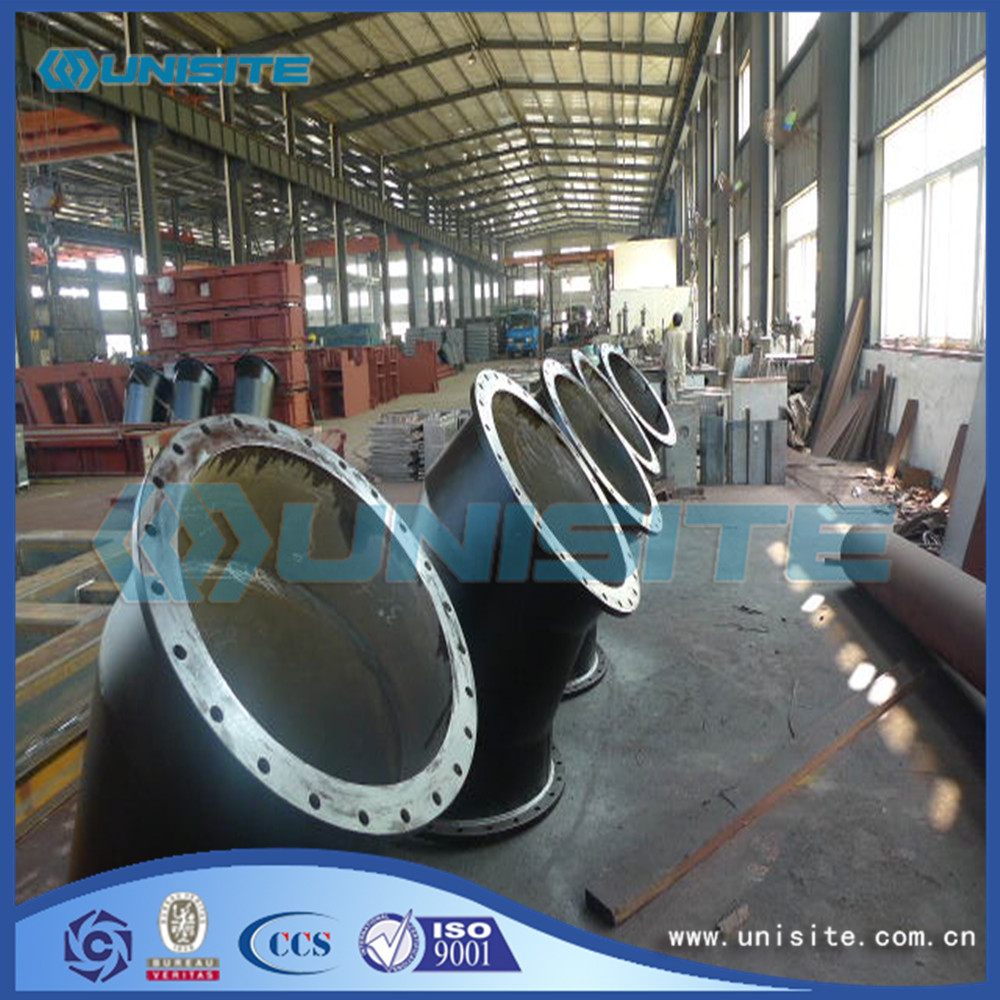

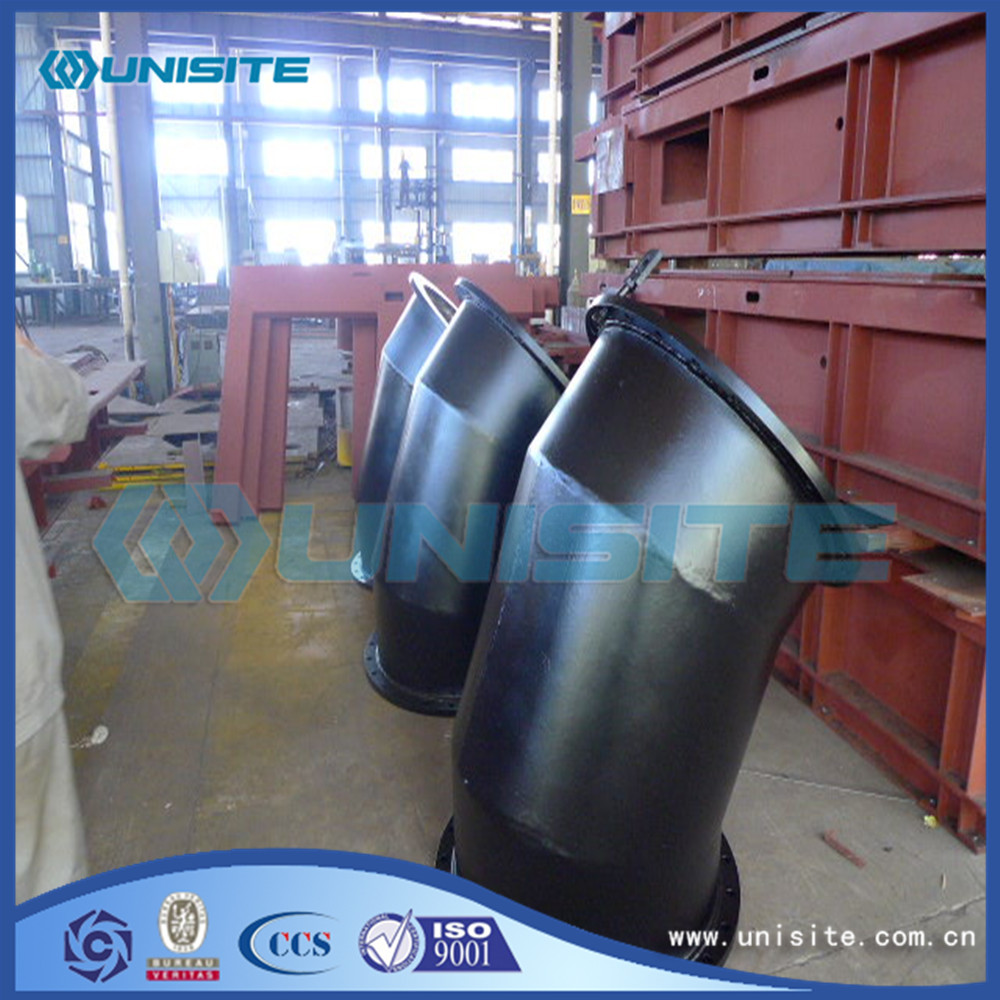

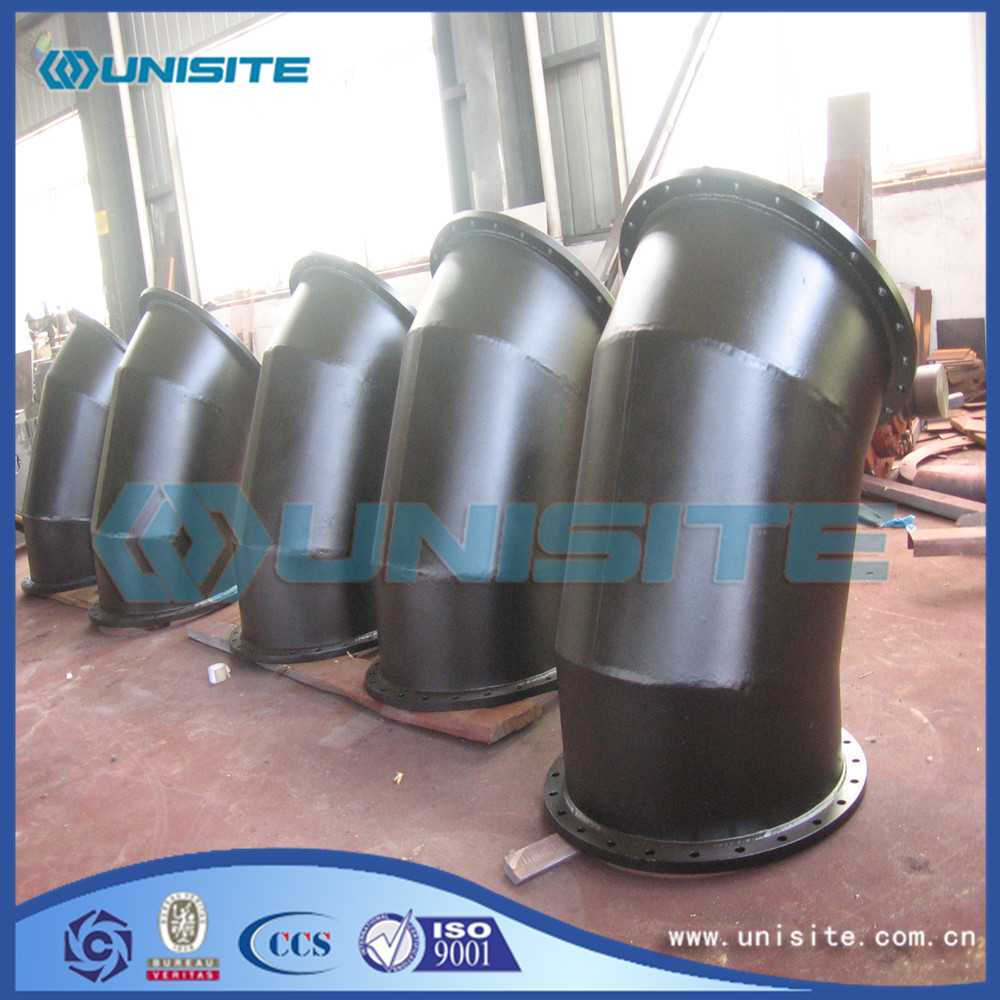

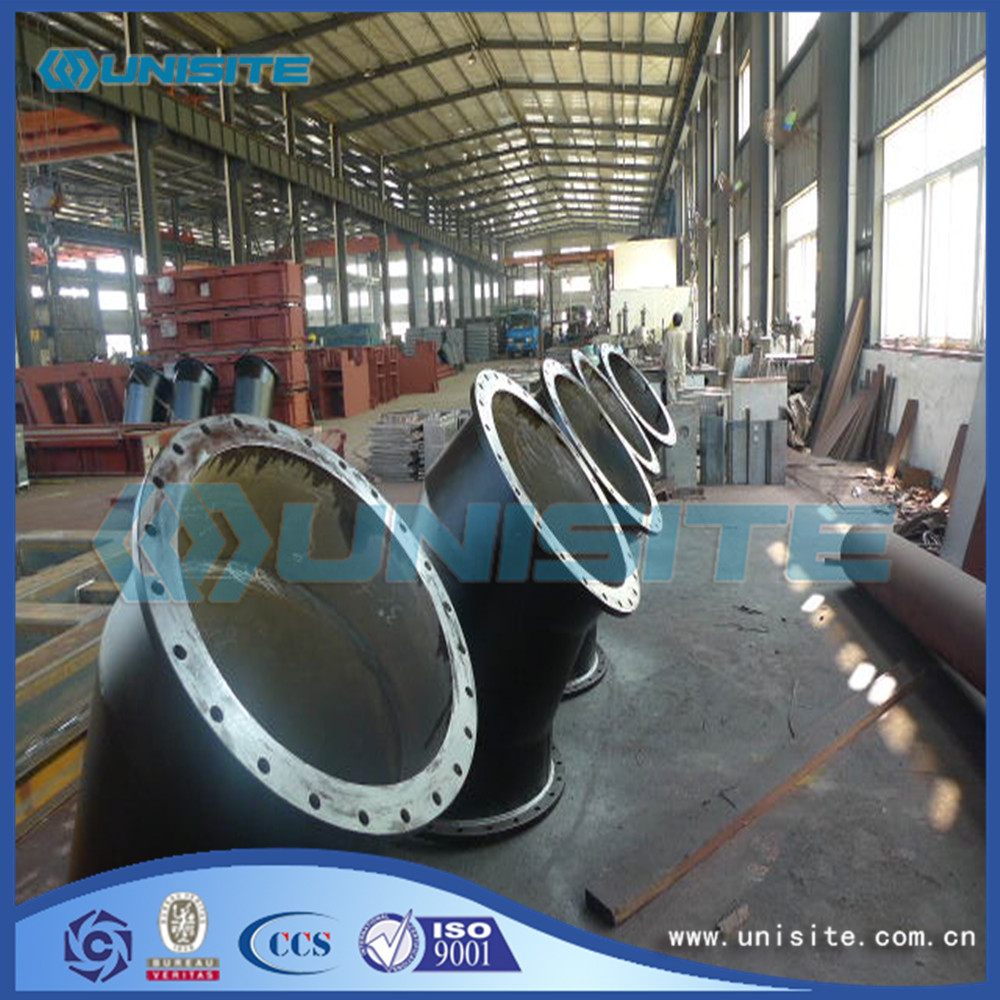

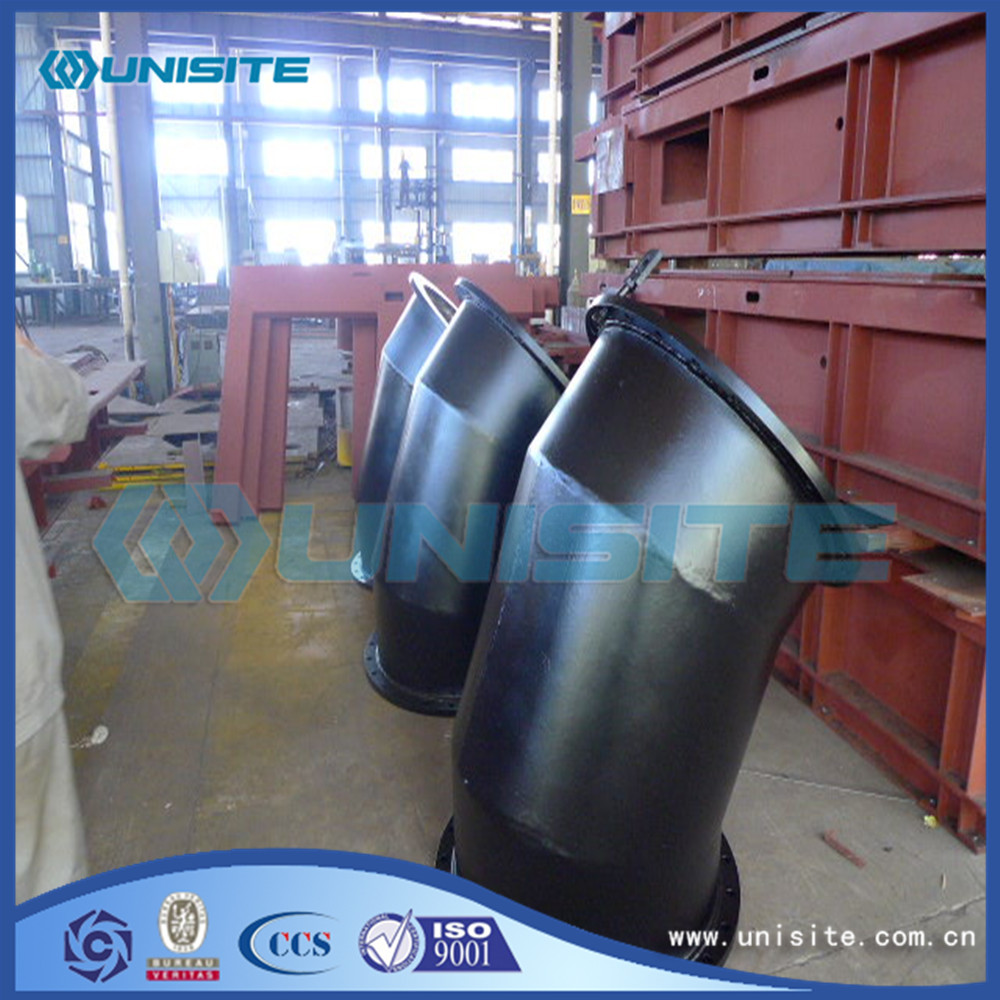

Photos of our Steel metal bending pipe fittings

Our service

Besides above the general specifications, we can also supply some specific bends and other similar steel structure as clients' requirements.

Package and shipping

Wooden Cases, Wooden Pallet or Neutral Boxes package and container transportation

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Pipe Bend > Welded Bend